eBook - ePub

Transformer Ageing

Monitoring and Estimation Techniques

Tapan Kumar Saha, Prithwiraj Purkait, Tapan Kumar Saha, Prithwiraj Purkait

This is a test

Compartir libro

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Transformer Ageing

Monitoring and Estimation Techniques

Tapan Kumar Saha, Prithwiraj Purkait, Tapan Kumar Saha, Prithwiraj Purkait

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

A one-stop guide to transformer ageing, presenting industrially relevant state-of-the-art diagnostic techniques backed by extensive research data

- Offers a comprehensive coverage of transformer ageing topics including insulation materials, condition monitoring and diagnostic techniques

- Features chapters on smart transformer monitoring frameworks, transformer life estimation and biodegradable oil

- Highlights industrially relevant techniques adopted in electricity utilities, backed by extensive research

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Transformer Ageing un PDF/ePUB en línea?

Sí, puedes acceder a Transformer Ageing de Tapan Kumar Saha, Prithwiraj Purkait, Tapan Kumar Saha, Prithwiraj Purkait en formato PDF o ePUB, así como a otros libros populares de Scienze fisiche y Energia. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

1

Transformer Insulation Materials and Ageing

1.1 Introduction

The primary and secondary coils of a transformer are the key components in performing its basic function of transforming voltage and current. Materials are used to insulate the primary and secondary coils. In transformers, in addition to the primary and secondary coils, there are several other important components and accessories. The insulating material is one of the most critical components of a transformer. Sufficient insulation between different active parts of the transformer is necessary for its safe operation. Adequate insulation is not only necessary to isolate coils from one another, or from the core and tank, but also ensures the safety of the transformer against accidental over‐voltages.

The insulation system in a transformer can be categorized as follows.

- Major insulation:

- – between core and low‐voltage (LV) winding;

- – between LV and high‐voltage (HV) winding;

- – between top and bottom of winding and yoke;

- – between HV and tank;

- – bushings.

- Minor insulation:

- – between conductors;

- – between turns;

- – between layers;

- – between laminations;

- – between joints and connections.

The insulation material commonly used between the grounded core and the LV coil to ground, and also between HV and LV coils, is oil‐impregnated solid pressboard. Solid insulation, including pressboard or paper, can have small internal air voids. This reduces the insulating strength of the solid insulation as well as reducing its heat dissipation capacity. When transformer oil is used to impregnate solid insulation, the voids are filled with oil, resulting in an improvement of both the insulation strength and the heat dissipation capacity of the solid insulation. In larger transformers, cellulose‐based paper tape is usually wrapped over individual conductors. Layer‐to‐layer or disc‐to‐disc insulation is mostly provided by oil‐impregnated Kraft paper or even thick pressboard or transformer board in case of higher‐rating transformers.

1.2 Solid Insulation – Paper, Pressboard

The solid insulation materials widely used in the transformer are paper, pressboard, and transformer board, which are formed from the cellulose found in plants. Cellulose insulation with mineral oil has played a major role as the main insulation system for transformers for a very long time. Cellulose paper, tapes, and cloths have also been widely used. They provide excellent dielectric strength and low dielectric loss, and hence impregnated paper is now widely accepted as the insulation pillar of the electricity industry. Paper and pressboard insulation derived from pure cellulose have an excellent capacity for being impregnated with oil, thereby improving their insulation properties many times over. In addition, such solid insulating materials are easy to mold and wrap around coils, and can be made of various dimensions as per requirements.

The main concern with using dry paper as an insulating material is that it is very hygroscopic (i.e., it readily absorbs moisture). In order to overcome this deficiency, it must be dried and treated (impregnated) in some liquid (oil, varnish, resins) to reduce moisture ingress and maintain its dielectric strength. Such treatments fill the spaces between fibers and increase the dielectric strength. Nowadays, other synthetic insulating materials are used to insulate areas where the operating temperature is designed to be high (hybrid insulation), or for entire transformers specially designed to operate at high temperatures (artificial polymer – e.g., Aramid paper). Max Schaible summarized several lists of desirable qualities of high‐voltage insulation, as shown in Table 1.1.

Table 1.1 Desirable qualities for electrical grade fibers

Source: Ref. [1].

| Natural pulp (wood, cotton, hemp, etc.) | Synthetic pulp (polymers) |

| Chemical properties | Chemical properties |

|

|

| Physical properties | Physical properties |

|

|

1.2.1 Cellulose Structure

Natural cellulose comes from plants. Paper and pressboard insulation is generally made from a “Kraft” process. The typical composition of unbleached softwood Kraft is as follows:

| 75–85% | cellulose |

| 10–20% | hemicelluloses |

| 2–6% | lignin |

| <0.5% | inorganic |

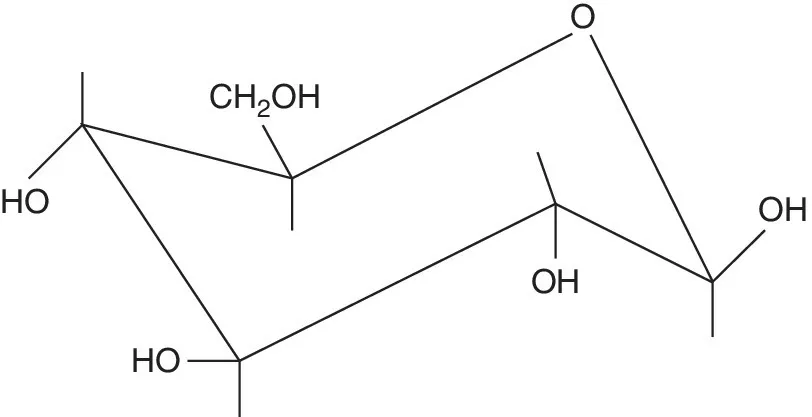

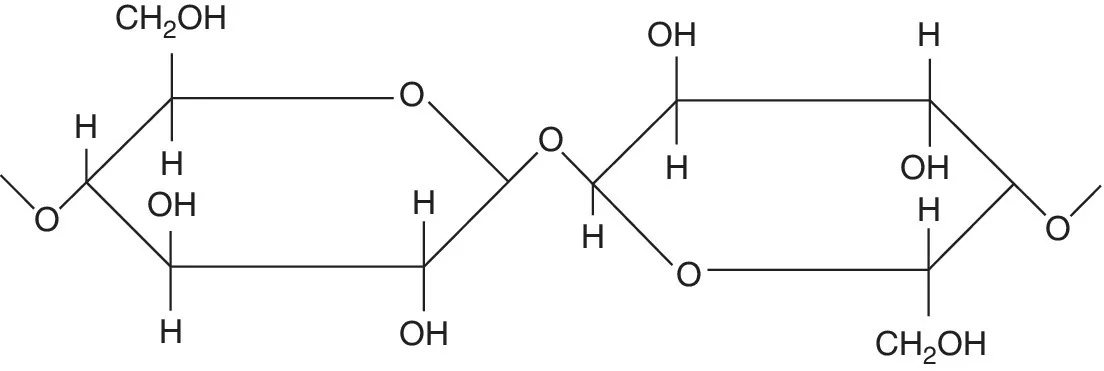

The structures of glucose and cellulose are shown in Figures 1.1 and 1.2.

Figure 1.1 Chemical structure of glucose.

Figure 1.2 Chemical structure of cellulose (polymer chains of glucose).

Cellulose is a linear polymer of anhydro‐g...