- 636 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

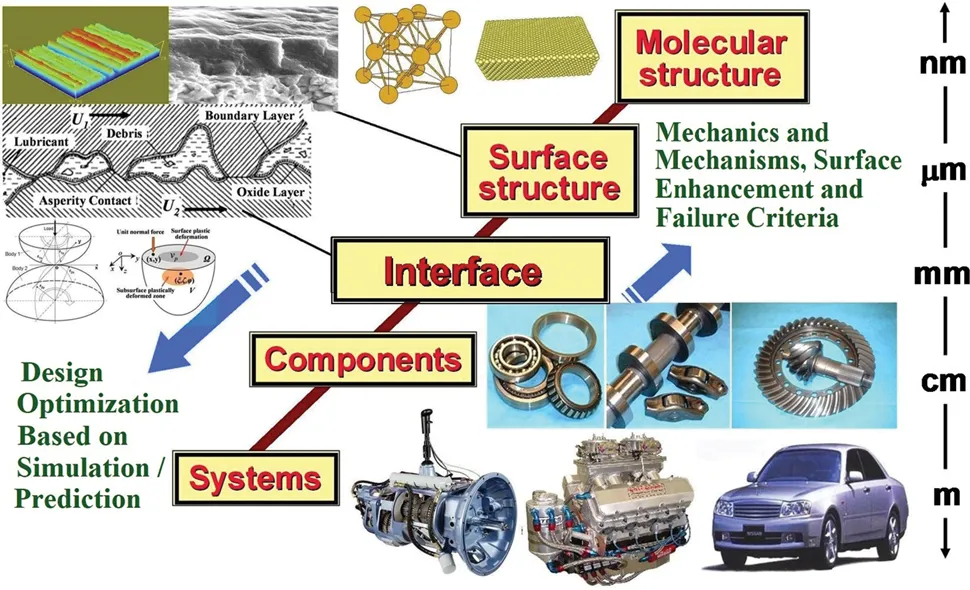

Understanding the characteristics of material contact and lubrication at tribological interfaces is of great importance to engineering researchers and machine designers. Traditionally, contact and lubrication are separately studied due to technical difficulties, although they often coexist in reality and they are actually on the same physical ground. Fast research advancements in recent years have enabled the development and application of unified models and numerical approaches to simulate contact and lubrication, merging their studies into the domain of Interfacial Mechanics.

This book provides updated information based on recent research progresses in related areas, which includes new concepts, theories, methods, and results for contact and lubrication problems involving elastic or inelastic materials, homogeneous or inhomogeneous contacting bodies, using stochastic or deterministic models for dealing with rough surfaces. It also contains unified models and numerical methods for mixed lubrication studies, analyses of interfacial frictional and thermal behaviors, as well as theories for studying the effects of multiple fields on interfacial characteristics. The book intends to reflect the recent trends of research by focusing on numerical simulation and problem solving techniques for practical interfaces of engineered surfaces and materials.

This book is written primarily for graduate and senior undergraduate students, engineers, and researchers in the fields of tribology, lubrication, surface engineering, materials science and engineering, and mechanical engineering.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1 Introduction

1.1 Significance of the Topics

1.2 Tribological Interface Systems

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgments

- Authors

- Nomenclature

- Chapter 1 Introduction

- Chapter 2 Properties of Engineering Materials and Surfaces

- Chapter 3 Fundamentals of Contact Mechanics

- Chapter 4 Numerical Methods for Solving Contact Problems

- Chapter 5 Fundamentals of Hydrodynamic Lubrication

- Chapter 6 Numerical Methods for Hydrodynamic Lubrication

- Chapter 7 Lubrication in Counterformal Contacts—Elastohydrodynamic Lubrication (EHL)

- Chapter 8 Mixed Lubrication with Rough Surfaces

- Chapter 9 Thermal Behaviors at Counterformal Contact Interfaces

- Chapter 10 Behaviors of Interfacial Friction

- Chapter 11 Contact of Elastoplastic and Inhomogeneous Materials

- Chapter 12 Plasto-Elastohydrodynamic Lubrication (PEHL)

- Chapter 13 EHL of Inhomogeneous Materials

- Chapter 14 Application Topics

- Chapter 15 Multifield Interfacial Issues and Generalized Contact Modeling

- Appendix A: Basic Expressions in Linear Elasticity

- Appendix B: Fourier Series, Fourier Transform, Convolution, and Correlation

- Appendix C: Solutions of the FRFs for Multilayered Materials Under Normal and Shear Loadings

- Appendix D: Reference Source Code in FORTRAN for Discrete Convolution and Fast Fourier Transform (DC-FFT)

- Appendix E: Basic Equations and Their Discretization Schemes for Numerical Solution of Mixed EHL

- Appendix F: Potential Functions, Derivatives, and Equations Used in Chapter 11

- Appendix G: Stresses and Surface Displacement Caused by a Cuboidal Inclusion with Uniformly Distributed Eigenstrain

- Appendix H: Material Property Parameters and Coefficients for the MEMCT Theory

- Appendix I: Frequency Response Functions for Surface-Source Induced Temperature and Thermal Elasticity

- References

- Index