eBook - ePub

Cellular Manufacturing

One-Piece Flow for Workteams

ProductivityDevelopmentTeam

This is a test

Compartir libro

- 86 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Cellular Manufacturing

One-Piece Flow for Workteams

ProductivityDevelopmentTeam

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Cellular Manufacturing: One-Piece Flow for Workteams introduces production teams to basic cellular manufacturing and teamwork concepts and orients them for participating in the design of a new production cell. Use this book to get everyone on board to reduce lead time, work-in-process inventory, and other profit-draining wastes. Each chapter includes an overview and a summary to reinforce concepts, as well as reflection questions, which can be used to encourage group discussions. This volume is part of Productivity Press' Shopfloor Series, which offers a simple, cost-effective approach for building basic knowledge about key manufacturing improvement topics

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Cellular Manufacturing un PDF/ePUB en línea?

Sí, puedes acceder a Cellular Manufacturing de ProductivityDevelopmentTeam en formato PDF o ePUB, así como a otros libros populares de Business y Operations. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Chapter 1

An Introduction to Cellular Manufacturing

CHAPTER OVERVIEW

What Is Cellular Manufacturing?

One-Piece Flow

High-Variety Production

Understanding Processes and Operations

Processes

Operations

Benefits of Cellular Manufacturing

How It Helps Companies

How It Helps You

In Conclusion

Summary

Reflections

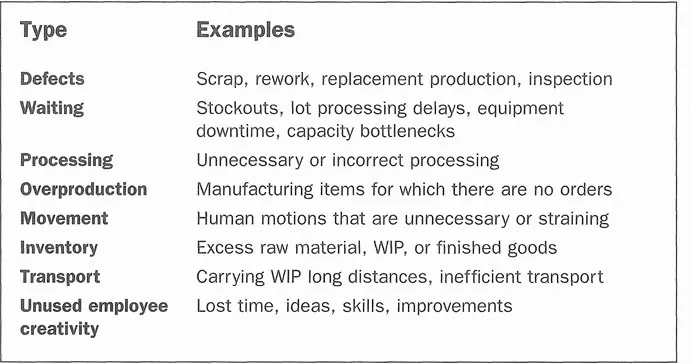

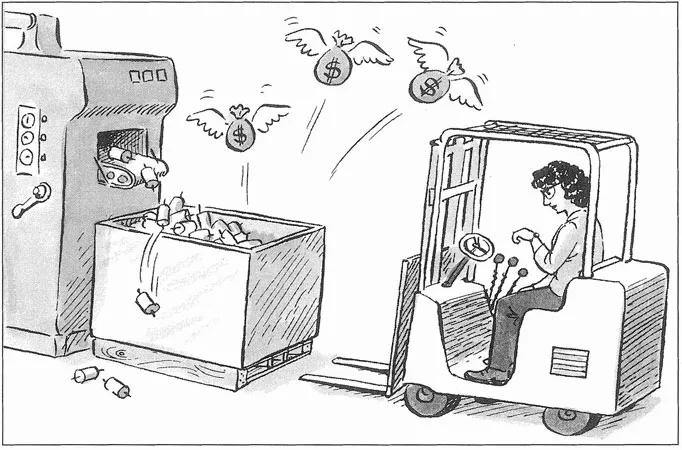

Figure 1-1. Waste in Manufacturing

What Is Cellular Manufacturing?

Cellular manufacturing is a lean manufacturing approach that helps companies build a variety of products for their customers with as little waste as possible. In cellular manufacturing, equipment and workstations are arranged in a sequence that supports a smooth flow of materials and components through the process, with minimal transport or delay.

Cellular manufacturing is a major building block of lean manufacturing. Lean manufacturing is an approach for building the variety of products customers require, profitably. Lean manufacturing makes companies more profitable and competitive by reducing wastes that typically add cost and lead time to the manufacturing process. Waste in this sense means any element of the manufacturing process that adds cost without adding value to the product. Figure 1-1 lists eight types of waste addressed by a lean manufacturing system.

Cellular manufacturing gets its name from the word cell. A manufacturing cell consists of the people and the machines or workstations required for performing the steps in a process or process segment, with the machines arranged in the processing sequence. For example, if the process for a particular product requires cutting, followed by drilling and finishing, the cell would include the equipment for performing those steps, arranged in that order.

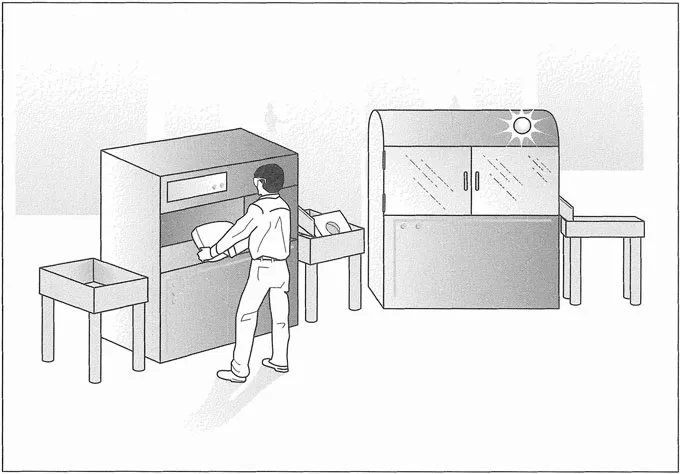

Figure 1-2. Loading a Machine with One Piece of WIP

Arranging people and equipment into manufacturing cells helps companies achieve two important goals of lean manufacturing—one-piece flow and high-variety production.

One-Piece Flow

One-piece flow is the state that exists when products move through a manufacturing process one unit at a time, at a rate determined by the needs of the customer (see Figure 1-2).

The opposite of one-piece flow is large-lot production. Although many companies produce goods in large lots or batches, that approach to production builds delays into the process. No items can move on to the next process until all the items in the lot have been processed. The larger the lot, the longer the items sit and wait between processes.

Figure 1-3. Large-Lot production Creates Waste

Large-lot production can lower a company’s profitability in several ways (see Figure 1-3).

• It lengthens the lead time between the customer’s order and delivery of the products.

• It requires labor, energy, and space to store and transport the products.

• It increases the chances of product damage or deterioration.

In contrast, one-piece flow production solves these problems.

• It allows the company to deliver a flow of products to customers with less delay.

• It reduces the resources required for storage and transport.

• It lowers the risk of damage, deterioration, or obsolescence.

• It exposes other problems so they can be addressed.

One-piece flow is an ideal state; in daily operation, it is not always possible or desirable to process items just one at a time. The important thing is to promote a continuous flow of products, with the least amount of delay and waiting. Cellular manufacturing helps by focusing on the material going through the process, not just on the equipment for each operation.

High-Variety Production

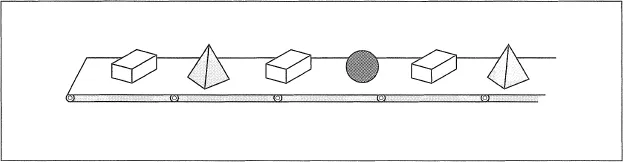

Figure 1-4. High-Variety Production

In the early days of industry, a company could produce one type of product and customers would buy it, even if it wasn’t exactly what they would have liked. Today, however, customers expect variety and even customization, as well as specific quantities delivered at a specific time. If your company isn’t flexible enough to serve their needs, they will go to your competitor.

Cellular manufacturing offers companies the flexibility to give customers the variety they want (see Figure 1-4). It does this by grouping similar products into families that can be processed on the same equipment in the same sequence. It also encourages companies to shorten the time required for changeover between products. This eliminates a major reason for making products in large lots–that changeovers take too long to change the product type frequently.

TAKE FIVE

Take five minutes to think about these questions and to write down your answers:

• What is the size of a typical processing...