eBook - ePub

Ploughing Machinery on the Farm - A Collection of Articles on the Operation and Maintenance of Ploughs

- 142 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Ploughing Machinery on the Farm - A Collection of Articles on the Operation and Maintenance of Ploughs

About this book

This antique book contains a collection of articles on the operation and maintenance of ploughs. It contains a wealth of timeless and practical information that will be of much interest to the farmer. Complete with detailed illustrations and interesting insights, this text makes for a worthy addition to agricultural libraries - and will be of considerable value to collectors of antiquarian farming literature. The articles of this compendium include: 'Farm Implements'; 'Farm Machinery'; 'Farm Machinery and Tractors'; 'Repairing Farm Machinery'; and 'The Operation, Care, and Repair of Farm Machinery'. We are proud to republish this vintage text, now complete with a new introduction on farming.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Ploughing Machinery on the Farm - A Collection of Articles on the Operation and Maintenance of Ploughs by Various in PDF and/or ePUB format, as well as other popular books in Tecnologia e ingegneria & Agricoltura. We have over one million books available in our catalogue for you to explore.

Information

USE THE INSTRUCTION BOOK FOR THIS MACHINE

REPAIRING THE WALKING PLOW

The walking plow is a complicated piece of farm equipment. It was built originally to operate satisfactorily, provided the adjustments were properly made for the existing conditions. Continued use has the effect of disturbing some of the adjustments made by the manufacturer. Breakage and bending occur, as well as wear. By following the proper procedure, and making necessary repairs and adjustments, the walking plow can be made to function as satisfactorily as it did when new.

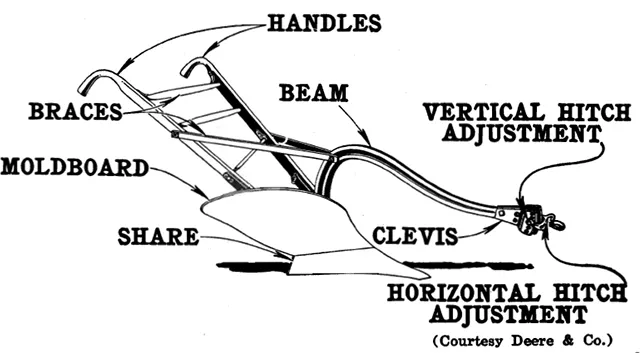

Fig. 36.—Common type of walking plow with important parts named.

Special Equipment: Coarse, large power emery grinder, forge and forging tools.

Directions:

Make a list and order parts that are needed. See Job 1, “Repairing the Mower.”

Steel beams frequently become bent, causing the plow to run to one side or to “bob” up and down, which produces a poor job of plowing, and is tiring to the team and to the plowman.

1. Examine the plow beam to see whether or not it is straight.

a. Have the plow standing in its normal plowing position.

(Courtesy N. Y. State Col. of Agriculture.)

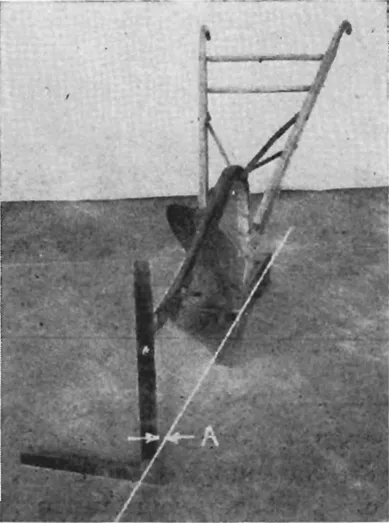

Fig. 37.—Checking for beams sprung sideways. To check for a beam sprung sideways, stretch a string against the upper part of the landside. Place a square so that the edge is in line with the middle of the plow beam. Measure the distance A. For a two-horse beam this distance should be 1 1/2 inches. For a three-horse beam, the string should touch the square.

b. Proceed as directed under Figure 37.

c. If you discover that the beam is bent or sprung, it should be straightened or replaced with a new one.

Note: If the plow does not stay in the ground with a good share, it is possible that the beam is sprung up.

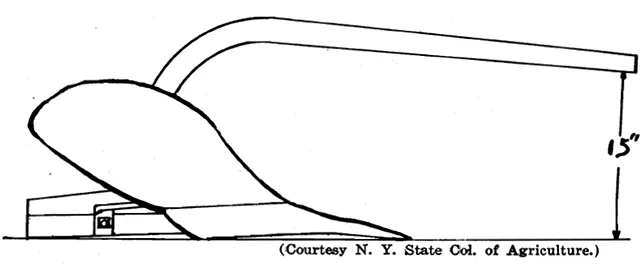

d. Use a new share and measure from the underside of the beam, at the extreme end, to the floor. This should be approximately 15″ for all walking plows, regardless of make.

e. If the above measurement is 16″ or more, the beam is sprung up and should be replaced or straightened.

Fig. 38—Checking sprung beams on a horse plow. By measuring from the floor to the under side of the beam, one can determine whether the beam has been sprung up. The distance should be between 14 and 16 inches.

2. Straighten a bent steel plow beam.

a. Remove the depth gauge wheel and clamp.

b. Remove the coulter or jointer.

c. Remove the beam from the frog.

d. Place the beam on the forge with the bend in the fire.

e. Heat slowly to a cherry red, and hold at this heat until the heated beam is the same temperature throughout, usually three or four minutes will be enough. Do not over-heat.

f. Place the beam on the anvil and strike the bend with a heavy hammer until the beam is straight.

g. Allow the beam to cool slowly and completely.

h. Replace the beam on the plow.

Wood beams on plows frequently become damaged by rotting, splitting, or by being cracked or broken.

Wood beams on plows frequently become damaged by rotting, splitting, or by being cracked or broken.

3. Examine the wooden beam for damage.

4. If the beam is still serviceable, tighten all bolts, or replace them with new ones. Use larger bolts if necessary.

5. If the beam is damaged, replace it with a new one.

6. Remove rust on the moldboard, share and landside with a wire brush, pumice stone and water, soft brick or emery cloth.

Moldboards are commonly made of chilled cast iron, or of soft center steel. Each material has its specific use. Moldboards wear badly and should be replaced, although the wear is ordinarily slow, and replacement is made at infrequent intervals.

Moldboards are commonly made of chilled cast iron, or of soft center steel. Each material has its specific use. Moldboards wear badly and should be replaced, although the wear is ordinarily slow, and replacement is made at infrequent intervals.

Fig. 39—Down suction in a plow share.

7. Inspect the moldboard and determine if it is serviceable. Replace it if it is badly worn.

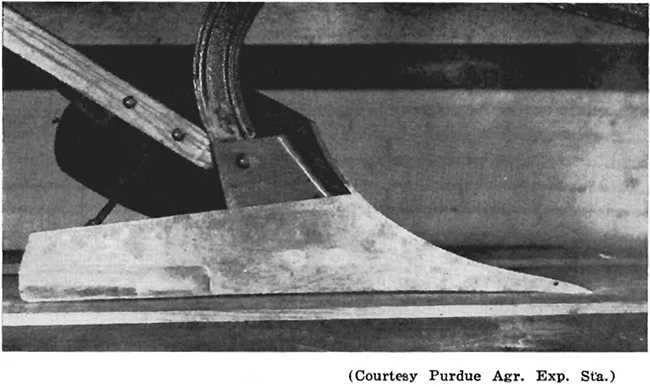

Shares and landsides are usually made of the same kind of material as the moldboard, although sometimes a solid steel share is used with a soft center steel moldboard. These parts are more subject to wear and breakage than the moldboard, consequently need more attention. Shares are constructed with “land suck” and “down suck” in order that the plow may travel in a steady, smooth manner. “Down suck” is obtained by building the point of the share lower than the rest of it. When the share is resting flat on the floor, a space should be noticed between the floor and the bottom of the land side, back of the point. This space indicates the amount of down suction.

If the share is in good condition this space will be between 1/16 and 1/8 inch. About the same space should be noticed at the front of the share, back of the point in the bend or throat.

Shares and landsides are usually made of the same kind of material as the moldboard, although sometimes a solid steel share is used with a soft center steel moldboard. These parts are more subject to wear and breakage than the moldboard, consequently need more attention. Shares are constructed with “land suck” and “down suck” in order that the plow may travel in a steady, smooth manner. “Down suck” is obtained by building the point of the share lower than the rest of it. When the share is resting flat on the floor, a space should be noticed between the floor and the bottom of the land side, back of the point. This space indicates the amount of down suction.

If the share is in good condition this space will be between 1/16 and 1/8 inch. About the same space should be noticed at the front of the share, back of the point in the bend or throat.

Fig. 40—Land suction in a plow share.

To determine “land suck” place the share on the plow in its proper working position. A straight edge touching the point and the landside should leave a space back of the point. This indicates “land suck” or the amount the point is bent towards the unplowed land. It should be about 14 inch for the walking plow.

Another point on the plow share is of importance on the walking plow. This is at the under side of the rear point of the cutting edge and is called the “wing bearing”. The wing bearing serves to hold the plow bottom level. This feature is not found on wheeled plows.

8. Sharpening plow shares.

a. Soft center solid steel shares may be heated at the forge and drawn to approximately their original shape by striking with the hammer while the share is a deep cherry red color. This is a very exacting, highly specialized job, and should not be undertaken by the amateur, but should be done by an expert plow smith.

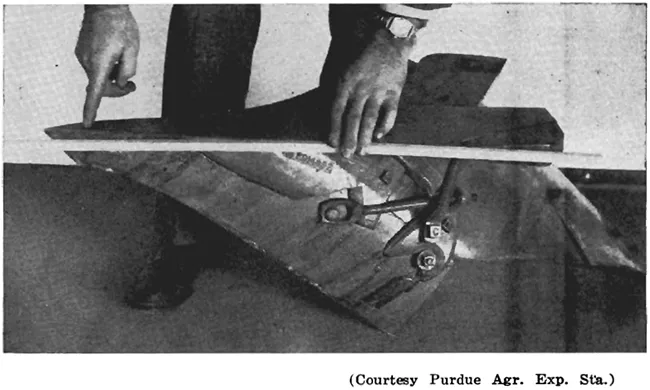

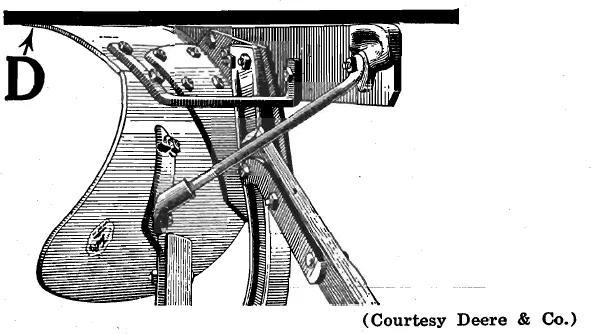

Fig. 41—Wing bearing, point “D”, is necessary to smooth running of walking plows.

b. The point of the steel share may be...

Table of contents

- Cover

- Title

- Copyright

- Agricultural Tools and Machinery

- Contents

- Farm Implements. Anon

- Farm Machinery. Claude Culpin

- Farm Machinery and Tractors. R. H. Cochrane

- Repairing Farm Machinery. Ivan G. Morrison

- The Operation, Care, and Repair of Farm Machinery. Anon