![]()

CHAPTER VI.

CORING HOLES IN CASTINGS.

IN very many cases the best method of coring a hole is obvious and simple enough; but it is otherwise in a large number of instances. It is proposed to give in this chapter a few examples of this class of work.

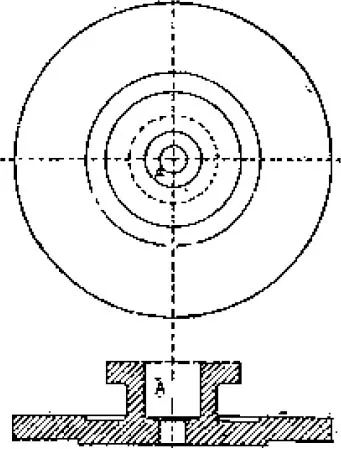

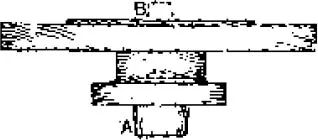

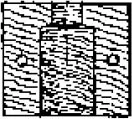

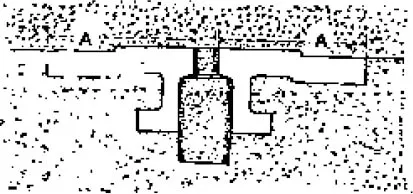

Take first one of the very simplest cases that can occur, a plain cylinder cover (shown in Figs 88 and 89). To core the centre hole A for the stuffing-box and piston-rod, a print is put on the pattern on the side which goes downwards in the mould. This is shown on the pattern at A (Fig. 90), where the pattern is illustrated in the position in which it is withdrawn from the mould. Since the hole is shouldered, that is, not parallel throughout, a core-box must be made. This is illustrated in Figs. 91 and 92. The core made from this is dropped into the print impression A in the mould, and is thus centred and retained in its correct position. The mould, with its core in place, is shown in section in Fig. 93.

Fig. 88.

Fig. 89.

Figs. 88 and 89.—Casting of Cylinder Cover.

This is a very common illustration of the simplest kind of coring. Almost all holes which pass vertically through castings are formed by the insertion of cores thus set in print impressions in the lower portion of the mould. There are a few special exceptions, as in the case of work for which the cores are so large that they are set in place by measurement alone, since they do not need assistance from the impressions of prints.

All prints which are used for vertical cores are tapered, or coned smaller in a direction away from the pattern face. This is shown in Fig. 90. It is done to prevent the print from tearing up the sand, which a parallel print would almost certainly do on withdrawal. The reason why a larger amount of taper is given to a print than to its pattern is that a moulder always desires the maximum taper which is permissible in any case. He cannot have just what he likes in a pattern, but he can in prints, and so he gets it. It is better, too, that a core print should have plenty of taper because when a print tears up the mould, the latter has to be made good again; and if badly broken, it probably would not be mended quite accurately, and then the core would be set out of truth and the hole in the casting be correspondingly out of truth. It may be noted, further, that while the print is tapered there is no taper in the core-box (Figs. 91 and 92) to correspond; consequently, taper has to be filed or rubbed on the core to make it enter and fit the print impression exactly.

Fig. 90.—Cylinder Cover Pattern.

When a few castings only are wanted, it is not usual to put the print taper in the core-box; but if many (say twenty and upwards) are required the taper should be formed in the box to correspond with that given to the print. It saves the moulder’s time, and reduces the risk of the cores being set out of the vertical, due to more being filed off one portion of the sides of the core than off others.

There is yet another point of importance. One print only is shown on this pattern (that on the bottom), and it is sufficient in the example given. But suppose the length, or height, of the core were double or treble what it is, then one print alone could not be trusted to hold safely the core upright. In such a case a second, or steady, print is put on the top face to make a hole for the top end of the core. This is shown dotted at B (Fig. 90).

Many cases occur in which top prints are absolutely necessary; but, obviously, lengths and diameters are relative. So that if a core were 4 in. diameter and 12 in. high, it could be set safely in a bottom print alone; but if it were 1 in. in diameter and 12 in. high, a top print would be required. Also, a long vertical core may be held by a bottom print alone if there is a good chance of centering it by measurement right up to the top; otherwise, a relatively short core may require a top print. For example, in Fig. 93 measurement can be taken in the mould from the edge of the core to the edge of the mould, the radius A A being easily taken. Then the question of the securing of the core in the top simply means the thrusting of the core well into its print impression, and the application of the pressure of the cope on the top of the core. Many cases, however, arise in which a large portion of the mould comes up into the top and the core has to pass up into it, and measurement cannot be taken at the top. Then a top print is desirable to guide the core correctly, because the moulder cannot see and measure it. In some later examples attention will again be drawn to this important point.

Fig. 91.

Fig. 92.

Figs. 91 and 92.—Core-box for Cylinder Cover.

Fig. 93.—Mould for Cylinder Cover.

Cases arise in which top prints cannot conveniently be used. Then the difficulty is often got over by making the bottom print double, or even treble, the usual length, so that it shall form an efficient stay, as well as a guide to the core.

The lengths of these prints and the amount of taper to be given to them vary within wide limits. For bottom p...