1.1.1 Development Over the Past 25–30 Years

The market for PET bottles has seen a dramatic growth over the past 25 years. According to figures of DeWitt & Company Incorporated, worldwide PET consumption for bottle production was only 970,000 tons in 1988 and has increased to a staggering 13,954,000 tons that was estimated for 2011. With this growth, the market and economic conditions affecting bottle production have also changed dramatically.

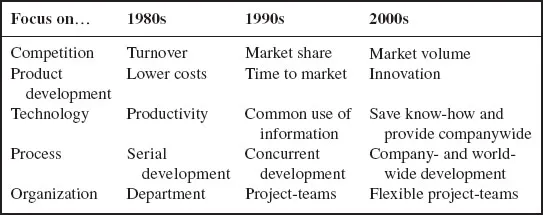

Although driving down costs was a central theme in product development in the 1980s, that focus has shifted to innovation. It is no longer enough to keep costs down and shorten time to market. Today, the ability to innovate has become vital.

Furthermore, the processes within product development have changed significantly, in particular, in countries with higher price levels. What started as a serial development, i.e., the sequential processing of tasks, became parallel or concurrent processing of individual steps in the 1990s, and is now characterized by the utilization of a company’s total resources for a single project, sometimes even on a global scale.

With regard to organization, the 1980s were dominated by departmental thinking. The 1990s saw the introduction of project groups that have since become highly flexible teams as a result of the ever-increasing requirements of product development. For each project, the right people are brought together from the available resources to achieve the best results and keep the time to market as short as possible. Ideally (and in some large companies this has already become a reality) the employees no longer have their own desks but rolling workstations, which can be moved together for flexible project work.

The big challenge today lies in making the technological knowledge – which in most cases is still locked up in the brains of the more experienced staff – available to the entire company and securing its availability to the company for the future. State-of-the-art CAD systems in conjunction with databases now permit such an advanced knowledge management.

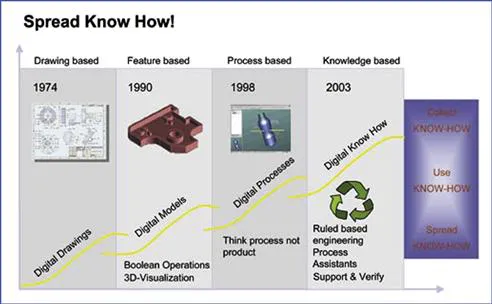

Figure 1.1 Development of know-how: Since the development of the first digital drawing the industry has evolved to an ever more sophisticated design process.

(Picture courtesy of Krones AG).

The figure above illustrates how documentation and use of the accumulated knowledge developed over time. About 30 years ago, the first digital 2D drawings still left a great deal of scope for interpretation, especially with respect to design elements that were complex and difficult, or even impossible, to describe in geometrical terms. The 1990s saw the introduction of 3D systems that were able to display free-form surfaces and design elements of sophisticated containers. This kind of visualization was still somewhat feature oriented, but around the turn of the millennium, larger companies started using digital processes. Unlike mere mold makers, such companies – in a manner similar to machinery and systems suppliers that offer a comprehensive mold service – have adopted a process approach, which also means that questions of transport or filling are already addressed during the development phase. This comprehensive approach can best be described by the maxim “Think process – not product.” Today, rule-based computer systems and software packages are used, which make it possible to examine, verify, and benchmark the required container at a very early stage. For example, modification of the shoulder part of a bottle can be analyzed and evaluated in different variants to establish the best solution as a benchmark.

Such knowledge-based systems enable organizations to maintain the accumulated expertise and make it accessible to all employees, irrespective of their geographical location. This is the only way short development times can be achieved in a cost-efficient manner. It should be noted, however, that only high-end systems such as Unigraphics NX permit such a style of working and offer an efficient support in the day-to-day work.

1.1.2 Starting Point of a Product Development

Experience has shown that 80% of the costs for developing a product are determined at a very early stage in the design phase. Even before the first stroke of the pen or the first click of the mouse in the CAD system, a number of issues must have been settled to permit an efficient and speedy development of a product design in cooperation with the customer. In this respect, the sequence in which the questions are addressed is not critical and may differ with each specific project.

1.1.2.1 Product Life Cycle

One of the first things to determine is the intended product life cycle. Will it be a premium product with a very long useful life? A mineral water bottle for the catering trade, for example, which is placed on the table by the waiter, must have a high-quality design that stands the test of time as well as being physically robust. Premium products also serve to enhance the identification with the brand. Global carbonated soft drink (CSD) suppliers sell their products in bottles with a characteristic design, which are good examples of long-life products.

Figure 1.2 High-quality water bottles: Shelf life must be designed into the product at an early stage.

(Picture courtesy of Krones AG).

At the other end of the range, there are low-cost bottles for six packs, discount chains, or seasonal products that may only be offered for a single summer. Such seasonal products can be found in Asia, for example, where certain types of tea are sold in bottles that are specifically designed for each harvesting season. This of course results in very short life cycles for the container designed.

In this context the question of whether the bottle is intended to be returnable or nonreturnable will be answered.

Figure 1.3 Tea bottles: Some bottle brands are on the shelf for only a short period of time.

(Picture courtesy of Krones AG).

1.1.2.2 Competitors

Identification of competitors and the specific products with which the ne...