- 109 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The book provides a qualified and fast view into the world of TPE including the difference to rubber materials. It describes their classification as they are presented in the market, characterization, manufacturing, processing and behavior. Aside from the self-learning option, it is a companion to seminars and studies about elastomers.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Thermoplastic Elastomers by Günter Scholz,Manuela Gehringer in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemistry. We have over one million books available in our catalogue for you to explore.

Information

1 Introduction to TPE

Among the thermoplastic elastomers (TPE), inherently two different molecular structures exist; these are the compounds of polymeric materials TPO (thermoplastic polyolefin) and TPV (thermoplastic vulcanizate) and the amorphous or semicrystalline copolymers TPO (olefinic block copolymer), TPS (styrene block copolymers), TPU (urethane block copolymer), TPC (ester block copolymer), and TPA (amide block copolymer). It sounds strange that TPO is visible in both classes, but there is a project close to be finished in the ISO committee to clarify this ambiguity situation. A new draft standard is published, which is the normalized standard (norm) DIN EN ISO 18064, where even the general definition of TPE is disclosed. It is “a polymer, or blend of polymers, that has properties at its service temperature similar to those of vulcanized rubber but can be processed and reprocessed at an elevated temperature like a thermoplastic.”

Even other polymer mixtures are possible to put under this definition. Such compounds are labeled as TPZ (elastomeric polymer blends). This part will not be introduced in this book because this would exist as a stand-alone topic. It is complex enough in TPS, TPO, and TPV chapters to discuss compounds because these materials are almost solely used as polymer blends in technical applications. Unless otherwise stated, properties and applications of TPS and TPV only include blends.

Considering the typical structure of a TPE copolymer with a crystalline or amorphous hard phase connected to a flexible soft phase, one could imagine an elastomer with a chemically bonded filler at nanoscale dimension (see Fig. 1.1). And this is, in fact, the truth. The “filler” melts at elevated temperature and the amorphous section softens like a glass. It can be interpreted as a physical network that is completely different from a chemically cross-linked vulcanized rubber.

Fig. 1.1: Structure of a semicrystalline TPE.

Every chapter about the single TPE contains a part concerning the processing. That is important because the processing conditions have a significant influence on the mechanical properties of the resulting parts. Mainly, the processes of extrusion and injection molding will be discussed. They are the incumbent methods for TPE. Of course, the TPE enter into the trendsetting technologies of additive manufacturing like sintering or filament printing, to name but the most usual ones. On the other hand, TPE are expandable during the melt processing by the well-known methods, which is gas injection or adding of foaming agents. Even particle foams of different TPE are established in the market.

1.1 Rubber

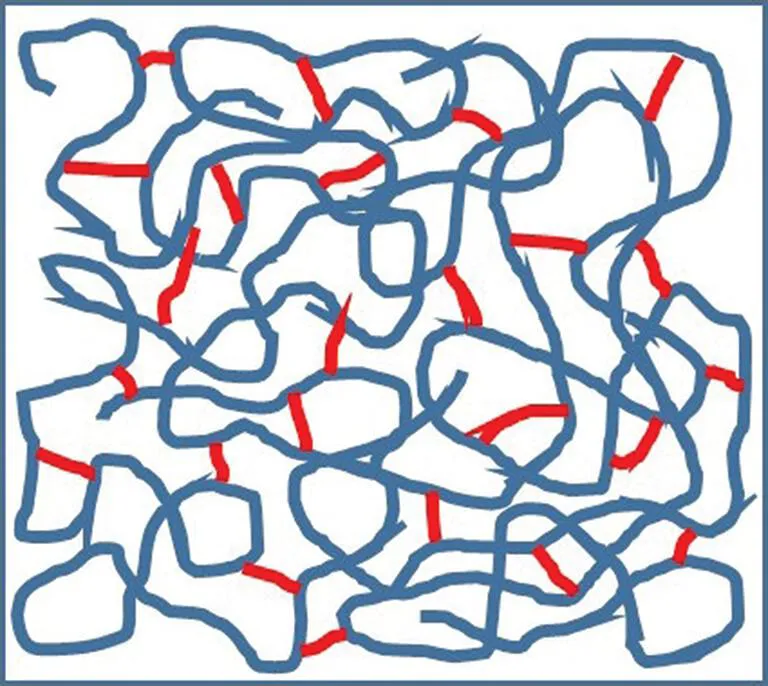

In official communication, the term thermoplastic rubber is sometimes used, which is slightly confusing because a TPE is mentioned. Vulcanized rubber is always chemically cross-linked (Fig. 1.2) and can no longer be melted. The typical large volume rubbers like SBR (styrene–butadiene rubber), NR (natural rubber), or BR (butadiene rubber) have high molecular weight for technical application, which are barely achievable for TPE. During rubber processing to make rubber mixtures, the material will be degraded to bring in all the components and finally produce a vulcanized elastomer. After the cross-linking process, the chain length of the rubber is reduced which makes the material stiffer, depending on the density of cross-linking. Without this process, the rubber would flow under mechanical load.

Fig. 1.2: Structure of a vulcanized rubber.

The recipe influences the hardness of such an elastomer and can range from soft, for elastic rods, to rigid, for golf ball cores. To maintain the elasticity while achieving an appropriate firmness, mineral fillers are used, for example, in car tires, active carbon black is added, which essentially acts as a semibound hard phase. Besides providing wear resistance, such a filler reduces the material degradation by UV light. All this has an influence on hardness and the elastic behavior of a made rubber. Achieving an easier handling or reduced material cost, inactive fillers are used as well, when the property request allows it.

NR and BR have a linear olefinic backbone and only a small degree of cross-linking is required to achieve a typical rubber elasticity which is characterized by high rebound forces and low deformation at high elongation. The molecular chains seek the lowest energy conformation, which is the statistical coil and it is called the entropic elasticity. Such materials closely follow Hooke’s law – in which the relation between elongation and force is linear – which is visualized by an ideal spring. This behavior is connected to a good cold flexibility. NR or BR have a low freezing temperature around −100°C, typically referred to as the glass transition because the coils do not crystallize, rather they solidify like a glass. In general, elastomers should have a certain amount of elasticity below 0°C and should not break under mechanical load or upon impact above the glass transition.

Besides the soft elastic character of most of rubber materials, the covalent bond of cross-linking ensures that the polymer does not melt. This property provides a good dimensional stability at elevated temperature, which means a good heat distortion temperature. This is the primary difference from TPE. On the other hand, this also means that it is not possible to melt a vulcanized rubber for thermoplastic processing. This is a very important aspect in the non-neglecting environmental discussion, here the recycling. This is much easier for TPE, whether in the first step of reusing waste or non-conformant material in the plant already, which reduces the material cost as well. In the second step, used parts from the market can be reprocessed to make new TPE pieces. Another aspect is the cost advantage due to faster processing and easier handling of TPE pellets compared to rubber strips, the preproduct before transforming to final parts and the vulcanization step. Related to one of the biggest application field, the overmolding of a soft TPE on a rigid thermoplastic, they show these aspects very clearly.

This application (Fig. 1.3) sounds trivial, but nearly everybody is using it. No one can imagine not to have a soft grip on the toothbrush. The manufacturing in a multicomponent injection molding opens a good opportunity of a balanced cost–benefit balance and a lot of design possibilities.

Fig. 1.3: Toothbrush from a rigid ABS overmolded with TPS of Kraiburg TPE (source: First Thai Brush).

Chapter 3 gives a deeper look into the difference of these both elastomer classes.

1.2 PVC-P (PVC plasticized)

Polyvinylchloride (PVC) is a rigid thermoplastic material and needs a high amount of plasticizer to make it soft and elastic. It can be included into the family of TPE, but this polymer compound has existed for many years before TPE appeared, and PVC-P (PVC plasticized) remains as a material in the group of thermoplastics. Concerning cold flexibility and the elastic behavior, there is a little difference between PVC-P and TPE, but it is important to consider this material as it is used in similar applications as TPE.

When a user is looking for an alternative to PVC-P, TPE products are considered to be suitable. Of course, PVC is quite unbeatable regarding the price–performance ratio. It is easy to process when the temperature is not too high, the mechanical properties are often good enough, and its resistance against a variety of substances makes this material attractive. The environmental concern of PVC pollution, the sensitivity to corrosion during processing, and the possible migration of the plasticizer drive the desire to seek an alternative. Even the use of organic plasticizer is under discussion in the public. Furthermore, when PVC burns, dioxides are created, which are highly toxic. For all the aforementioned reasons, it is worthwhile to seek for and consider about alternatives.

1.3 Olefinic polymer compounds

The predominant polymer mixture of a TPO is a thermoplastic matrix of polypropylene (PP) and an unsaturated rubber like ethylene–propylene–diene copolymer (EPDM) or a saturated ethylene–propylene copolymer, made on a twin-screw extruder. The concentration of rubber is high, in order to provide a flexible material rather than an impact-modified thermoplastic. However, it is difficult to define a specific cutoff in these two regimes. In the case of more than 50% of rubber, EPDM would be the continuous phase and PP the disperse one. The soft TPO grades with a high rubber content (30–40%) are mainly used in extrusion applications where it is possible to process the melt under continual low shear. An example is the extrusion of films with an embossed surface to create a skin for instrument panels in automotive interiors. In a special procedure, the film is treated with an electronic beam to cross-link the material, improving the wear resistance of the surface. In injection molding, a change of morphology can take place during the processing and consequently result in a loss of mechanical properties. This can be attributed to the high shear under these circumstances. Therefore, only few applications in injection molding are visible in the market, for example, the bumper of a vehicle for a good shock absorption (see Fig. 1.4). Good elasticity is not the key property requirement for this application, rather the ability to take the energy of an impact (damping or shock absorption). In the same application, TPO copolymers are used to modify PP. These TPO will be introduced separately in Chapter 4.

Fig. 1.4: Car bumper from olefinic compound with high energy absorption (source: monkeybusinessimages/iStock/Getty Images).

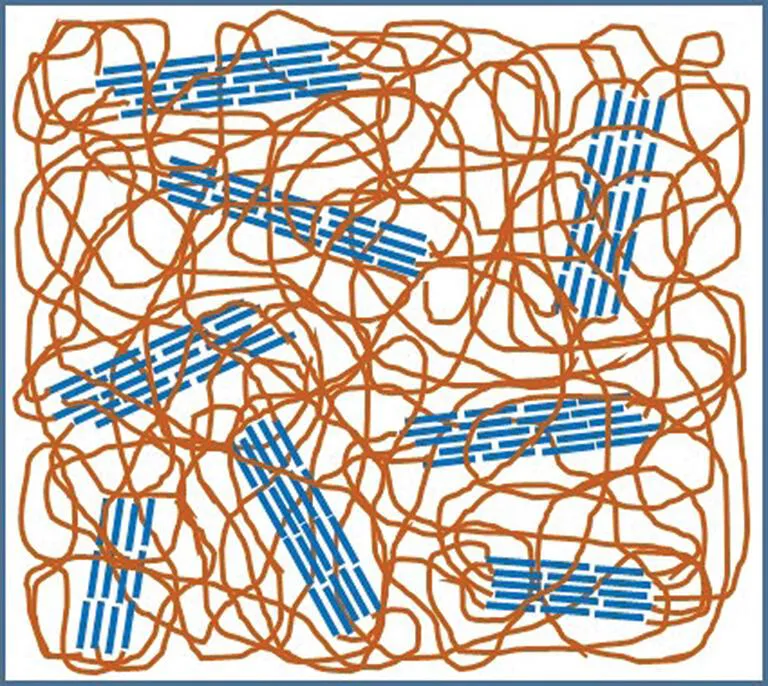

The softer the polymer mixture is, the larger the changes in morphology during processing are. In harsh processing conditions, the mobile rubber phase agglomerates, especially when the ratio is close to 50:50. The phases are in competition with one another to build the continuous one. To avoid this, the rubber particles can be chemically cross-linked during the compounding step. This is, in principle, the method to make a TPV, where the mobile soft phase is a high amount of little, discrete, and stable particles of a diameter from 1 to 10µm. During the process step in the PP melt, these elastic particles flow like a filler without any tendency of agglomeration and it is possible to include 40–80% EPDM into PP. The difference of the two morphology is illustrated in Fig. 1.5.

Fig. 1.5: Comparison of the two models of TPO blend (left) and TPV (right).

The share of rubber in the TPO compound could invite a discussion about TPE and impact-modified thermoplastics. A sharp distinction does not exist, but it is questionable how to classify the TPO compounds among the TPE family. Is the classification as a TPZ a better term because these are compounds? This will be an intensive discussion in the future and due to this uncertainty, TPO blends will not receive the same priority in the further course of this book compared to other T...

Table of contents

- Title Page

- Copyright

- Contents

- Acknowledgments

- 1 Introduction to TPE

- 2 Characteristic methods

- 3 A principal comparison of TPE to elastomers (vulcanized)

- 4 TPO – olefin-based TPE is introduced

- 5 TPV – olefin-based TPE, vulcanized, is introduced

- 6 TPS – styrene-based TPE is introduced

- 7 TPU – urethane-based TPE is introduced

- 8 TPC – ester-based TPE is introduced

- 9 TPA – amide-based TPE is introduced

- 10 Renewable materials

- 11 Description of testing procedure

- 12 Epilogue

- Index