eBook - ePub

Woodwork for Beginners

With Instructions and Illustrations on Basic Woodworking Skills, Including Information on Tools, Timber and Simple Joints - The Handyman's Book of Woodworking

- 266 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Woodwork for Beginners

With Instructions and Illustrations on Basic Woodworking Skills, Including Information on Tools, Timber and Simple Joints - The Handyman's Book of Woodworking

About this book

"Woodwork for Beginners" is a comprehensive guide to woodwork designed for those with little previous experience. This fantastic introduction covers all of the basic skills and techniques related to the subject, with chapters on the proper use and care of tools, types of timber, the fundamental joints, and much more. Profusely illustrated and full of expert tips, this classic handbook is not to be missed by those looking for an introduction to woodworking and related subjects. Paul Nooncree Hasluck (1854 – 1916) was an Australian engineer and editor. He was a master of technical writing and father of the 'do-it-yourself' book, producing many books on subjects including engineering, handicrafts, woodwork, and more. Other notable works by this author include: "Treatise on the Tools Employed in the Art of Turning" (1881), "The Wrath-Jobber's Handy Book" (1887), and "Screw-Threads and Methods of Producing Them" (1887). Many vintage books such as this are increasingly scarce and expensive. It is with this in mind that we are republishing this volume now in an affordable, modern, high-quality edition complete with a specially-commissioned new biography of the author.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Woodwork for Beginners by Paul N. Hasluck in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Technical & Manufacturing Trades. We have over one million books available in our catalogue for you to explore.

Information

JOINTS.

SHOOTING EDGES OF BOARDS.

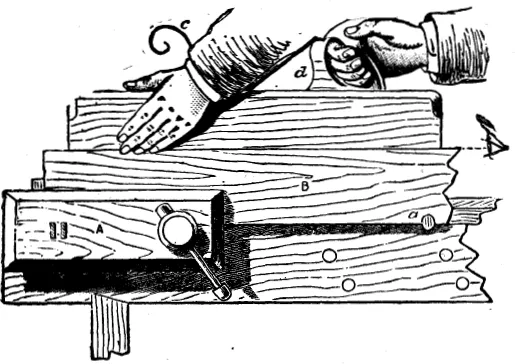

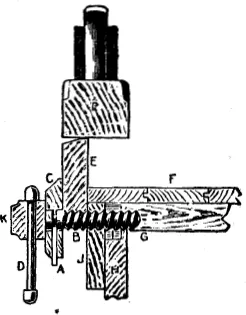

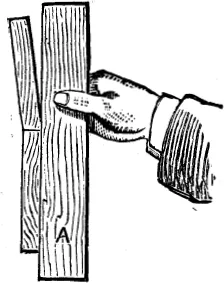

Before even plain glued butt joints can be attempted, there are one or two processes, not yet described, with which the beginner must familiarise himself. The first of these is shooting edges—that is, planing the edges of boards until they are square and true. Ordinary planing has already been discussed (see pp. 48 to 51). Insert a pin, made in the form of a hook, into one of the holes in the side of the bench, as at a (Fig. 540). The edge of the board B is then placed upon the hook, and the other end securely fastened in the bench vice, A. Fig. 540 shows this in front view, and Fig. 541 in end view. The edge is now planed first with the jack plane, and afterwards with the trying plane, until straight as viewed from the end, the edge being frequently tested with a square (as in Fig. 542). The trying plane is held in the manner shown in Fig. 540, the fingers of the left hand acting as a guide to keep it in position. The shavings should pass freely, as at c, and be taken off the whole length of board to finish. Fig. 541 shows the application of the jack plane to the edge of the board. In that illustration F indicates the bench top; C, vice; B, bench screw; K, head of screw; D, handle; A, stop; J, side of bench; H, leg; G, bearer; E, board; and P, the plane. For accurate work the shooting board is used; varieties of this appliance are illustrated and described on pp. 12 to 15. The work is placed on the bed of the shooting board, and a plane in good condition is shot along its edge, which is thus reduced to perfect truth.

Fig. 540.—Shooting Edge of Board.

Fig. 541.—End View of Shooting Plane and Board.

GAUGING BOARD TO THICKNESS.

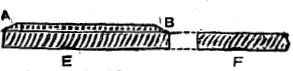

A board to be reduced in thickness has first to be gauged along its edges. Set the marking gauge with its tooth at a distance from the head equal to the thinnest part of the board, and, grasping it firmly, work it along the edges of the board in a succession of short, sharp strokes, keeping the head firmly pressed to the face side of the board. Having gauged the board, roughly chamfer the edges nearly down to the line, as A B (Fig. 543), E being the face side. Now plane away the stuff until level, as at F. This, though completing it so far as the trueness of its surface is concerned, may yet leave it in a very rough state. The grain may have been strong and ripped up, or the irons of the planes may not have been in perfect condition, thus leaving marks or ridges. These have to be cleaned off with the smoothing plane (see p. 50).

GLUED JOINTS.

The glued joint is adopted where it is desired to make a number of narrow boards serve as one wide one. For instance, table-tops, panels of doors, and many other things, are made preferably by gluing up rather than by using one wide board. The plain glued butt joint, shown by Fig. 544, is serviceable enough for thin wood, say for anything under 1/2 in. thick, and, in certain situations, suffices for material of any substance. When the wood is thick enough something better than a butt joint can be used. With thin stuff, however, this is the only joint available, as there is no room for tongues or dowels. The plain glued butt joint will be considered first; then the stronger and more serviceable dowelled joint, and that formed by ploughing and cross tongueing, will be dealt with. A properly glued butt joint ought to be stronger than the natural wood; that is to say, a board should split at any part rather than the joint, except perhaps in the case of some tough woods. With ordinary pine or bay wood, if the fracture is along the joint, this proves that the workmanship or the glue is at fault. Under a severe strain a board often will give way, leaving the joint unbroken, it being actually stronger than the wood itself.

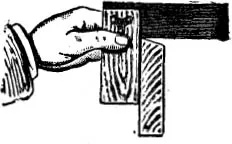

Fig. 542.—Testing Squareness of Shot Edge.

Fig. 543.—Board Chamfered and Planed to Thickness.

PREPARING BOARDS FOR JOINTING.

For first efforts at making a plain butt joint (Fig. 544) get two pieces of board, say about 2 ft. long, and not less than 1 in. thick. Plane up the board true and out of winding, always remembering to pencil the face mark upon the finished surface. Shoot the edges perfectly straight, true, and square, or at right angles to the face side; they should then be placed one upon the other (the bottom board to be in the bench vice), and a small straight-edge (A, Fig. 545) applied to the face to test the joint for “upright.” It will often occur that the boards “tip,” as shown. This will, of course, have to be rectified by shooting one or both edges. The boards being upright, the joint should be so placed that the light is thrown upon the back, when it is seen at once if the boards touch all along the joint. If they do not touch at one or two places, make a pencil mark upon the face where the bumps occur, and carefully take off a shaving at these points. The top board (A, Fig. 546) may then be taken in both hands, as shown, and gently rubbed along the other, and the feel will indicate if their edges are in good contact. Occasionally the edges touch at opposite corners, and then a little must be taken off each, the edge being in winding. The plane-iron for shooting joints should be very sharp and finely set, as this will add greatly to the ease with which a good joint can be made. In the case of very long joints, say from 6 ft. to 8 ft., some workmen allow the boards to touch at the ends, but not towards the centre; if the space is but small no great harm will result. They consider this space advisable for long pieces. To convey an idea of the hollowness of the edge towards the centre, assume two boards 5 ft. or 6 ft. long, with edges perfectly true. Now with the plane remove a shaving or two, just the suspicion of one at its commencement, a few inches from the end of the board, till there is, when the boards are placed together, a perceptible space between them tapering from the centre to nothing near the ends. Even at the widest the space must be narrow enough to be closed by pressure of the cramps, within which the boards will be placed while the glue is setting.

Fig. 544.—Plain Glued Butt Joint.

Table of contents

- Cover

- Title

- Copyright

- Contents

- Half title

- I Geometric Tools

- II Holding Tools

- III Paring and Shaving Tools

- IV Hand Saws

- V Tools of Percussion and Impulsion

- VI Boring Tools

- VII Abrading and Scraping Tools

- VIII Nails, Screws and Glue

- IV Timber : Its Growth, Seasoning, Conversion, Selection and Varieties

- X Joints

- XI Easy Examples of Woodwork