Offsite Architecture

Constructing the future

Ryan E. Smith, John D. Quale, Ryan E. Smith, John D. Quale

- 282 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

Offsite Architecture

Constructing the future

Ryan E. Smith, John D. Quale, Ryan E. Smith, John D. Quale

Información del libro

Architects have been intrigued by prefabricated construction since the early twentieth century. Recent advances in design, engineering and manufacturing processes have led to a significant expansion in the use of pre-assembled components, which are fitted to finished structures on site. Collectively, such processes are becoming known as "offsite construction."

A ground-breaking text, Offsite Architecture establishes the current – and future – state of thinking in this field. A range of the most highly regarded thinkers and practitioners from around the globe share their ideas and practical findings on offsite prefabrication, examining theory and practice, opportunities and challenges, successes and failures.

A timely response to the growing interest in this method, the book provides the fundamental basis for a critical, reflective approach to offsite architecture. Contributions from both academics and professionals make Offsite Architecture required reading for practitioners as well as students taking courses in architecture, prefabrication, construction and engineering.

Preguntas frecuentes

Información

Part B

Offsite practices

Chapter 6

Offsite construction industry meta-analysis

Introduction

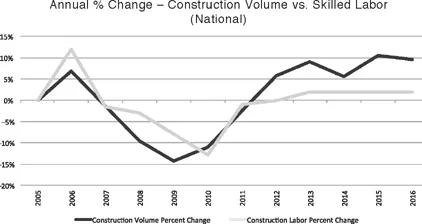

Demand of construction versus supply of skilled labor, 2005–2016 (Credit: Cumming Corporation)

Surveys

Prefabrication and Modularization: Increasing Productivity in the Construction Industry (2011) McGraw-Hill Construction

Intent

Method

Key findings

Key findings from the 2011 McGraw-Hill Construction report

| Schedule | 66% reported that project schedules are decreased. 35% responded that the reduction is by four weeks or more. |

| Cost | 65% reported that project budgets are decreased. 41% responded that the reduction is by 6% savings or more. |

| Waste | 77% reported that construction site waste is decreased. 44% responded that the reduction is by 5% or more. |

| Usage | 63% of those that responded have been using prefabrication methods for five years or more. 85% of respondents are using prefabrication today (90% of engineers, 84% of contractors, and 76% of architects). |

| Only 37% have been using prefabrication at a high or very high level (more than 50% of projects). | |

| Within the building, respondents indicated that prefabrication most often occurs in the building superstructure (27%), MEP systems (21%), and exterior walls (20%). | |

| To use prefabrication methods, the following are parameters for consideration: job site accessibility (58%), number of building stories (53%), type of exterior (52%). | |

| Prefabrication is used in 47% of small construction firms, in 28% of medium-sized firms, and in 25% of large firms. | |

| Prefabrication is used by 22% of small A/E firms, 32% of medium firms, and 46% of large firms. | |

| Barriers | The primary reason that the respondents indicated why they are not utilizing prefabrication methods on some or all of their projects is that the architect did not design them into their projects. (Architects claim that the resistance is from the owners.) |

| Drivers | The current drivers for utilizing prefabrication methods are as follows: 77% to improve productivity; 66% as a competitive advantage; 51% because it generates greater return on investment; 39% because of owner/client demand. |

| 34% of respondents indicated that using prefabrication leads to improved site safety, while 56% of respondents indicated that prefabrication is just as safe. | |

| Markets served | The five sectors using prefabrication in over 40% of projects are: healthcare (49%), higher education (42%), manufacturing (42%), low-rise office (40%), and public (40%). |

Prefabrication and Modularization in Construction 2013 Survey Results (2013) FMI

Intent

Method

Key findings

| Usage | 48% of MEP contractors accomplished m... |