![]()

1

HAND TOOLS

Hammers and Nails

Handsaws

Measuring, Marking, and Layout Tools

Chisels and Gouges

Hand Planes

Other Hand Tools

![]()

WOODWORKERS AND CARPENTERS have been in my family for generations. We have inherited a beautiful walnut bureau constructed by an ancestor for his wife around the turn of the century. When you examine it, including the turned side pedestals, it’s hard to imagine the massive furniture piece was constructed entirely with hand tools with the exception of the turnings, which were created on a foot-operated lathe.

If you spend any time in museums, you’ll appreciate the work with hand tools alone on projects, such as a Philadelphia Highboy, as well as any number of Chippendale pieces. I learned woodworking at my father’s side, and his first lessons were, of course, with hand tools. His thoughts were the basics should be with hand tools, and then you graduate to powered tools.

When I later began to teach woodworking, I followed his advice with my students. There is also something “connecting” in creating a project using only hand tools, especially when using an old tool handed down from fathers or grandfathers or purchased at a flea market. On the other hand, some hand tools are still the primary tool of use.

HAMMERS AND NAILS

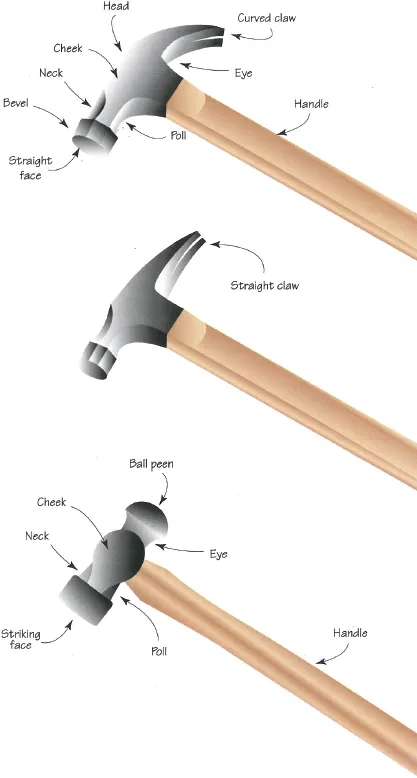

A hammer, in the form of a rock, was probably mankind’s first “tool.” Today hammers are just as important and are available in a wide range of types and sizes that are suited to specific chores. Hammers are also some of the most misused and abused tools. Although we often treat hammers as such, there is no such thing as a universal hammer. Hammers include nail or claw hammers, ball-peen hammers, sledges, blacksmith's hammers, magnetic hammers, and soft-face mallets. Choosing the proper hammer for each chore is important not only for safety, but also for the life of the hammer, the ease of use, and success in the chore. The most common hammers for woodworkers are nail or claw hammers.

Types of Hammers

Claw hammers should be used only with nonhardened common or finishing nails. These hammers are available in two styles: curved-claw with 16- or 20-ounce weights, used for general carpentry, and lighter 10- or 12-ounce weights, used for finish carpentry or cabinetry. Straight-claw hammers are sometimes called ripping hammers. The straight claw provides more leverage for pulling larger nails when doing framing or remodeling work. Straight-claw hammers commonly come in 20-, 24-, 28-, or 32-ounce sizes. The most common hammer is a curved-claw 16-ounce model. This hammer can be used for just about any carpentry, millwork, furniture construction, or home repair and maintenance. This size hammer can also drive everything from small brads to heavy nails, and the curved claw provides easy nail pulling of small- to medium-size nails.

Two other common sizes, however, can make specific chores easier. A 12- or 13-ounce hammer is ideal for cabinetry, millwork, and furniture building with small nails where it’s important not to mar the wood finish. A 20- or 24-ounce framing hammer is best if doing extensive house framing or remodeling. The larger hammer also has a longer handle for better balance and force in driving large nails. These hammers are available with a curved claw, but more commonly come with a straight claw, called a ripping claw. The ripping claw can be used to pry up boards, remove large nails, and perform other building and remodeling chores. Hammers are also like many other items, such as golf clubs. Even if you have a number of hammers to choose from, you’ll find one just seems to fit your hand and work style better than other hammers, and over time it becomes a companion you always pick up first.

Hammers parts

Don’t buy cheap hammers. A quality hammer has a forged head with a crowned or slightly curved face. Cheaper hammers are made with cast-iron heads, and the face is usually flat. The metal on the head will also be rough, not smooth. Cheaper hammers may even shatter and cause a serious injury. A crowned-face hammer can be used to drive finish nails down flush with the wood surface without denting the wood. The crowned head is also designed to present more surface to the nail with a normal arm swing, which helps drive nails straight without bending them. Hammer heads may be smooth or, for rough framing work, corrugated, which prevents the head from slipping off the nails in hard driving chores. Claw hammers are available with a variety of handle materials, including wood, steel, and fiberglass (or graphite). All three materials are excellent, but there are differences. Wood has a more natural feel and is the most economical. Fiberglass and especially graphite handles offer less vibration for day-long use, and the handle is usually wrapped with soft foam or rubber—another plus for extended use.

Nailing hammers are available in sizes from 10 to 32 ounces. They may feature curved- or straight-claw styles.

Handles may be straight or hatchet-style and made of wood, fiberglass, or metal with molded-over materials for comfort.

The Stanley contractor graded jacketed hammers feature a jacketed graphite handle with a special ribbed grip and a patent-pending head-to-handle assembly. Steel handles provide more power for large chores. The Craftsman solid-steel hammer features a patented wooden plug for shock absorption and a foam exterior. Most claw hammers feature a straight handle, but the California Framer hammers from Vaughn feature a hatchet-style handle. Their BlueMax model also has an innovative magnetic nail holding slot capable of holding 16d and 20d nails. These are great for starting nails in places you can’t reach with both hands. In addition, some hammers feature unusual head materials and designs. For instance, the Vaughan Ti-Tech Titanium hammer combines the speed driving power of titanium with the versatility of interchangeable steel caps. The lightweight titanium body swings faster for greater power at the point of impact with less stress and arm fatigue. The steel caps can be changed from milled face for rough framing to smooth face for finish work.

Many hammers feature antivibration design handles for day-long usage with fewer fatigue and joint problems.

The Vaughn Ti-Tech hammer features a titanium body with interchangeable steel caps.

Maintenance

Some hammer heads are held in place with one or more steel wedges. If the head becomes loose, you can often tighten it back in place by driving the wedge tighter. The first step is to hold the hammer upside down and rap sharply on the butt end of the handle. This will drive the head tighter. Then reseat the wedge by tapping in place.

The face of a hammer is extremely important and the part that causes the most trouble to the inexperienced. If you seem to be bending more nails than usual, look at the face. It might be scratched or covered with wood resin or dried glue. Place a piece of fine sandpaper flat on a workbench, and polish the face of it. Never grind the face of a hammer.

Other hammers include tack or magnetic hammers designed for driving tacks or brads. The specialty hammer shown is an antique in the author’s collection and used to drive glazing points in windows or pictures frames.

Magnetic and Tack Hammers

These small and lightweight hammers are primarily used to drive upholstery tacks. They are commonly double-faced with one face having a magnet inset. By placing a tack against the magnet, you can reach in and drive the tack in hard-to-get places. These small flat-faced hammers are also commonly used for driving glazing points to hold glass in windows or picture frames. In fact, a special glazing hammer features a swiveling head with a flat face on three sides.

A hammer face may become pitted or covered with wood resin or dried glue. Lightly sand the face with a piece of fine sandpaper held on a flat surface to restore the face.

Framing work requires heavy hammers that can drive larger nails with force. Many also feature longer, hatchet-style handles.

Mallets

Soft-faced hammers and mallets come in several sizes, shapes, and materials. They are available with rubber, hard plastic, and rawhide faces. The primary uses of these mallets are for wood chisels and carving chisels. They can also be used to tap in dowels, drive glued joints together for clamping, or for...