- 208 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Landfill Bioreactor Design & Operation

About this book

Using biotechnology to help control landfill processes can mitigate costs, shorten the time needed to process solid waste, and ease the typical ecological damage to the land being used. This first-of-its-kind book provides regulators, designers, landfill owners, and operators with information that supports the utility of landfill bioreactors and provides design and operating criteria essential for the successful application of this technology. It pulls together laboratory, pilot, and full-scale experiences into one concise guide to designing and running municipal landfills as bioreactors. Landfill Bioreactor Design and Operation covers the history and background of landfill technology, research studies of actual bioreactor landfills, expected leachate and gas yields, specific design criteria, operation guidelines, and reuse of landfill sites to avoid having to establish new sites. For anyone looking for an alternative to large, wasteful landfill sites, this book provides a practical alternative to the problem.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Landfill Bioreactor Design & Operation by Timothy G. Townsend,Debra R. Reinhart in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Environmental Science. We have over one million books available in our catalogue for you to explore.

Information

1

INTRODUCTION

SCOPE AND OBJECTIVES

While the typical person may think otherwise, the modern municipal solid waste (MSW) landfill has evolved into a sophisticated facility. The state-of-the-art landfill can be loosely categorized into four classes. The secure landfill tends to entomb wastes, perhaps postponing any environmental impact to the future when environmental controls and safeguards initially provided fail. The monofill accepts waste that cannot be processed otherwise through resource recovery, composting, or incineration. These materials tend to be inert and may be more easily assimilated by the environment. At present, the monofill is used for disposal of combustion ash, construction and demolition debris, and yard waste. The reusable landfill permits excavation of the landfill contents to recover metals, glass, plastics, other combustibles, compost and, potentially, the site itself following a lengthy stabilization period. A fourth, emerging landfill type, is the bioreactor landfill, which is operated in a manner to minimize environmental impact while optimizing waste degradation processes. It is this type of landfill that is the focus of this book.

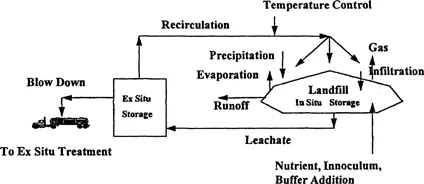

Bioreactor landfills are constructed in a manner similar to most modern sanitary landfills — they are equipped with liners and leachate collection systems. Bioreactor landfills, however, are operated and controlled to rapidly accelerate the biological stabilization of the landfilled waste. Fig. 1.1 provides a schematic of a typical bioreactor landfill operation. The fundamental process used for waste treatment in a bioreactor landfill is leachate recirculation. Recirculation, or recycle, of leachate back to the landfill creates the environment favorable to rapid microbial decomposition of the biodegradable solid waste. The landfill becomes a treatment system rather than simply a storage facility. Bioreactor operation thus provides additional protection of the environment and may reduce long-term liability and associated monitoring costs. The rapid treatment of the waste also facilitates the operation of a bioreactor landfill as a reusable landfill. The combined operation of rapid waste treatment followed by reclamation of the stabilized landfill material results in a system that may dramatically extend the operating life beyond that of a traditional landfill.

Figure 1.1 Schematic diagram of the landfill bioreactor.

Laboratory and pilot-scale studies have clearly demonstrated that operation of a landfill as a bioreactor accelerates waste degradation, provides in situ treatment of leachate, enhances gas production rates, and promotes rapid settlement. Full-scale evidence of bioreactor landfill benefits is rapidly accumulating. However, many challenges still face the implementation of bioreactor technology, including regulator reluctance to permit such facilities, the availability of theoretical design criteria, the ability to uniformly wet the waste, and operator training issues. The objective is to provide the regulator, designer, landfill owner, and operator with information and data that support the utility of the landfill bioreactor and provide design and operating criteria essential for the successful application of this technology.

THE EVOLUTION OF LANDFILLS FOR WASTE MANAGEMENT

The landfill, as we know it, has evolved from a long tradition of land disposal of MSW, dating back to prehistoric times. Problems with land disposal began as society developed and population density increased. Land disposal of waste — often as open dumps — was subject to aesthetic, safety, and health problems that prompted innovations in design and operation. Environmental impacts associated with MSW landfills have complicated siting, construction, and operation of the modern landfill. Production of leachate has lead to documented cases of groundwater and surface water pollution. Landfill gas emissions can lead to malodorous circumstances, adverse health effects, explosive conditions, and global warming. Traffic, dust, animal and insect vectors of disease, and noise often are objectionable to nearby neighbors. These issues have lead to strict regulation of landfill disposal of MSW.

Ideally, land should be a repository exclusively for inert “earthlike” materials that can be assimilated without adverse environmental impact, a conviction held by landfill regulators, designers, and operators through-out the world.1 However, successful application of this concept requires extensive waste processing to develop an acceptable product for land disposal, and faces challenges related to public opposition, economics, waste handling, and transportation of recovered materials. The most reasonable scenario for success appears to be a MSW management park, where regional facilities for managing waste — from separation to resource recovery/reuse to incineration to landfilling — would be collec-tively sited.

While disposal solely of inert materials may be an admirable objective, it will be some time, if ever, before this concept can be universally applied. Therefore, it is likely that landfills will continue to receive a variety of materials with potential for environmental impact. A second global consensus is that where leachable materials are land disposed, impenetrable barriers must be provided and waste stabilization must be enhanced and accelerated so as to occur within the life of these barriers. That is, the landfill must be designed and operated as a bioreactor. Additional advantages of the bioreactor landfill include increased gas production rates over a shorter duration, improved leachate quality, and more rapid landfill settlement.

LANDFILLS AS BIOREACTORS

Under proper conditions, the rate of MSW biodegradation can be stimulated and enhanced. Environmental conditions that most significantly impact biodegradation include pH, temperature, nutrients, absence of toxins, moisture content, particle size, and oxidation-reduction potential. One of the most critical parameters affecting MSW biodegradation has been found to be moisture content. Moisture content can be most practically controlled via leachate recirculation. Leachate recirculation provides a means of optimizing environmental conditions within the landfill to provide enhanced stabilization of landfill contents as well as treatment of moisture moving through the fill. The numerous advantages of leachate recirculation include distribution of nutrients and enzymes, pH buffering, dilution of inhibitory compounds, recycling and distribution of methanogens, liquid storage, and evaporation opportunities at low additional construction and operating cost. It has been suggested that leachate recirculation can reduce the time required for landfill stabilization from several decades to two to three years.2

Implementation of bioreactor technology requires modification of design and operational criteria normally associated with traditional land-filling. For example, the bottom liner system must be designed to accommodate the additional flows contributed by leachate recirculation. The gas management facilities must be operated to control amplified gas production, particularly during the active landfill phase. Overcompaction of waste during placement may adversely impact leachate routing and prevent even moisture distribution. Use of permeable alternative daily cover is recommended for similar reasons. Leachate recirculation devices must be employed which are compatible with daily operation and closure requirements. Monitoring of leachate and gas quality and quantity becomes critical to operational decision making. Even waste pretreatment, such as shredding or screening, may be desirable to promote biological and chemical landfill processes. Leachate management must be carefully planned to ensure adequate supply for recirculation during dry weather conditions, and on the other extreme, to prevent saturation of waste during wet weather periods. Chronological changes in leachate characteristics will impact ex situ treatment and disposal requirements as a result of in situ treatment of degradable organics, as well as many hazardous leachate constituents.

REGULATORY STATUS

Regulations promulgated under Subtitle D of the Resources Conservation and Recovery Act (RCRA) allow leachate recirculation, provided a composite liner and leachate collection system are included in the design. In the preamble to Subtitle D regulations, implemented in 1991,3 EPA commented that:

… EPA recognizes that landfills are, in effect, biological systems that require moisture for decomposition to occur and that this moisture promotes decomposition of the wastes and stabilization of the landfill. Therefore, adding liquids may promote stabilization of the unit…

Specifically, Section 258.28(b) (2) of CFR Part 258, “Criteria for Municipal Solid Waste Landfills” states the following:

Bulk or noncontainerized liquid waste may not be placed in a municipal solid waste landfill unit unless … the waste is leachate or gas condensate derived from the municipal solid waste landfill unit and the landfill unit is equipped with a composite liner and a leachate collection system that is designed and constructed to maintain less than a 30-cm depth of leachate over the liner.

A telephone poll of U.S. state regulatory agencies conducted in late 1992 and early 1993 found that full-scale operation of leachate recirculation was practiced (or would be soon) in 12 states and was permissible in all but seven states. Recirculation facilities were in place at landfills in eight states, under construction at landfills in four states, and planned at landfills in several other states. For the most part, states merely adopted RCRA criteria regarding leachate recirculation, requiring a composite liner in order to implement leachate recirculation.

A few states identified additional, more stringent criteria for leachate recirculation. For example, Florida, Georgia, Pennsylvania, and Virginia specifically address odor prevention. Florida requires that gas management facilities be in place prior to commencement of leachate recirculation. New York requires a double composite liner for all MSW landfills. Pennsylvania and Georgia require that the leachate recirculation piping system be installed under a permeable intermediate cover. Virginia, New York, Georgia, and Florida require control of runoff and prohibit ponding. Georgia also requires that sufficient waste be in place to provide sufficient moisture absorption prior to initiating recirculation.

Those states that prohibited leachate recirculation did so for several reasons. Regulators cited a lack of confidence in the method, interference with the leachate collection system, geological and climate concerns, freezing problems, leachate seepage, lack of waste absorptive capacity, and exacerbated gas and odor production.

ORGANIZATION OF THE BOOK

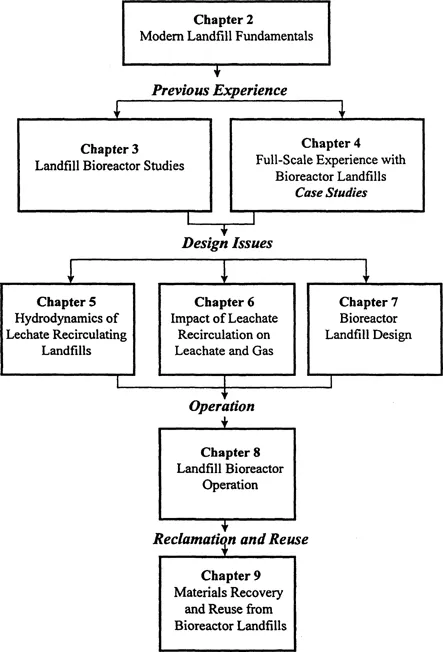

The long term acceptance of bioreactor landfills as tools in integrated solid waste management systems requires that such facilities be designed and operated in a safe and effective manner. Numerous studies have been performed investigating this technology, and this text serves to bring this information together, so that future bioreactor systems may benefit from the lessons gained from previous work. This text summarizes existing information available regarding the design and operation of bioreactor landfills and should serve as a resource to engineers, regulators, and all parties interested in the technology. The content and organization of the book are indicated in Fig. 1.2. In addition to a review of modern sanitary landfill fundamentals, sections cover the results of previous bioreactor landfill operations experiments, including a series of case studies; describe design and operation issues; and discuss the potential of landfill mining as a method to recover treated waste materials and to reuse the bioreactor cells.

Figure 1.2 Organization of book.

2

MODERN LANDFILL FUNDAMENTALS

INTRODUCTION

A discussion of bioreactor landfills and the use of leachate recirculation as a method of leachate management must begin with an overview of the fundamentals of modern landfill design and operation. Most leachate recirculation operations performed to date have been conducted at traditionally designed landfills. In the future, successful leachate recirculation systems will be engineered as part of an integrated bioreactor landfill design. This chapter provides the reader with a background in the fundamental elements involved in the design of a modern sanitary landfill.

The design and operation of a modern landfill involves many science and engineering disciplines, including the biology and chemistry of waste decomposition and leachate production, as well as the hydraulic, geotechnical, and materials engineering required for the design of liners, pipes, and pumps. While an introduction is provided here...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- The Authors

- Preface

- Acknowledgments

- Table of Contents

- Chapter 1 —Introduction

- Chapter 2 —Modern Landfill Fundamentals

- Chapter 3 —Landfill Bioreactor Studies

- Chapter 4 —Full-Scale Experiences with Bioreactor Landfills — Case Studies

- Chapter 5 —The Hydrodynamics of Leachate in Recirculating Landfills

- Chapter 6 —The Impact of Leachate Recirculation on Leachate and Gas Characteristics

- Chapter 7 —Landfill Bioreactor Design

- Chapter 8 —Landfill Bioreactor Operation

- Chapter 9 —Materials Recovery and Reuse from Bioreactor Landfills

- References

- Index