![]()

CHAPTER 1

INTRODUCTION

Composite materials are the most advanced and adaptable engineering materials known to man. While composite materials in the sense used in this book—a conscious combination of two or more distinct material phases into one engineering material where the phases are still discernible—are only about five decades old, it is instructive to consider the evolution of materials and composites in a historical perspective. In school we were probably all taught that (past) civilizations are characterized by the most advanced engineering materials used at the time, e.g. stone, bronze, and iron ages, to indicate the fundamental importance of the state of engineering materials to mankind. It has always been—and to a significant degree still is—the properties of engineering materials that set the limits to man’s engineering achievements; the more capable the materials, the greater the scope for groundbreaking engineering achievements.

1.1 The Evolution of Materials

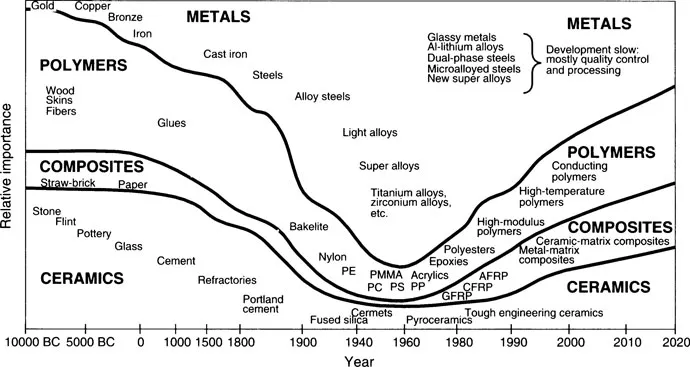

During the stone age flint, which is a ceramic, was the best cutting material known to man. Metals were of little importance, whereas natural polymers, composites, and ceramics dominated in engineering applications (houses, weapons, boats, etc.), see Figure 1-1. From then on, development of metal-working skills strongly dominated most engineering achievements well into the 20th century. In particular the position of steel has been remarkable since the middle of the 19th century. However, in the 1960s things started to change and the development in engineering materials is no longer dominated by steel and other metals, which are in relative decline worldwide. Instead polymers, composites, and ceramics are regaining their relative importance to man. The difference is that while natural polymers, composites, and ceramics dominated in the past, the current developments are due to man-made, or synthetic, materials. While these new materials, which are being developed rapidly, open up exciting and sometimes mind-boggling new opportunities, they also require new methods and capabilities in design and manufacturing [1].

Figure 1-1 Schematic of the evolution of materials used in mechanical and civil engineering applications and their relative importance to mankind. PE, PMMA, PC, PS, and PP are synthetic polymers; most of them are introduced in Chapter 2. GFRP, CFRP, and AFRP are abbreviations for glass-, carbon-, and aramid-fiber reinforced plastics, or composites, which are the subject of this book. Note that the relative importance is not in terms of tonnage or value and that the time scale is nonlinear. Redrawn from reference [1]

The preceding discussion and figure allude to naturally occurring polymers and ceramics, but there are also numerous examples of natural composites, including wood, bone, insect exoskeleton, mollusk shell, and countless others (although Figure 1-1 places wood, and probably would have placed all other natural composites, in the polymer category; it is a matter of definition). Natural composites tend to be weaker and less stiff than synthetic composites, but are often superior in terms of design and manufacture. Natural composites are also “smart materials” in that they adapt to the environment. As an example, a tree grows in such a way that it becomes stronger in the direction where strength is required and any incurred damage is gradually repaired. The composite concept is obviously not an invention.

As far as conscious human use of the composite concept goes, the earliest known example is the early Egyptians, who used straw to reinforce clay from the Nile to make brick. (There is even a biblical reference to this practice: Exodus 5:7.) In the third millennium BC, the Egyptians also made papyrus “paper” from the papyrus reed by placing strands of the reed parallel to each other to form layers, which then were stacked perpendicular to each other in alternate directions; the stack was then allowed to dry under pressure to form the paper-like sheet. Also the Chinese used straw-reinforced brick and in 108 AD invented paper (the word paper is, incidentally, derived from the word papyrus), which is a random, planar arrangement of individual cellulose fibers held together by a binder. Although predominantly known as Chinese and Japanese art forms, the invention of metal-wire reinforcing of ceramics has also been attributed to the Egyptians [2].

In the preceding paragraphs the noun composite (which is derived from the Latin verb componere, meaning to put together) has been used in a very generous sense. Moreover, in contemporary language, composite is used in several other contexts than that of this book. The meaning used herein is well established in engineering terminology and refers to a combination of two or more distinct materials into one with the intent of suppressing undesirable properties of the constituent materials in favor of the desirable properties. This definition obviously does not include metal alloys or polymer blends, which are material combinations on the atomic level. The key feature of a composite is that it offers a combination of properties that are not available in any isotropic material; composites are an entirely new and unique material family.

1.2 The Composite Concept

In load-bearing, or structural, applications, composites in most cases comprise a bulk phase enclosing a fibrous reinforcing phase; in conventional terminology one talks of matrix and reinforcement. The objective of the matrix is to integrally bind the reinforcement together so as to effectively introduce external loads to the reinforcement and to protect it from adverse environmental effects. While the matrix gives a composite its shape, surface appearance, environmental tolerance (to high temperature, water, ultra-violet light, etc.), and overall durability, it is the fibrous reinforcement that carries most of the structural loads and thus largely dictates macroscopic stiffness and strength.

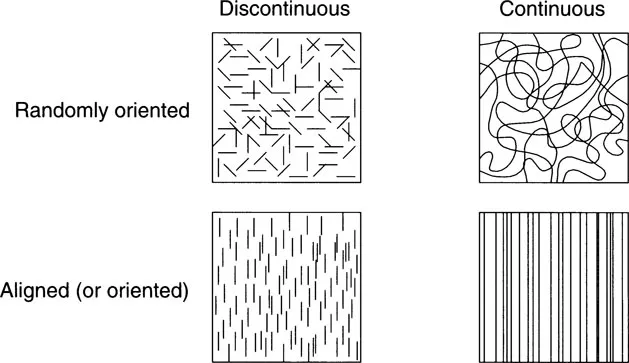

Although numerous examples of the composite concept may be distinguished in everyday life, including paper, Kraft paper, particle (chip) board, and reinforced concrete to mention just a few, the most specialized incarnations are those that are the main subject of this book. Practically all successful structural composites have man-made constituents. The matrix may be metallic, ceramic, or polymeric in origin. While metal and to some degree ceramic matrices are used in structural composite applications, polymer matrices are currently by far the most significant matrix category and this book therefore concentrates on polymer composites. There are two main polymer families; thermosets and thermoplastics. The vast majority of current composite applications utilize thermosets, which solidify through a chemical reaction called crosslinking or cure. Thermoplastics differ in that they can be melted and therefore solidify through cooling of the melt without any chemical reaction taking place. In polymer-matrix composites, the common reinforcement types are (in order of decreasing importance) glass, carbon, and polymer. The composite reinforcement may be discontinuous (“short fibers”) or continuous (“endless fibers”) and randomly oriented or aligned, see Figure 1-2.

Figure 1-2 Schematic of different reinforcement configurations

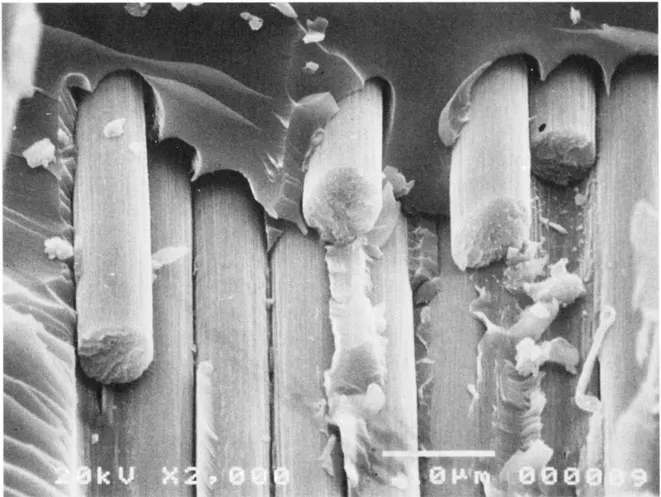

Since the reinforcement is the primary load-bearing constituent, its configuration (form and degree of orientation in the matrix) is critical to the macroscopic properties of the composite. It should therefore come as no surprise that the most impressive mechanical properties are found in composites with continuous and aligned reinforcement, see Figure 1-3. While clearly structurally inferior, composites with randomly oriented reinforcement are common in both structural and semi-structural applications; whether the reinforcement in such composites is discontinuous or continuous is of secondary importance from a structural point of view. In many applications, different reinforcement configurations are mixed within one and the same component.

Figure 1-3 Fracture surface of continuous carbon-fiber reinforced epoxy composite. The fiber diameter is 7 μm. Photograph courtesy of Jakob Kuttenkeuler, Department of Aeronautics, Royal Institute of Technology, Sweden

Probably the most common reason why polymer composites are used in structural applications is that they offer a given property, often stiffness, at a lower weight than the competition, which most of the time is a metal, but sometimes also plastic, wood, or concrete. One therefore talks of excellent specific stiffness and strength, i.e. property normalized with (divided by) density. There are numerous potential advantages of composites other than their excellent structural capabilities, including corrosion resistance, electrical insulation, reductions in tooling and assembly costs, and many more. These advantages, illustrated with a number of application examples, are further discussed in Section 1.5. It is, however, important to realize that these potential advantages assume that appropriate constituents are chosen, since if inappropriate constituents are chosen, the result instead may be that the composite alternative turns out to be vastly inferior.

While it is easy to become impressed with the potential advantages of composites, the disadvantages must not be ignored. It is probably essentially true that if one disregards cost, a polymer composite can outperform any other engineering material in all respects except temperature tolerance. It is nevertheless rare that cost is not important, thus one also has to take into account less desirable traits of composites, such as high raw material cost, lack of knowledge and experience, and difficult manufacturing. Composites are therefore certainly not appropriate in all applications; a critical assessment of the material alternatives must always be made in terms of performance-to-cost ratio. It is highly unlikely that decreases in raw material cost due to increasing production volumes alone will make composites directly cost-competitive with other materials in any wide range of applications, but in terms of knowledge, experience, and manufacturing matters can be significantly improved to further enhance the competitiveness of composites.

1.3 Design and Manufacturing

Almost all designers have been educated on and still only work with materials that are essentially isotropic, e.g. metals, and only the odd one has any real knowledge and experience of composites, which quickly make the design task vastly more difficult due to the inherent anisotropy of the materia...