eBook - ePub

Fundamentals of Work Measurement

What Every Engineer Should Know

Anil Mital, Anoop Desai, Aashi Mital

This is a test

Share book

- 210 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Fundamentals of Work Measurement

What Every Engineer Should Know

Anil Mital, Anoop Desai, Aashi Mital

Book details

Book preview

Table of contents

Citations

About This Book

This book will provide a quick reference on Work Measurement. While the nature of the work may differ, measuring work is fundamental to any industrial or service activity. It's needed to determine such things as the amount a person should be paid, how much time should it take to perform an activity, what is an acceptable days' work, or how any two or more methods or designs compare. This book provides non-industrial engineers with the why and the how work is measured in order to perform their jobs.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Fundamentals of Work Measurement an online PDF/ePUB?

Yes, you can access Fundamentals of Work Measurement by Anil Mital, Anoop Desai, Aashi Mital in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ingeniería industrial. We have over one million books available in our catalogue for you to explore.

Information

1 Introduction: Significance of Work Measurement

1.1 WHAT IS WORK?

Work is defined as purposeful or intentional activity that is undertaken, or physical or mental effort that is exerted by an individual in order to accomplish something. This “something” could be making objects or accomplishing tasks of varying difficulties. Therefore, cooking, writing, fetching water, painting, doing craft work, building infrastructure (houses, bridges, etc.), making furniture or artifacts, sewing garments, shaping materials to achieve specific objectives, etc. are all examples of purposeful activities that are defined as “work.”

To accomplish any task or activity, often referred to as “work” or “jobs,” effort is required. This effort is typically measured in terms of time it takes to complete the activity or the work contained within it (sometimes this effort may be measured in terms of time a person can sustain an activity—endurance time).

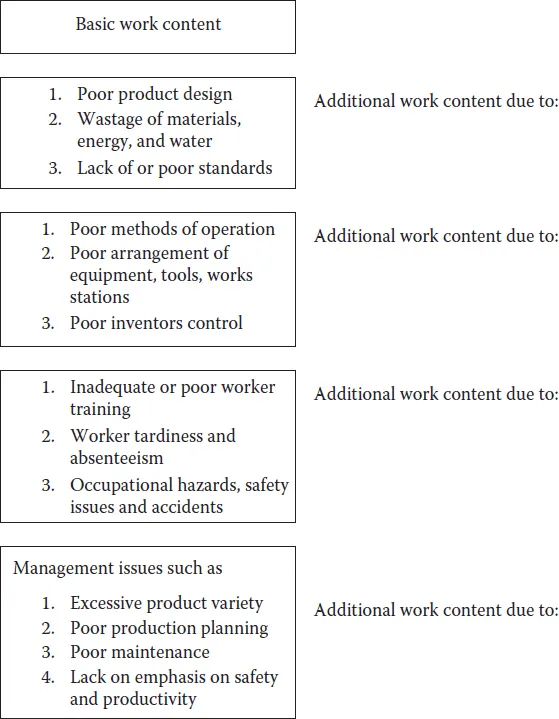

There are two components to the work that is contained in any activity:

- The basic work content of the activity

- Additional, or excess, work content

The basic work content is defined as the minimum effort as measured by the time it takes to complete an activity. This amount of time is the theoretical minimum time required to produce the object of interest or complete the process and cannot be reduced. Conditions must be perfect so that the required effort is the “minimum” possible. In reality, such an occurrence would be unlikely if not impossible. Even if it was possible to eliminate all excess work content, it may not always be desirable to do so for various reasons, including the ability to respond to unexpected breakdowns or prescribed maintenance.

The activity completion time that is required in practice is increased due to the inclusion of additional work content. This additional work content is the result of inefficiencies introduced by factors as follows:

- Poor design of the product

- Poor choice of the process

- Poor choice of material or its utilization

- Poor utilization of the primary and support processes

- The worker and the management

In practice, the increase in work content (time) introduced by these inefficiencies may be reduced to approach the basic work content (theoretical minimum time required) but can never be achieved. Figure 1.1 shows the basic and additional work content of completing an activity or making an object. The following section briefly discusses certain key factors that add to the basic work content.

1.2 FACTORS ADDING WORK CONTENT TO A PRODUCT (OR ACTIVITY)

1.2.1 Product Design

A product is intended to provide function(s) that the buyers require and features that they desire. Providing these functions and features at a price that people are willing to pay and the reliability of the function a product is expected to provide are critical requirements that a product must achieve. A product with numerous components made up of diverse materials and relying on fasteners, such as screws, leads to increased work content. As a general rule, the number and the types of materials used in a product should be minimized. Instead of using fasteners, such as screws and nuts or bolts, it is recommended to use snap-in type of fasteners.

Figure 1.1 Basic and additional, or excess, work content.

On the other hand, a product with too few components increases the complexity of components and tends to reduce its reliability (failure to provide the function when needed). This eventually leads to increased product cost, thus making it economically less desirable. A good product design provides a balance between cost and reliability.

There are also considerations such as handling and the orientation of the components over the course of the product manufacture. Parts that are easy to grasp have high feedability (can be oriented in a number of acceptable ways due to the symmetry or only in a very specific way due to extreme asymmetry), and are self-locating to reduce the work content.

1.2.2 Lack of Standardization and Incorrect Quality Standards

A large number of nonstandard parts not only increase the assembly time but also lead to inventory problems (storing multiple parts, several vendors, and supply chain issues). Nonstandard parts lead to increased costs as such parts cannot be easily procured (off-the-shelf vs specially made parts). Components should be standard or standardized as much as possible to take advantage of the economy of the scale. This aids in managing the supply chain by allowing many vendors vs a few (too few vendors can create the possibility of supply chain shocks).

The quality standards are critical as well. If the quality standards are too high (narrow tolerances), then additional processing of materials may be required, thus adding to the work content. If the process is not in control, then this could lead to many parts being rejected, as they would fall outside the acceptable regions. Narrow tolerances, on the other hand, could lead to fewer parts containing defects and thereby increasing reliability. Too loose quality standards (wide tolerances) could result in large number of defective products and parts with low reliability. It is worth mentioning that tight control on processes has made it possible to achieve high quality standards and increased parts’ reliability in recent years. This, however, has not solved the problem of material removal, like that of machining, to achieve tight quality control. Therefore, choosing the right quality standard is essential in controlling the work content.

1.2.3 Poor Choice of Process or Method of Operation

Poor choice of manufacturing process, methods of handling or maintenance, inefficient method of work can all add to the work content. For instance, using machining instead of injection molding or net- or near-net shape casting can add to the processing time. Use of inappropriate material handling equipment, such as using forklifts instead of conveyor belt to move materials continuously, adds to the total time as does the use of poor preventive maintenance policies that lead to frequent equipment breakdown and work stoppage.

Furthermore, work methods that are tedious and cumbersome add to the excess time. Consequently, all methods must be analyzed for improvement and reduction of nonproductive time.

Equally important are issues that deal with the utilization of space. Proper planning of the facility to ensure smooth flow of materials is critical. This saves time and money by reducing effort.

1.2.4 Reducing Waste

Reducing waste, be it of materials, energy, water, or labor, is crucial to reducing the work content. Such expenditures are a reflection on the additional work content. Products, processes, and activities must be analyzed to ensure that minimal amounts of materials and supplies, including those of water, energy, and labor, are utilized. Additionally, materials that are removed during manufacture are recycled.

Designing products for “end-of-life” is the norm in modern enterprises. A “product recovery” approach needs to be utilized at the end of the life of a product. The recovery must be at the product level, module level, part level, and material level. The options could be

Repair—restore to working condition

Refurbishing—improve to quality level, though not like new

Remanufacturing—restore to quality level, as new

Cannibalization—limited recovery

Recycling—reuse materials only

The objective is to recover as much as possible the economic as well as the ecological value of products, components, and materials, in order to minimize the ultimate quantity of waste. If a component is repaired and reused, the ultimate work content gets distributed over a larger quantity.

The argument applies to the conservation of energy and water as well. Not all sources of energy are equally economical—energy from natural gas may be cheaper than energy from oil in some locations. The use of economical sources of energy, energy-efficient equipment, tools, and processes is an important consideration.

Reducing excess wastage of water in processes, recycling water, and replacing processes that are water intensive are also critical. Not only can water be expensive, but it may also be a scarce resource in areas suffering from drought or areas that have high population density.

Methods that are inefficient and waste energy or water are examples of poor product design and excess work content.

1.2.5 Poor Management and Poor Worker Performance

Examples of poor management are

- Poorly designed and poorly performing products

- Too many products, poor ecological value of products and too many varieties

- Poor maintenance

- Poor utilization of space, equipment, and tools

- Poor production planning and control

- Inadequate safety and poor health policies

Some of the causes of poor worker performance are

- Inadequate and improper training

- Lack of discipline and supervisory control, causing work delays, etc.

- Absenteeism and tardiness

- Lack of responsibility

These factors, directly or indirectly, influence the work content and need to be controlled or mitigated. Our intent is not to discuss how to accomplish that but to highlight how the work content and thereby the completion time are affected by these factors.

1.3 WHAT IS WORK MEASUREMENT?

In the most basic form, work measurement is defined as the application of techniques that determine the time it takes a qualified worker to carry out a task at a determined rate of working. In other words, work measurement is the determination of the duration a task takes (time/task). The British Standards Institution established this definition of work measurement in 1991 (Br...