eBook - ePub

Introduction to Industrial Automation

Stamatios Manesis, George Nikolakopoulos

This is a test

Compartir libro

- 441 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Introduction to Industrial Automation

Stamatios Manesis, George Nikolakopoulos

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

This book provides an extended overview and fundamental knowledge in industrial automation, while building the necessary knowledge level for further specialization in advanced concepts of industrial automation. It covers a number of central concepts of industrial automation, such as basic automation elements, hardware components for automation and process control, the latch principle, industrial automation synthesis, logical design for automation, electropneumatic automation, industrial networks, basic programming in PLC, and PID in the industry.

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Introduction to Industrial Automation un PDF/ePUB en línea?

Sí, puedes acceder a Introduction to Industrial Automation de Stamatios Manesis, George Nikolakopoulos en formato PDF o ePUB, así como a otros libros populares de Computer Science y Information Technology. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

1Industrial Automation

1.1The Industrial Control System

Every industrial production process consists of a series of simple or complicated machines that, through the combination of raw materials, undergo a sequential transformation and integration in order to produce a final product. The term “machine” denotes every kind of electromechanical device on the industrial floor, e.g., from a simple motor (such as a drilling or a cutting machine) up to a complicated chemical machine (e.g., a chemical combustion machine). The whole set of machines (namely non-homogeneous machines), which are being integrated and combined in an industrial production process, will be referred to as an “integrated machine”.

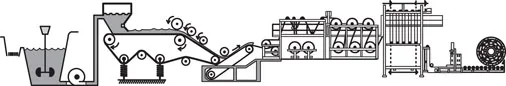

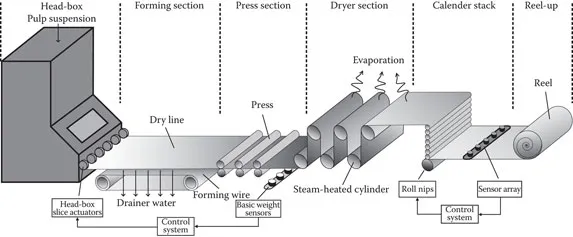

As an example of an integrated machine, Figure 1.1 depicts the typical production line of an integrated paper machine, where the initial raw pulp is undergoing the sequential processes of pretreatment and grinding, refining, pulp bleaching, and pulp pressing and drying, until it is transformed into the final paper of predefined quality. Figure 1.2 shows the various stages of the papermaking process. During the pretreatment and grinding, in the first stage of the papermaking process, debarked and washed wood logs are preheated in order to become easier to grind and are inserted into large wood log grinders, which produce wood chips. Refining is the second stage of the paper manufacturing process, when the quality of the final product is highly dependent on that specific subprocess. During that stage, the wood chips are being received and transformed into pulp via high energy consumption, water infusion, and addition of chemical compounds. During the next stage of pulp bleaching, the pulp produced by the refining system is fed to the machine that is responsible for the discoloration of the mixture. Bleaching is a chemical process applied to cellulosic materials in order to increase their brightness. The last stage of the paper manufacturing process is the drying and pressing process. During this stage, bleached pulp is dried and pressed in order to form the desired production paper.

Figure 1.1Schematic of a pulp and paper industrial process.

Figure 1.2Simplified visualization of the pulp processing stages.

In the case of an integrated machine, the whole sequence of operations for all the involved machines, the exact transformations and integrations of the raw materials, as well as the overall operational requirements, are a priori detailed and clearly defined for the industrial automation engineer, who is in charge of designing and implementing the desired process automation. For a specific production line, the sequence of operations and transformations, applied to the products, are generated from the production process itself and it is not possible, due to simplifications, these process stages to be altered. For example, in the case of an integrated machine of producing biscuits, it has been already defined from the process of production (the total manual and human-based processes) that in the mixture chamber, first the milk should be inserted and in a certain quantity, while in the sequence, the flour should be inserted at specific feeding rates and quantities. In this example, it is not possible, in order to simplify the overall automation process, to override this procedure by either designing an automation system that will either inverse the previous sequence of operations (e.g., first the flour will be inserted and then the milk) or completely ignore the predescribed sequence by allowing both materials to be inserted at the same time in the mixture chamber. Overall, and for all the produced industrial automations, the automated procedure should always satisfy the rules and sequences of the manual produced product, independently of the related complexity in the automation solution.

From the beginning of the industrial era, the main aim of every production process was the achievement of a higher possible level of automation. Reducing the number of personnel involved was also a common aim from the factory owners, as well as the machine suppliers, in order to follow the significantly increasing trend in automation, while the overall development of the industrial processes has taken place in parallel with the technological breakthroughs at the beginning of the nineteenth century and especially when human labor began to be replaced by machines. The transition of the production model, from the initially multi-interrupted form to the continuous form, required the development of specific methodologies and tools that would allow the central coordination of all the various procedures with minimal human intervention in the overall process.

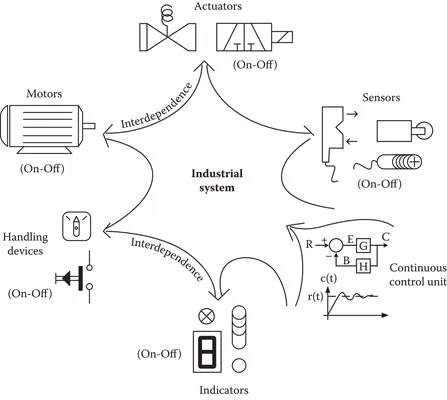

Before analyzing the procedures needed for automating an industrial production line, it is of paramount importance to initially define in detail the various components that the automation and their specific functionalities and properties consist of. In an industrial production line, the “movement” is the fundamental and generalized characteristic of the overall process, since it is impossible to consider an industrial process without the existence of a linear, circular, or any other form of movement. Even in the case of a chemical reaction, where the existence of motion is not obvious, the movement also exists in this case and more specifically in the form of an electrovalve control, which opens in order to supply the reactor with the necessary amount of the reacted components. Furthermore, the existence of the need for movement is significantly evident, either in the cases where the product should be transferred to the various process points of the production line, or in the cases of integrated machines, where parts of the machines should be moved in order to produce the desired processing of the developing product. The machines that can be utilized for the creation of the movement can be categorized into two large categories, as displayed in Figure 1.3.

Figure 1.3Basic kinds of industrial-type equipment composing an “industrial system”.

The first category includes the different types of motors, independently of the operating principle (e.g., one-phase motors, three-phase motors, motors with short-circuit rotors, motors with direct start, motors that start in a Y/Δ mode, etc.) that creates a primary rotational movement, which can be further transformed by the utilization of appropriate mechanisms in a linear or other type of movements. The second category includes all the actuators, where a linear movement is created as the result of the attraction generated by an electromagnet (coil) on a ferromagnetic core, such as the various forms of electro-vanes, electrovalves, etc. The common characteristic of motors and actuators is the fact that they have only two possible states of operation. For expressing these states, usually we refer to them as “the motor is in operation”, “the motor is not operating”, “the electrovalve is energized”, “the electrovalve is not energized”, “the coil is under voltage”, and “the coil is not under voltage”. In general, there are two states of operation that can be defined as the ON and the OFF operation, which can be further associated directly with the digital logic symbols of 1 and 0.

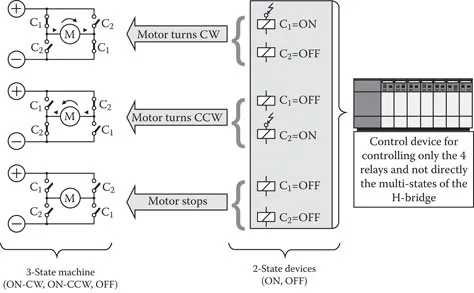

If one motor has, for example, two rotation directions or two rotational speeds and thus two states of operation, ON1 and ON2, then this consideration is not in conflict with the previous association. Actually, it can be considered as the case of having two motors, where one motor has the two states OFF-ON1 and the other one has the states OFF-ON2. The operation of the two motors, and more specifically the supply of the motors with the required electrical power, is achieved by the power relays that also have two states of operation, the ON and the OFF state. The control of the motors is achieved through the proper control of the relays, and thus the desired control system is applied on the corresponding relays controlling the electrical supply to the motors and it is not applied directly on the motors.

After the definition of the control action being applied directly on the relays, the previous situation with the existence of multiple ON states for a machine will be explained more, through the following example. A three-phase motor is being considered with two directions of rotation. For the operation of the motor, two power relays are needed, which will be denoted by C1 and C2, as shown in Figure 1.4. When the C1 relay is energized (relay C2 is not energized), the motor’s coil ends are connected to the phases R, S, and T of the power network and thus the motor has a certain direction of rotation. When the power relay C2 is energized (relay C1 is not energized), the same motor’s coil ends are connected to the phases T, S, and R of the power network and thus the motor has the opposite direction of rotation. As has been explained before, due to the fact that the control system is being applied on the power relays, the two states ON1 and ON2, of the same motor, correspond to the states of ON and OFF of two different devices, which are the power relays C1 and C2. As a result, the control system, instead of the states OFF-ON1-ON2 of a motor, with two directions of rotation, is being equivalently applied on the OFF-ON states of two different power relays.

Figure 1.4Multi-state electric motors are controlled by two state power relays.

To control the operation of an integrated machine, a set of specific operation control devices needs to be incorporated in the overall automation, like a simple push button, a rotational selector switch (knob), etc. In the case that the operation of the integrated machine is set in the “manual” mode, the operator is utilizing the operation devices for turning on the desired motors or the actuators and in the proper...