eBook - ePub

Rubber Structures in Oil and Gas Equipment

Jie Zhang, Chuanjun Han

This is a test

Share book

- 178 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Rubber Structures in Oil and Gas Equipment

Jie Zhang, Chuanjun Han

Book details

Book preview

Table of contents

Citations

About This Book

Rubber products are widely used in all aspects of oil and gas drilling and production, which play an important role in oil and gas development. The performances of rubber products determine the safe and efficient development of oil and gas. In this book, rubber experiment and the constitutive model have been introduced. The rubber sealing ring, metal-rubber sealing structure, stator rubber of PDM, wellhead BOP and downhole rubber packer have been investigated. The mechanical properties and sealing properties of rubber structures have been studied. These contents can provide a basis for the design, manufacture and maintenance of rubber structures.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Rubber Structures in Oil and Gas Equipment an online PDF/ePUB?

Yes, you can access Rubber Structures in Oil and Gas Equipment by Jie Zhang, Chuanjun Han in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Thermodynamics. We have over one million books available in our catalogue for you to explore.

Information

1 Background

1.1 Introduction

Rubber is a highly elastic polymer material with reversible deformation, which has the characteristics of good elasticity, insulation, and impermeability to water and air. Under normal atmospheric temperature, it can be deformed by a small external force. When the external force is relieved, rubber can quickly return to its original state, and with excellent elasticity, flexibility and energy accumulation.

Rubber can be divided into natural rubber and synthetic rubber (Figure 1-1). Natural rubber is formed by coagulation, washing, molding, and drying of the sap collected directly from rubber trees. However, with the development of science and technology, natural rubber gradually cannot meet the complex requirements of civilization. Humans have begun to seek rubber with more superior performance. Thus, synthetic rubbers synthesized from various monomer materials have begun to be developed.

Synthetic rubber can be divided into general rubber and special rubber according to its use. The general rubber meets general needs, and includes styrene butadiene rubber, butadiene rubber, butyl rubber, etc. The special rubber can meet specific conditions, such as nitrile rubber, silicone rubber, fluorine rubber, etc.

1.2 Rubber used in the field of oil and gas equipment

Oil and natural gas are basic energy sources and the main pillars of national economic development. Rubber products are widely used in all aspects of oil and gas drilling and production, and play an important role in oil and gas development. The performance of rubber products determines whether oil and gas exploration can be carried out safely and efficiently. During the oil and gas development process, the service environment of the equipment is even worse. The harsh environmental conditions such as downhole high temperature, high pressure, and acidity have a great impact on the life of rubber products.

1.2.1 Rubber sealing ring

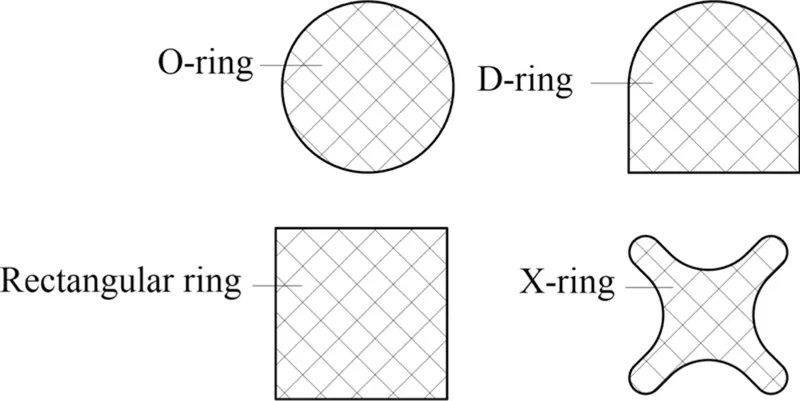

The rubber ring is a kind of squeeze type sealing ring, which relies on its elastic deformation to obtain the sealing effect, by preventing the fluid leakage. It is annular and composed of one or several parts. It’s widely used in surface equipment and downhole tools of oil and gas exploitation, as shown in Figure 1-2.

O-ring is named for its circular cross-section. The O-ring has the advantages of a simple structure and reliable sealing performance. It is widely used in various sealing structures and it is one of the most common seals used in static seals, reciprocating seals and rotary seals [1].

The O-ring can be easily twisted and worn down during installation, which reduces the cross-section of the ring. In a reciprocating dynamic seal, the O-ring is easy to twist and turn over. When the friction of the ring is uneven in the circumferential direction, the distortion is more serious. The service life of seal ring is greatly shortened due to the distortion [2, 3].

There are many seal rings with different cross-section shapes are widely used apart from the O-ring [4]. For example, the X-ring has the advantages of not rolling in the reciprocating motion, a small radial compression ratio, a lubricating cavity, limited friction resistance, and good pressure distribution on the cross section; however, it is prone to fatigue failure. The D-ring and the rectangular base can ensure that the sealing ring is properly installed, and reduce the distortion and damage of the sealing ring during the installation process [2]. In the reciprocating seal, the possibility of distortion can be reduced, and its semicircular cross-section has the advantage of self-sealing. Rectangular sealing rings are usually used for static seals. In dynamic seals, rectangular seals release heat slowly, which leads to a deterioration in the sealing performance [5].

1.2.2 Metal-rubber sealing structure in roller cone bit

A cone bit is usually used to break hard formations. It is used in the creation of deep wells, ultra-deep wells and geothermal wells, which require a higher performance and a longer life [6]. Bearing is one of the core structures of a cone bit, and bearing service life affects the service life and reliability of the cone bit [7]. The metal sealing structure in the bit can prevent the bottom hole drilling fluid from entering into the bearing, ensure the stable working environment of the bearing, and prolong its service life [8].

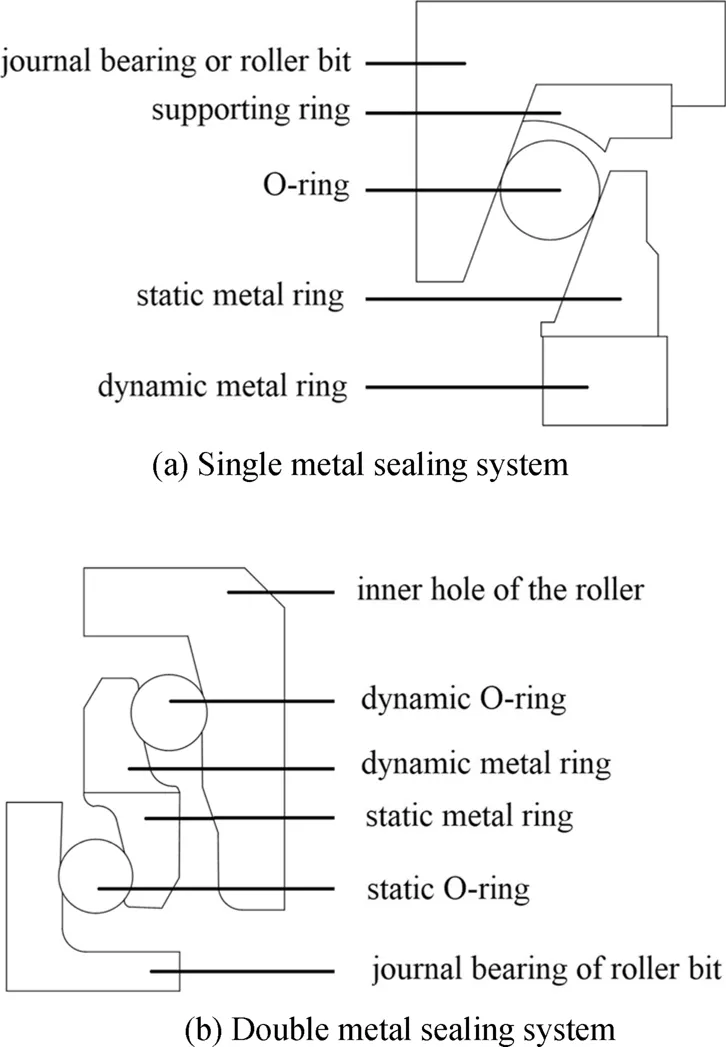

There are mainly two kinds of metal seals: single metal seal and double metal seal.

A single metal seal is composed of moving ring, static ring, O-ring, and rubber support ring. Its structure is shown in Figure 1-3. The sealing principle is that the O-ring respectively contacts with the journal and the static ring to form a static seal. Under the action of O-ring, the dynamic ring and the static ring always keep close contact, and a layer of oil film is formed between the contact surface of the dynamic ring and the static ring to realize the dynamic seal of the cone bit [9].

A bimetal seal is composed of static rubber ring, dynamic rubber ring, dynamic ring and static ring. The static rubber ring is in contact with the static ring and the bearing shaft, respectively. The moving rubber ring is in contact with the moving ring and the inner hole of the cone bit, respectively. The moving ring and the inner ring are closely bonded under the action of the two sealing rings. The moving ring and the static ring closely fit under the action of the two sealing rings, and an oil film is formed between the surfaces to ensure the sealing performance [10].

The structure of a single metal seal is simpler than that of a double metal seal, but it is easier to fail under the condition of high speed and high WOB. The metal seal structure can float to a certain extent because of the elasticity of rubber, and the metal seal has a certain anti-vibration performance. The bimetallic seal has better anti-vibration performance.

Failure of the metal seal mainly comprises the following two aspects: (1) The high temperature of the bottom hole and self-generated change the performance of lubricating oil and rubber seal ring, which reducing the failure of the sealing performance. (2) Abrasive wear and bottom hole debris in the sealing surface and the rubber ring contact ring surface, result in the wear of the dynamic ring, static ring and rubber ring.

1.2.3 Screw drill rubber lining

A screw drill is a kind of positive displacement downhole power drill, which can directly provide power for the bit at the bottom of the well. It is the most widely used downhole power tool at present. It has the advantages of low speed, large torque, large displacement and so on.

As shown in Figure 1-4. A screw drill is composed of bypass valve, motor, universal shaft and transmission shaft. The motor is the core part of screw drill [11]. The motor is mainly composed of a rotor and a stator. The rotor is a steel screw plated with corrosion-resistant material, and the stator is a steel pipe with rubber bushing on the inner wall [12]. The working principle of the screw drilling tool is that when the drilling fluid driven from one end of the motor to the other end, it drives the screw rotor to rotate in the stator and converts the liquid pressure into mechanical energy, driving the drilling tool to rotate and break the rock.

Rubber bushing is a part of the stator of screw drill, and its main material is rubber. In actual production, because of the high temperature of the bottom hole environment, friction and heat generation between stator and rotor, the rubber performance changes. The wear of the stator and rotor reduces the service life of stator. When the drilling fluid contains large solid particles, it will aggravate the wear of the stator and rotor, and even cause sand sticking fault of the drilling tool [13, 14, 15].

1.2.4 Seal structure of the pump

The mud pump is called the “heart” of the drilling circulation system. In the drilling operation, the mud pump transports a large amount of mud to the bottom of the well, which can carry out the debris and cool down the bit. Mud fluid can also be used as the power fluid in the downhole power drilling tool [16].

The piston is one of the core parts of the mud pump, which can be divided into integral piston and assembled piston (as shown in Figure 1-5). The integral piston is made of rubber vulcanized in the steel core as one whole, but the cup falls off easily during the piston movement. The cup is sleeved on the steel core in the assembled piston, and the piston is fixed by the clamp spring and the clamp plate. The structure is firm, and the interference amo...