![]()

1Fundamentals of the Casting Process

LATENT HEAT

The ‘states of matter’ are controlled by temperature and pressure, thus at room temperature (RT) and one atmosphere pressure this is known as STP – standard temperature and pressure. Almost all common metals are solids. Only a couple of the metals are liquid at RT, but this includes mercury (Hg), widely deployed in sealed glass tubes as thermometers.

Figure 4 Metal states: solid to liquid.

Adding sufficient heat to a solid body causes it to change state from solid to liquid, but requires extra heat energy at the boiling point, known as latent heat to effect this change, without temperature rise, as in Figure 4. For common solid materials, such as metals and ice, this is a reversible process as these changes of state can proceed either way, by adding or removing heat energy.

A similar process is involved to effect change from liquid to gas, but the latent heats are considerable larger. Similarly, from gas to plasma, except that this change requires extremely large quantities of heat, or electrical excitation, to reach the plasma through an ionization process, as described later.

STATES OF MATTER

The four fundamental states of matter are familiar in everyday life, although not necessarily always recognized as such.

Solids

Figure 5 The basic states of matter and phase transformations.

Figure 6 X-ray diffraction patterns – crystal and liquid.

Figure 5 shows these states as solid, liquid, gas and plasma. In fact, these all play their part, directly or indirectly, in the business of casting. Put simply, the solid state is the casting’s end product, being formed fundamentally as a structure comprising (normally) an extremely large number of minute grains formed from regular, crystallographic, arrays of the individual building blocks of molecules, as in Figure 6. These grains of highly ordered crystallographic structures possess what is known as long range order, in that each grain is (almost) perfectly composed in a regular array. The imperfections can be ignored at present, but are briefly discussed later to explain why the theoretical strength of most metals is not achieved. Nevertheless, it is self-evident that metals can be extremely strong, thereby providing the practical materials utilized in the products of the modern world, so familiar that we take them for granted. Importantly, the difference in strength and properties can, within each alloy system, be very considerably changed during the casting process.

For non-engineering castings, such as statues or many household artefacts, the mechanical properties of the casting are usually not of particular concern, and success is measured by producing a cosmetically acceptable solid structure, if sufficiently free from surface defects. However, for items that are required to withstand the rigours of engineering applications, such as those found throughout our motor vehicles, the process of casting requires considerable knowledge and understanding to provide the necessary mechanical properties. And these properties are, firstly, controlled by the casting process as the molten metal flows from furnace to mould and eventually solidifies into the final shape. This is where an understanding of the fundamentals, from fluid flow to nucleation in the solidification process, leading to a suitable microstructure, are appropriate. This sequence also determines the casting defects, entrapped or escaping from the casting, which will also determine its suitability. These aspects are reviewed later and form the difference between these modern-day castings and their predecessors in the several millennia of casting manufacture until the dawn of the ‘scientific era’. For our purposes, this was around the late nineteenth century, as the physical sciences steadily eroded the subject’s status as a ‘black art’, a consequence of a lack of understanding that included the behaviour of the four states of matter. This enabled castings to play their part in the enormous technological advances of the twentieth century. It becomes clear that the apparently simple process of casting benefits from this fundamental understanding of liquids and solidification to achieve the full potential of strong (metallic) materials. This is explored further in the next section on the control of structure.

Liquids

In contrast to solids, where in metals there exists a long-range crystallographic structure providing a settled overall shape, in a liquid this structure is no longer regularly defined. Figure 6 shows a molecular arrangement of loosely held atoms free to swim around and adopt the shape of a vessel, or disperse across a surface in the absence of containment. Thus, the familiar filling of a jug with water, that could have been produced by melting the solid (e.g. blocks of ice) with sufficient heat to reach the melting point and then overcome the latent heat of fusion.

Liquid | Density (lb/in3) | Kinematic Viscosity (in2/sec) |

Water | 36.1 | 1.6 |

Aluminium | 86.6 | 2.0 |

Cast Iron | 220.0 | 1.6 |

Steel | 254.0 | 1.4 |

Magnesium | 57.8 | 1.3 |

Copper | 288.0 | 0.6 |

Table 2 Kinmatic velocities for molten metals.

The characteristics of liquids, such as water, are relevant to the foundry worker as some molten metals have a similar fluidity to water, as seen later. In fact, cast iron has a viscosity index identical to that of water, Table 2, enabling the use of transparent models of moulds and gating systems, to observe water flow in the analysis of casting processes.

Figure 7 Surface tension: (a) the impact of a water drop, and (b) in a container.

Liquids can be regarded as incompressible fluids, comprising mobile atoms held together by intermolecular bonds that allow filling of a vessel – but retains, under gravity, a distinct free surface with an associated surface energy. Surface tension (see Figure 7) is a characteristic of the liquid, as seen from the meniscus, surface profile, made with the wall of the container. Water, for example, exhibits a distinctively different profile to mercury.

Photo 8 Matterhorn, Switzerland; showing fracture, crevasses and slow movement of glaciers down the mountain.

Photo 9 High altitude glacial movement, Tête Blanche, Swiss Alps.

Liquids have a ready facility to flow, an important feature shared with gases, used in pouring or otherwise transferring molten metal into the casting mould. The manner of this flow is understood in the study of fluid dynamics. Whilst this is a deep field of knowledge, a general grasp of its basic features enables the foundry worker to produce gating systems suitable for advanced projects. Note that whilst flow is a readily observable feature of liquids (and gases), it can also occur in solids under sufficient pressure, as seen from the effects of creep (Photos 8 and 9). In metals, such as lead piping at ambient temperatures, it can take many years; or observed as the flow of ice in the slow movement of glaciers as they progress at the stately rate of metres per year down the high mountain ranges.

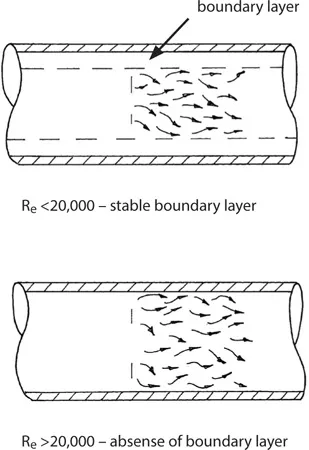

Figure 8 Turbulent flow in pipes.

Density is another important measure, as weight per unit volume (kg/m3) of...