![]()

1 / Before the War

German-U.S. Trade in Chemicals

To understand the prewar economy in synthetic organic chemicals, consider a typical, if imaginary, journey of a synthetic dye and a synthetic pharmaceutical from Germany to the United States in 1914. On the eve of World War I, indanthrene blue GCD and Salvarsan represented the most advanced synthetic organic dye and pharmaceutical yet produced by the German industry. Americans had embraced both upon their introductions to the world markets, and the two products illustrate the complex global networks—technological, commercial, and political—underlying this high technology industry of the late 1800s and early 1900s.

More than earlier classes of dyes, the indanthrene dyes of Badische Anilin & Soda Fabrik (BASF) held fast to the fabrics, whether subjected to light, repeated washings, or other threats to a dye’s integrity. Chemist René Bohn had discovered the first of indanthrene dyes in 1901 while searching for new compounds that would mimic the properties of indigo, the most important natural dye over the ages and one recently manufactured synthetically. The trade name, indanthrene, was a combination of indigo and anthracene. Bohn and his colleagues expanded the indanthrene class with research on related compounds, cementing BASF’s reputation as the most innovative of the large German dye firms at the time. In 1903, Bohn added indanthrene blue GCD to BASF’s product line.1

The journey of indanthrene blue GCD began at BASF’s plant in Ludwigshafen, Germany, a city across the Rhine River from Mannheim. The plant was enormous; it had grown to more than 500 acres and hundreds of buildings since BASF’s founding in the 1860s. In 1914, more than 10,000 people worked there. Many of the buildings would have had the equipment of dyemaking, including kettles of various sizes and materials, many with mechanical stirring apparatus, autoclaves for higher pressure processes, pipes overhead, crushing mills, and gauges. The German chemical industry used the country’s rich coal deposits; the organic raw materials of the dyes were hydrocarbon distillates of coal tar, such as benzene, naphthalene, anthracene, and other aromatic organic chemicals. Then the manufacturers used inorganic acids, often hydrochloric (muriatic), nitric, and sulphuric, to make intermediates. Further processing, which could include additional reactions, washing and drying, grinding, and filtering, led to the dyes. Each stage could take several steps, and the challenge to manufacturers lay in minimizing the waste in every step and coming as close as possible to the maximum theoretical yield. In indanthrene blue dyes, the key intermediate was 2-amidoanthraquinone, derived from anthracene and cooked in an autoclave with ammonia. Melted with caustic potash (potassium hydroxide), the intermediate yielded blue indanthrene dye. By changing the temperature of the reaction or adding new ingredients, such as zinc or potassium nitrate or halogens like bromine or chlorine, the manufacturers could generate different indanthrene colors. In the case of indanthrene blue GCD, treating a basic indanthrene blue with nitric and hydrochloric acid added chlorine atoms to the molecule and shaded the blue slightly to green.2 These reactions created new chemical compounds from the organic (or carbon) base, which is what made them synthetic organic chemicals. Because manufacturers obtained their crude organic raw materials from coal tar for decades, synthetic organic chemicals were just as often called coal tar chemicals.

When complete, indanthrene blue GCD formed a paste, which BASF packaged and prepared to ship to textile manufacturers around the world. Dyes destined for the United States traveled north by railway to Rotterdam, The Netherlands, the port from which dyes were loaded onto ships bound for New York City. Indigo and many other blue dyes would be on their way to China, where blue was the most-used color. In 1913 alone, Germany exported 73 million pounds of indigo worldwide, of which 47 million went to China. Americans also consumed large quantities of blue dyes, although blacks sold in larger quantities. In 1913, the United States imported 478,980 pounds of indanthrene blue GCD, more than any other indanthrene dye, which more typically sold 2,000 or 12,000 or 20,000 pounds per year.3

The Rhine River flows north, and, downriver from Ludwigshafen, the city of Mainz sits at the junction with the Main River, on which another major chemical manufacturer stood. Not far up the Main, near Frankfurt-am-Main, Meister, Lucius & Brüning (called Hoechst, after the plant’s hometown) manufactured a full range of dyes, including synthetic indigo, and recently had achieved success with new synthetic organic pharmaceuticals. One was Novocaine (1905), a synthetic variation of cocaine that carried the pain-relieving properties of the natural drug without the addiction, and another was Salvarsan (1910), the first genuine chemotherapy, used to treat syphilis. Over 9,000 people worked at Hoechst.4

Hoechst, like most of the firms, maintained close ties to academic scientists, and Salvarsan was the product of Hoechst’s cooperation with Paul Ehrlich, the pioneer in chemotherapy and a Nobel Prize winner (1908), who directed the Institute for Experimental Therapeutics in Frankfurt. Throughout his career, Ehrlich used his synthetic dyes research to inform his medical research, borrowing theories and procedures liberally. In developing Salvarsan, Ehrlich deployed the toxic power of arsenic in combination with an aromatic organic base to kill off the spirochetes responsible for syphilis. He and his co-workers famously tried hundreds of combinations, coming up with a workable formula on the 606th arsenic compound, earning Salvarsan an alternative name, 606. In 1912, Ehrlich developed Neosalvarsan, a variation on the original that was easier for doctors to prepare and deliver to their patients. Hoechst made Salvarsan available commercially, and the American medical community eagerly awaited its arrival, which occurred early in 1911.5

When the train carrying the indanthrene blue GCD and Salvarsan arrived at Rotterdam for export, they faced international politics in the form of tariffs. Before the dyes and pharmaceuticals could depart on a ship headed to the United States, the agents of the German firms needed to show their invoices to an American consul, either at the place of manufacture and purchase or at the port of departure. The consul compared the purchasing invoice to local prices, aiming to prevent exporting firms and their agents from either dumping goods below cost in the United States or undervaluing goods to reduce U.S. customs duties. With the paperwork complete, the dyes and pharmaceuticals crossed the Atlantic Ocean in about two weeks and typically arrived in New York City, home to nearly all the American importing agencies affiliated with the German firms. The New York customs house was the nation’s largest; the customs agents there processed the arriving goods, assessing the amount of duty based on U.S. tariff rates. The customs office also ran a chemical laboratory in which they could conduct tests on incoming goods, if necessary, to help identify illegal, fraudulent, or impure products. Congress had most recently revised tariff rates in 1913, which determined the duties on Salvarsan and indanthrene blue GCD. Most dyes carried a rate of 30 percent (“ad valorem”), but the additional per pound (“specific”) rate had been eliminated in 1883. The tariff schedule imposed a duty of 15 percent on most pharmaceuticals of coal tar origin, although aspirin and a few others carried a 25 percent duty. Congress also exempted certain products entirely from tariffs, placing them on the “free list,” and in 1913 the free list included indigo and dyes from alizarin, anthracene, and carbazole. As a dye derived from anthracene, BASF’s indanthrene blue GCD passed through customs without any duty. Salvarsan carried a duty of 15 percent.6

After indanthrene blue GCD cleared customs, the BASF importing agency, which had been run for decades by Adolf Kuttroff and Paul Pickhardt, took charge of the sales in the United States. The importing agencies served as a vital cog in the machinery that delivered dyes and pharmaceuticals from German firms to American consumers. The importers understood the American market and cultivated ties to a range of consumers. Just as importantly, the importers brought important technical skills to the sales. Many operated technical laboratories to blend the chemicals or to help solve specific application problems for consumers.7

Importers taught their customers how to use their dyes and pharmaceuticals properly, and both indanthrene blue GCD and Salvarsan demanded knowledgeable users. Indanthrene dyes, like indigo, were known as “vat dyes,” which referred to their method of application. Vat dyes became soluble in a chemical solution that removed oxygen (reduction) and allowed the dye to penetrate the textile fibers, typically cotton. Upon exposure to oxygen in the air (oxidation), the dye adhered to the fiber and resisted fading or washing out much better than most other classes of dyes. The process required careful monitoring of the temperature. The importers’ technically trained sales staff worked with the dyers in the textile plants to ensure the dyers understood the best way to deploy the vat dyes.8

Salvarsan also posed serious challenges to the end user. Because arsenic was the effective toxin in Salvarsan, the consequences were dire if the attending doctor prepared or delivered the drug incorrectly. In the years before the war, several people in Europe and the United States died after receiving Salvarsan, and the medical and popular press discussed the dangers of careless delivery. In the early years, doctors needed to inject the drug intravenously within three minutes of its preparation, which eliminated preparation by pharmacists and required diligence on the part of the doctors. The solution was alkaline and typically painful for the patient to receive. Ehrlich and his coworkers developed Neosalvarsan to make delivery and reception of the drug easier, but even then deaths occurred. In April 1914, for example, eight patients died at Los Angeles County Hospital as the result of receiving decomposed Neosalvarsan. As the importer for Hoechst, Herman Metz helped to demonstrate to doctors the appropriate method of preparation and application. And, despite the deaths, doctors marveled at Salvarsan’s ability to cure syphilis, when earlier regimens had primarily treated symptoms.9

The German Dyes Industry

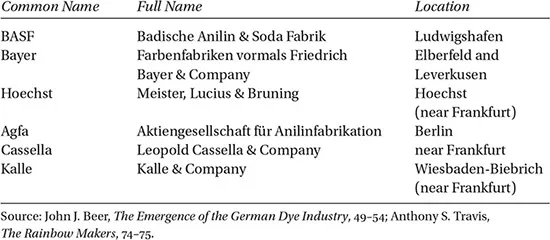

Behind such a journey of indanthrene blue GCD and Salvarsan stood a German industry that possessed four decades of impressive research, manufacturing, and global sales. After 1870, the United States and Germany developed industrially with roughly comparable timing and similar characteristics, such as strong steel and electrical industries. In its synthetic organic chemicals industry, however, Germany stood apart not only from the United States but also from Great Britain, where William Perkin synthesized the first dye in 1856, and from France, which also had a synthetic dyes industry in the 1860s. By 1914, 116 German firms had entered the dyes industry; 91 of them had also left the business. Of the thriving survivors, the most famous included the “Big Six”: the larger BASF, Bayer, and Hoechst, and the smaller Agfa, Cassella, and Kalle, nearly all founded in the 1860s. Since the 1870s, the German manufacturers had put significant distance between them and any rivals. By 1881, German firms manufactured half of the world’s synthetic dye production. As synthetic dyes improved in quality and variety, virtually replacing natural dyes, the German market share increased to between 80 and 90 percent by 1900 and remained steady for more than a decade afterward. In 1913, only Switzerland, which had five small firms that produced specialty dyes and pharmaceuticals, possessed an export market of any size, slightly less than 10 percent.10

The German industry dominated the world’s production of synthetic organic dyes between 1870 and 1914, capturing the interest of scholars for decades and yielding a rich and significant body of scholarship on this first science-based industry. Historians note that the level of technical expertise and innovation surpassed that of all other industries of the era, except for possibly the electrical industry. From the 1870s onward, German firms generated a stream of new dyes and dyes classes, synthesizing more than one thousand different dyes in a four-decade period. After the initial aniline dyes, the German manufacturers developed three key types of dyes: alizarin, azo, and vat, which rapidly replaced most of the early aniline dyes.11 A series of factors set the German industry apart from its peers: German government policies on patents, cartels, and educational support; global market and sales strategies; and, most of all, pioneering research laboratories and a full embrace of science in industrial innovation.

Table 1.1. “Big Six” German Dyes Firms

In their anger during World War I, Americans denounced the German political system and attacked policies related to synthetic organic chemicals. The rise of the German dyes industry coincided with the formation in 1871 of a unified Germany from several smaller German provinces, including the dominant Prussia under Hohenzollern monarch Wilhelm I and his chancellor, Otto von Bismarck.12 The advent of a national government shaped the political and economic context in which the firms operated, especially where government policy on cartels and competition, patents, and education were concerned.

Unlike the United States, where the antitrust legislation restricted cartel behavior, German cartels enjoyed legal sanction, which meant the cartel agreements could be enforced in courts. The German dyes industry first turned to cartels in 1881, and over the next two decades the various dyes firms signed agreements to cooperate on patents and research and to guard profits. Leaders of the dyes firms took further steps to organize their industry when they formed two rival cartel groups in 1904. Carl Duisberg of Bayer, inspired by trusts that had been recently formed in the United States (U.S. Steel and Standard Oil, for example), strove to convince the directors of the other major dyes firms to join in a single alliance. The Hoechst leadership declined Duisberg’s offer but formed one of the two groups when it exchanged stock with Cassella and, in 1907, purchased a controlling share of Kalle. In response, Bayer, BASF, and Agfa created the second cartel through a system of pooling profits. The two cartels reached agreement on the price of indigo and on a few other products and avoided price-cutting, but they remained two very distinct entities.13

The German chemical firms patented in both Germany and the United States, among many other countries. Prior to 1877 in Germany, innovations received little legal protection, a situation that facilitated German copying of British and French synthetic dyes in the 1850s and 1860s. Once German manufacturers became the originators of new processes in the 1870s, they welcomed the passage of a national patent law and sent representatives from the dye industry and academic chemistry to advise the government in the early administration of the law. Before the war, the strong patent position of the German chemical companies in the United States attracted the attention of members of the American chemical community, typically in the context of a more general fear that corporations’ research and development (R&D) and legal resources had increasingly made the U.S. patent system unfairly beneficial to the “trusts.” In 1912, a chemist counted American patents on chemicals granted between 1900 and 1910, and he determined that Germans had received 1,754 U.S. patents related to all chemicals, including more than 1,000 patents on organic chemicals. The chemist calculated that 70 percent (1,237 of 1,738) of U.S. patents granted on various synthetic organic compounds belonged to Germans. In 1915, American chemical consultant and former BASF employee Bernhard C. Hesse cited a standard German reference work from 1914 that listed 921 commercially available dyes, 207 of which U.S. patents protected. That left 714 dyes without patent protection and available to any would-be manufacturer as of 1912, according to Hesse.14

The German government also contributed to building universities and research institutes, which, coupled with the dyes firms’ pioneering industrial research laboratories, created a depth of scientific understanding and training that supported the rise of the chemical industry. German universities gained a reputation for excellence in organic chemistry, and the Kaiser Wilhelm Institutes, funded jointly by industry and the state starting in 1912, attracted top-notch scientists who focused their attention on selected research projects. Important conceptual breakthroughs led to a more precise understanding of the structure of organic chemicals and guided the search for additional syntheses. Justus Liebig’s teaching at University of Giessen from 1824 to 1852 played an important role in the development of organic chemistry. In 1860, August Kekulé formulated a structural theory of organic compounds and, in 1865, of the benzene ring, which provided a theoretical foundation for organic chemistry. Other important academic organic chemists of the late nineteenth and early twentieth century included Adolf Baeyer, Robe...