![]()

1 | Introduction to Tool Steels |

Various aspects of tool steels are presented and discussed in this book. This chapter will first guide the reader on the main attributes of tool steels, how this class of materials may be segmented, and how the main metallurgical aspects are interconnected. Starting with the definition of tool steels, this chapter then introduces the four main groups of tool steels, which will form the base for the discussion in the subsequent chapters. And this division is based on the final tooling application, rather than on composition or other metallurgical aspects.

Therefore, despite addressing the properties, microstructure, and manufacturing in depth, this book will be driven by understanding the performance on each application of the especially very interesting class of ferrous materials called tool steels. In this introductory chapter, tool steels are defined, the main standards used for them are described, and the classification of tool steels is presented, which will be the same classification followed in the next chapters.

1.1 DEFINITION OF TOOL STEELS

Before starting to write on any topic, the first attempt is to try to find a precise definition for it in order to establish the rationale for separating it from other areas. This will be the purpose of this chapter, which gives the initial directions on tool steels.

A precise definition of tool steels, however, is not found in the literature. Tool steels do not correspond to a specific chemical composition or have a specific set of properties or applications. One of the best definitions found in the literature is given in the excellent book of Roberts et al. [1], when citing the description of “Tool Steels” in the Steel Products Manual of Iron and Steel Society:

Tool steels are (1) carbon-, alloy-, or high-speed steels, capable of being hardened and tempered. They are usually melted in electric furnaces and (2) produced under tool steel practice to meet special requirements. They may be used in certain hand tools or in mechanical fixtures for (3) cutting, shaping, forming, and blanking of materials at either ordinary or elevated temperatures. Tool steels are also used in a wide variety of other applications where resistance to wear, strength, toughness, and other properties are selected for optimum performance.

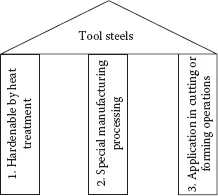

This description is composed of three major elements, which are numbered according to the transcription from Iron Steel Society text, reference [2], and summarized in Figure 1.1. The first element of the above definition points to the fact that tool steels may show a wide range of chemical compositions, from very low alloy grades to compositions with extremely high amounts of alloy elements. But one characteristic is common to all these groups: their ability to enhance the properties by means of heat treatment, especially by hardening and tempering. This characteristic is very remarkable indeed in tool steels, as it represents a tremendous enhancement in their properties after hardening and tempering. For example, tool steels are perhaps the only class of materials in nature that are able to cut themselves: a hardened high-speed steel tool is capable of drilling bars also made of high-speed steel when those are in the untreated or, more precisely speaking, annealed form. This potential provided by the heat treatment of tool steels also makes the latter dependent on the application of proper heat-treatment conditions, which also depend on their metallurgical aspect. In this sense, Chapter 3 will deal with all the metallurgical features of different tool steels and include an in-depth discussion on their heat-treatment aspect.

FIGURE 1.1 Schematic representation of the main pillars that define tool steels.

The second part of the definition of tool steels concerns the manufacturing methods used to produce a tool steel in the steel mill. When compared to the amount of carbon and low-alloy steels produced, which is in the range of two billion tons per year, tool steels are a very small group and represent about 0.1% of that (probably around two million tons per year, worldwide, depending on which grades are classified as tool steels). This lower volume produced means that tool steel production methods may be different from those of large-volume steels due to simple scale factors. In addition, the superior properties required of tool steels creates the need for careful control of their process and, in most cases, addition of manufacturing operations that are not common in other steels. So, these manufacturing aspects of tool steels also differentiate them from other steels, constituting the second pillar in the definition of tool steels detailed in Chapter 2.

The last aspect in defining a tool steel is the final application: used for shaping, forming, or cutting ferrous alloys, other metallic alloys, and other nonmetallic materials, at room temperature or high temperatures (usually up to 1200°C). The range of applications of tool steels is therefore very wide and also large while combining the steel grades, heat treatment conditions, and manufacturing methods, in addition to tool mechanical design. This characteristic is probably the most important topic in this book and is used to group different types of tool steels within groups for a given application: cold work tool steels, hot work tool steels, plastic mold tool steels, and high-speed cutting tool steels, the last group being well known only for high-speed steels. These aspects are then described in the next section of this introductory chapter and are used to describe the specific characteristics of each group in later chapters (Chapters 4 through 7).

1.2 DESIGNATION OF TOOL STEELS

There are many different designations for tool steels, based on different standards in different countries (e.g., United States, China, Europe/Germany, Japan) and also commercial designations based on proprietary compositions, or simply different names for marketing purposes. Therefore, it is never easy to define precisely the tool steel by looking at its name; nor is it easy to compare steels from different standards and different manufactures. Some books or encyclopedias may help in that respect, gathering most of the grades and their typical composition, such as the Stahlschluessel, which means “key to steels” (see Reference 3); although it is a German title, it has an English text content.

One of the main classification methods for tool steels is the ASTM (American Society for Testing and Materials) designation [4,5], where each steel grade is named by a letter followed by a number. The letter means one characteristic of the tool steel, and the number, usually in sequential (and usually historical) order, denotes a given developed steel. Table 1.1 shows all letter designations in the ASTM group of tool steels. For example, the tool steel A2 means that it belongs to the “Air-hardenable group” of tool steels. In steel H13, however, the letter “H” refers to its application, namely in hot-forming processes. And, as a last example, in the steel M2, the letter M refers to the element molybdenum, which is the main alloying element providing the properties of hot hardness and wear resistance in cutting tools and thus having a chemical composition relation. So it is clear that there is no single parameter for gr...