- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

AIChE manual updates and consolidates procedures for testing performance of distillation columns

From classic distillation operations to air stripping to other separations processes, selecting the correct column for appropriate efficient, safe, and environmentally-sound operations can be an important step. The newest updated volume in AIChE's long-running Equipment Testing Procedures series, Trayed and Packed Columns: A Guide to Performance Evaluation, Third Edition provides chemical engineers, plant managers, and other professionals with helpful advice to assess and measure performance of a variety of distillation columns, including those that utilize bubble cap, sieve, valve trays, or packing material.

The new book combines and updates into one user-friendly volume the best available field knowledge from previous publications on both types of distillation columns. Designed not as a single set of compulsory steps, but as a compilation of techniques, it will allow the user to select the procedure that best applies to its operating parameters. The testing steps presented can be used to assess reliable performance data on mass transfer efficiency, capacity, energy consumption, and pressure drop—information essential to effective troubleshooting of performance problems, identifying capacity bottlenecks, determining operating ranges, and a number of other routine maintenance and optimization processes.

Opening with an extensive definition section, organized by topical area, the book then goes on to address:

- Selection of instrumentation and identification of elements to be measured

- Pre-test planning procedures

- Strategies for data collection and evaluation, including sampling procedures

- Pre-test, in-test, and post-test considerations (equipment, safety, process, environmental)

- Computation and interpretation of results, including individual breakdowns for trayed and packed columns in terms of hydraulic and efficiency performance

- Test troubleshooting analysis in twelve key areas

The book concludes with appendices for relevant symbols and nomenclature, plus sample caculations generated from performance tests.

With its engineer-tested procedures and thorough explanations, Trayed and Packed Columns: A Guide to Performance Evaluation, Third Edition is an essential text for anyone engaged in implementing new technology in equipment design, identifying process problems, and optimizing equipment performance.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

800.0 APPENDIX

801.0 Notation

| AA | Active area of tray, (ft2, m2) |

| Adow | Cross sectional of downcomer (ft2, m2) |

| AF | Aeration factor used in estimation of sieve tray pressure drop |

| Ah | Hole area, (ft2, m2) |

| CL | Liquid capacity factor (gpm/ft2, m3/m2-hr) (Figure 15) |

| CP | Heat capacity (Btu/lb-°F, kJ/kg-°C) |

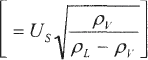

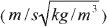

| CS | C-factor  |

| Csbf | Corrected flood C-factor (ft/s, m/s) (Figure 20) |

| D | Distillate Flowrate, (lb/hr, Kg/hr) |

| Fh | Vapor hole kinetic head,  |

| FP | Packing factor (ft−1, m1) |

| FP | Flow parameter |

| FPL | Flow path length, (in, m) |

| G | Gas mass velocity (lb/hr-ft2, kg/hr-m2) |

| GM | Molar gas mass velocity (lb mole/hr-ft2, g-mole/s-m2) |

| HETP | Height equivalent to a theoretical plate (ft, m) |

| hD | Clearance under downcomer (in., mm) |

| hD’ | Hydraulics gradient on tray, (in., mm) |

| hdry | dry head loss used in tray pressure drop calculation (in of liquid, mm of liquid) |

| hDS | Calculated clear liquid height (in., mm) |

| h’L | Head loss associated with the wet pressure drop on tray (in of liquid, mm of liquid) |

| how | Height of crest over weir (in., mm) |

| hT | Total depth of packed bed (ft, m) |

| htotal | Total tray pressure drop (in of liquid, mm of liquid) |

| HVAP | Vapor enthalpy (Btu/lb, kJ/kg) |

| hw | Weir height (in, mm) |

| HTU | Overall height of a vapor (HTUOV), liquid (HTUOL) or gas (HTUOG) phase transfer unit (ft, m) |

| K | Constant in dry tray pressure calculation |

| L | Liquid mass velocity (lb/hr-ft2, kg/hr-m2) |

| LM | Molar liquid mass velocity (lb-mole/hr-ft2, g-mole/s-m2) |

| Lw | Weir length used in pressure drop calculation (in, m) |

| m | Equilibrium line slope |

| NTP | Number of theoretical plates |

| NTU | Number of overall vapor (NTUOV), liquid (NTUOL), or gas (NTUOG) phase transfer units |

| P | Total pressure (psia, torr) |

| ΔP | Total pressure drop, (in, of H2O/ft or in. of H2O, mmHg/m or mmHg) |

| ΔPdry | Dry tray pressure drop (in. of liquid, mm Hg) |

| ΔPtotal | Total pressure drop (in. of liquid, mm Hg) |

| Q | Heat transferred (Btu/h, kW) |

| QBot | Bottoms enthalpy (BTU/hr, kJ/hr) |

| QCond | Heat removed by the condenser (BTU/hr, kJ/hr) |

| QDist | Distillate enthalpy (BTU/hr, kJ/hr) |

| QFeed | Feed enthalpy (BTU/hr, kJ/hr) |

| Qin | Energy entering distillation control volume (BTU/hr, kJ/hr) |

| QL | Volumetric liquid flow (gpm or ft3/h, m3/h or m3/s) |

| QLoss | Heat loss (BTU/hr, kJ/hr) |

| Qout | Energy leaving distillation control volume (BTU/hr, kJ/hr) |

| QReboiler | Heat supplied by the reboiler (BTU/hr, kJ/hr) |

| VReflux | Enthalpy in reflux (BTU/hr, kJ/hr) |

| QV | Volumetric vapor flowrate (ft3/hr, m3/hr) |

| Qvapor | Vapor enthalp... |

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- Acknowledgement

- List of Tables

- List of Figures

- 100.0 Purpose and Scope

- 200.0 Definition and Description of Terms

- 300.0 Test Planning

- 400.0 Methods of Measurement and Sampling

- 500.0 Test Procedure

- 600.0 Computation of Results

- 700.0 Interpretation of Results

- 800.0 Appendix

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app