eBook - ePub

Handbook of Semiconductor Electrodeposition

R.K. Pandey, S.N. Sahu, S. Chandra

This is a test

Compartir libro

- 304 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Handbook of Semiconductor Electrodeposition

R.K. Pandey, S.N. Sahu, S. Chandra

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Aiming to bridge the gap in understanding between professional electrochemists and hard-core semiconductor physicists and material scientists, this book examines the science and technology of semiconductor electrode-positioning. Summarizing state-of-the-art information concerning a wide variety of semiconductors, it reviews fundamental electrodeposition concepts and terminology.

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Handbook of Semiconductor Electrodeposition un PDF/ePUB en línea?

Sí, puedes acceder a Handbook of Semiconductor Electrodeposition de R.K. Pandey, S.N. Sahu, S. Chandra en formato PDF o ePUB, así como a otros libros populares de Technologie et ingénierie y Ingénierie de l'électricité et des télécommunications. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Edición

1Categoría

Technologie et ingénierie1

Basic Concepts

Thin-film technology is the basis of astounding developments in solid-state electronics. The thin films can be obtained either by physical methods (e.g., thermal evaporation, sputtering, epitaxial growth) or by chemical methods (e.g., anodization, chemical vapor deposition (CVD), chemical bath, electrodeposition). Physical methods are expensive but give relatively more reliable and more reproducible results. Most of the chemical methods are cost-effective, but their full potential for obtaining device quality films has not been fully explored in many cases. Electroplating is the simplest of the chemical methods, and it is rather surprising that efforts to obtain good quality semiconductor films have only recently started.

The art of electroplating metals and metallic alloys has been in vogue for nearly a century, and the earlier efforts are well documented (Brenner 1963a,b; Bockris and Damjanovic 1964; Fleischman and Thirsk 1963; Lowenheim 1974; Duffy 1981; Blum and Hogaboom 1949). Most of the development has been more by way of art rather than science, which started to emerge only recently. Further, the viability of using the electrodeposition technique as a tool of materials technology is attracting attention as a means of obtaining films of a wide variety of materials including semiconductors, high-Tc superconductors, polymer films, materials for functional biostimulation (Ir2O3, Rb2O3, RuO2, etc.), specific electronic device application materials, and others.

Some of the key advantages of the electrodeposition technique are

- It is possible to grow uniform films over large areas, as well as irregularly shaped surfaces.

- Compositionally modulated structures or nonequilibrium alloys can be electroplated.

- A wide range of industrial experience can be drawn upon.

- It is specially attractive in terms of cost, high throughput, and scalability.

This monograph seeks to introduce the state of the art of electrodepositing elemental and compound semiconductor films, which is a development of the last two decades. Broadly speaking, the electrodeposition process encompasses physical as well as chemical phenomena that require an understanding of the following aspects:

- The influence of electric fields and ionic transport on the discharge process.

- Thermodynamic and kinetic factors related to the electrodeposition process.

- Factors controlling composition, structure, and morphology.

- The role of additives during electrodeposition. What happens to them?

- The use of in situ and ex situ probes for the characterization of electrodeposits.

- What control schemes can be envisaged that will result in deposit properties that satisfy the standards set by the photovoltaic, electronic, and other industries?

I Basics of Electrodeposition

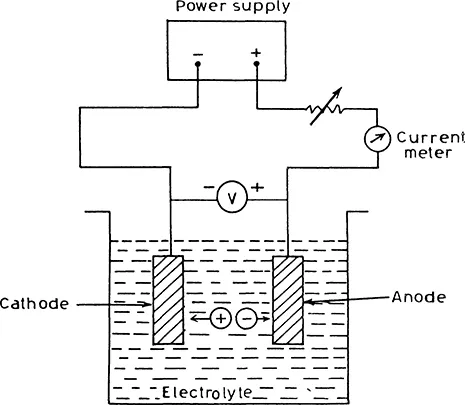

Electrodeposition of metallic films (commonly known as electroplating) has long been known and used for preparing metallic mirrors and corrosion-resistant surfaces, among other things. In its simplest form, the electroplating or electrodeposition bath consists of an electrolyte containing metal ions (for example, CuS04 solution for the deposition of copper), an electrode or substrate on which the deposition is desired, and a counter electrode. When a current flows through the electrolyte, the cations and anions move toward the cathode and anode, respectively, and may deposit on the electrodes after undergoing a charge transfer reaction. Suppose copper is to be electrodeposited. Then the electrodeposition bath could contain some Cu salt such as copper sulfate as shown in Fig. 1.1. The Cu2+ ions deposit on the substrate, and a copper coating is obtained. Historically, the discovery of electroplating can be traced back to Michael Faraday and his famous laws of electrolysis. Faraday’s laws can be stated as follows.

Faraday’s First Law. The total amount of chemical change produced by an electric current is proportional to the total charge passing through the electrolyte.

Figure 1.1 Schematic representation of a simple electrodeposition bath.

Faraday’s Second Law. The masses of the different substances liberated in the el...