![]()

From Voices to Results – Voice of Customer Questions, Tools, and Analysis

![]()

From Voices to Results – Voice of Customer Questions, Tools, and Analysis

Copyright © 2018 Impackt Publishing

All rights reserved. No part of this book may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, without the prior written permission of the publisher, except in the case of brief quotations embedded in critical articles or reviews.

Every effort has been made in the preparation of this book to ensure the accuracy of the information presented. However, the information contained in this book is sold without warranty, either express or implied. Neither the author, nor Impackt Publishing, and its dealers and distributors will be held liable for any damages caused or alleged to be caused directly or indirectly by this book.

Impackt Publishing has endeavored to provide trademark information about all of the companies and products mentioned in this book by the appropriate use of capitals. However, Impackt Publishing cannot guarantee the accuracy of this information.

First published: April 2018

Production Reference: 1180418

Published by Impackt Publishing Ltd.

Livery Place

35 Livery Street

Birmingham B3 2PB, UK..

ISBN 978-1-78300-144-6

www.Impacktpub.com

![]()

![]()

Robert Coppenhaver is a product management/marketing professional and is the founder of 5P Marketing, LLC. Currently he is a consultant to Denso Wave and is responsible for the sales and marketing activities for the OEM/ODM portion of their business. Prior to 5P Marketing, Robert was a director/VP in multiple companies with P&L responsibility for over $100 million. He has worked in the fields of industrial automation, energy management, real-time software, and safety technology during his tenure with Honeywell, Rockwell Automation, Wind River (Intel), and Draeger.

During Robert's career, he has trained marketing and product management professionals in organizations such as Honeywell, TDK-Lambda, ITT, Draeger, and was adjunct faculty for Marketing at Corporate College in Cleveland, OH. He is a proponent of using Voice of the Customer to create organizational value, and has personally been responsible for over $1 billion in incremental revenue in organizations deploying VoC best practices.

Robert enjoys training others on how to use VoC to create breakthrough products and champions continuous learning of new marketing and product management strategies and techniques.

![]()

Early in my career, I was given a rather unique opportunity that would have a profound effect on not only my professional career, but my life. My employer at the time, Rockwell Automation, was trying to expand into other international markets where our market share was still very small. One such market, Japan, was in the middle of a manufacturing renaissance, as epitomized by the book The Machine That Changed the World, by James Womak. The book presented how Toyota and many other Japanese companies had embraced the teaching of Edward Deming to completely revamp their manufacturing processes. Where Japanese products and manufacturing were once regarded as junk, they were now manufacturing the highest quality and most efficient goods in the world.

My employer, Rockwell Automation, was a manufacturer of industrial automation and control equipment under the brand Allen-Bradley. Allen-Bradley had a very good reputation for quality in most of the world. Even the Allen-Bradley logo proudly exclaimed "Quality".

At Rockwell Automation, we prided ourselves on the quality of the products we produced and, recognizing the rapidly expanding market of Japan, we struggled to understand why our products did not enjoy more commercial success in the Land of the Rising Sun. During this same time period, we also entered into a partnering agreement with a company called Nippondenso.

Nippondenso was originally a part of Toyota but later became an independent company after World War II as the Supreme Command for the Allied Powers reshaped the Japanese automobile industry and Toyota was forced to spin off Nippondenso, although Toyota still maintained a sizeable minority share in the company. Nippondenso was, and still is, a large automobile parts supplier creating much of the components in a Toyota automobile. It would later expand to servicing the vast majority of automobile suppliers. While Nippondenso, now called simply Denso, was then largely an automobile parts supplier (with roughly 98% of their 2016 revenue of $40B coming from automobiles), they continued to explore other market opportunities and segments, creating divisions for robotics, data acquisition, and a division whose responsibility was to use expertise acquired from new technology in the automobile sector and apply it to OEM/ODM (Original Equipment Manufacturing/Original Design Manufacturing) markets.

It was a highly agreeable relationship between Rockwell Automation and Nippondenso. Nippondenso was looking for ways to expand their business by providing OEM/ODM design and manufacturing services and Rockwell Automation was trying to expand their product portfolio while setting up a sales channel for Japan. Rockwell Automation would contract Nippondenso to create products for the Japanese market based on the Rockwell Automation specifications, and Nippondenso would create a joint venture sales channel in Japan called AB-Denso to help sell both the newly designed products as well as the legacy Rockwell Automation products to the Japanese market. In particular, Toyota and Nippondenso's own manufacturing entities were seen as a significant opportunities.

After 3-4 years, Rockwell Automation had smaller, less expensive products produced by Nippondenso that were a better fit for the Japanese market, but still did not generate the volume of sales anticipated through the joint venture. Nippondenso explained that the new products were a great improvement over the original legacy products, but were still missing many of the features and the responsiveness exhibited by the Japanese competitors. However, the quality was not found to be unacceptable for the Japanese market. Rockwell Automation believed that they had more than enough of the key features to be successful and did not have a quality problem. They believed the issue had more to do with a lack of understanding how to apply the products in real-world applications than with any features or quality issues.

To resolve this issue, Rockwell Automation decided to send a member of their applications team to live in Japan and work with Nippondenso for three years to help train the Japanese staff and work with key customers such as Toyota on how best to use the Rockwell Automation technology in their applications. I was presented the opportunity and jumped at the chance to embark on this new adventure.

It took me very little time to realize that the Nippondenso view was the correct one. The Japanese engineers and staff, especially at Toyota and Nippondenso, were very well versed in applying automation technologies to solve real-world manufacturing challenges and they were every bit as good, if not better, than the engineers I had worked with in the USA. Rockwell Automation products were and still are considered world class with respect to quality, but were not at the same level of the Japanese competitors for the Japanese applications. Additionally, many of the features found on the Japanese-based automation products were missing from the offerings by Rockwell Automation, as they opted to focus on alternative feature sets required by other markets and customers.

My role changed multiple times during my stay in Japan as Rockwell began to realize that our products were not the global products we had believed them to be, but were really USA-centric and were designed and produced with the needs of the USA automobile market at their core.

Many in Rockwell Automation believed that the Japanese customers, and Toyota in particular, were the leading customers in the world and that if our products could satisfy their demands and applications, we could satisfy the vast majority of customer's wants and needs. Unfortunately, the will was not there to do a wholesale revamp of our products and offerings in order to be successful in Japan, so instead we offered incremental improvements, but never enough to capitalize on the larger market opportunity.

I did not realize it at the time, but I walked away with a number of methods and practices that would have a significant impact on the next phase of my career. I left Japan with an understanding of the Toyota manufacturing process, TQMS, Kaizen, competitive breakdowns, the five whys, and more. I learned how world-class customers think and make buying decisions and realized just how well customers can understand their applications and needs, but not have the ability to articulate these needs in a form that can be handed to an engineering team to develop. For that, a company needed a strong product management function to translate the customer wants and needs into product requirements that could be built.

As I rotated back to the United States, I was given the opportunity to join a team who was developing a next generation remote I/O system for Rockwell Automation. Then current remote I/O systems were either large or bulky with a lot of wasted space, or small and purpose built with little flexibility.

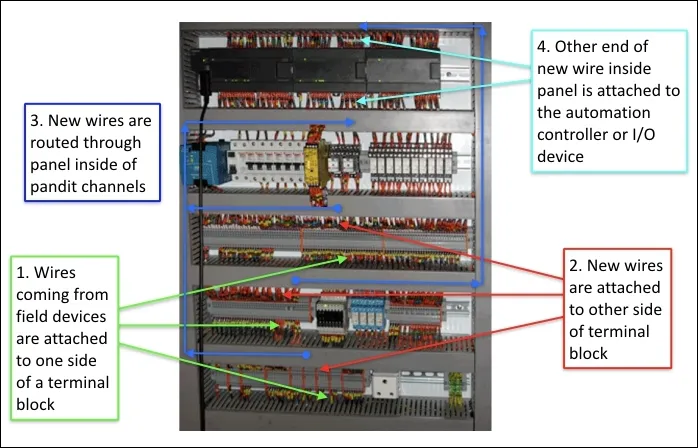

With all the offerings in the market, the customers would need to install a large number of terminal blocks to accept every wire coming from the field devices the system was controlling/monitoring. The customer would then run wires from the terminal block through the panel to the automation device, whether it was a controller or a remote I/O system. This would require a large number of terminal blocks inside every panel. Additionally, there was a large amount of wire and space inside the panel allocated to running all the wires from the terminal block to the automation device, whether it was a controller or a remote I/O system as follows:

This system resulted in extraneous costs to the customer well beyond the price of the actual automation equipment. The customer needed to buy a large amount of terminal blocks and buy a larger panel to accommodate all of them. They also needed to run a large amount of wires from the terminal blocks to the automation equipment. This resulted in additional costs for the wire and channels to run the wire and even more space inside the panel. The larger cost was the manpower to label each side of every wire, run each wire inside the panel from the terminal block to the termination on the automation equipment, and then troubleshoot each wire to ensure they were run correctly. This system also resulted in hidden costs, as many times wires were misrun or mislabeled, resulting in start-up delays. Even after the system was started up there could be more hidden costs as each wire was a point of failure, and the more wires in a system, the higher the probability that a wire would vibrate loose or create an intermittent connection.

By the time I joined the team we already had a concept in place, which was derived through another joint venture...