![]()

1

Bio-Based Plastics – Introduction

Stephan Kabasci

Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT, Germany

The world is becoming increasingly aware of the fact that fossil raw materials are a finite resource. Around the year 2010, circa 7 × 109 t of fossil carbon were being extracted from oil, coal and natural gas reservoirs annually. This demand has led to a considerable increase in fossil raw material prices, threatening the world's economy, and has been responsible for the rise in atmospheric carbon dioxide concentration over the past two centuries, affecting the world's climate. The massive use of fossil materials also presents an ethical problem. It can be foreseen that within a few generations these resources will be depleted. Their use needs to be reduced considerably in order to reach a sustainable level of development, defined by the UN Brundtland Commission in 1987 as: ‘development that meets the needs of the present without compromising the ability of future generations to meet their own needs’.

More than 90% of raw fossil material utilization is for the purpose of satisfying the world's energy demand. A small fraction is converted to chemical products. Regarding the energy sector, several alternative technologies have already been developed. Wind, water, solar and geothermal sources can be used to set up a sustainable energy supply. Worldwide they already constitute, for example, 20% of electricity generation. Increasing the proportion of energy that is produced from renewable sources is a social and political goal in a lot of countries.

In the chemical products sector bio-based raw materials are the only renewable alternative to replace fossil carbon sources. In some chemical product categories like, for example, detergents, renewable resources already make up a large share of the raw materials used due to their superior suitability and functionality. In the major chemical product category (with respect to the annually produced amount) of plastics, however, renewable resources still play a very small role. Nonetheless, steadily increasing numbers of bio-based polymers and products have been developed in recent years. The number of scientific papers on this topic is still growing rapidly while it remains at a constant level for traditional fossil-based polymeric materials.

This book covers a wide range of different bio-based plastics and highlights some of their applications.

1.1 Definition of Bio-Based Plastics

According to the Technical Report 15392, drawn up by the Technical Committee CEN/TC 249 of the European Committee for Standardization (CEN) in August 2009, ‘bio-based plastics’ are plastics derived from biomass. ‘Plastics’, as laid down in EN ISO 472, are materials that contain as an essential ingredient a high polymer and which at some stage in their processing into finished products can be shaped by flow. ‘Biomass’ means nonfossilized and biodegradable organic material originating from plants, animals and micro-organisms. Biomass is considered as a renewable resource as long as its exploitation rate does not exceed its replenishment by natural processes.

Although the above definition describes bio-based plastics rather unambiguously, some confusion still can be noticed, mainly due to the use of the inaccurate term ‘bioplastics’. The prefix ‘bio-’ in bioplastics sometimes is used not to indicate the origin of the material (‘bio-based’) but to express a ‘bio’-functionality of the material, in general either biodegradability or biocompatibility.

Biodegradable plastics can undergo decomposition processes induced by micro-organisms in composting or anaerobic digestion processes. Decomposition must proceed down to the ultimate stage of small molecules like methane (CH4) and/or carbon dioxide (CO2), water (H2O) and mineral salts. Different national and international standards (e.g. ASTM D 6400, EN 13 432, ISO 17 088) have been developed, in which the process criteria (e.g. temperature and time) of test procedures and methods to analyse ultimate decomposition are laid down. Only if materials tested according to one of the standards yield more than the required minimum decomposition rate may they be designated as ‘biodegradable’ with reference to the testing method. The process of biodegradation is closely linked to the molecular structure of the polymer, it does not depend on the origin of the material. Some fossil-based polymers, like polycaprolactone (PCL), or poly(butylene adipate terephthalate) (PBAT), are biodegradable according to these standards. On the other hand, there are bio-based plastics, like polyethylene (PE), from sugar cane, which are resistant to biodegradation.

Biocompatible plastics are used in medicinal applications, and the prefix ‘bio’ indicates that the polymer, when being immersed in a living organism (human or animal), does not harm the body or its metabolism in any way. These biopolymers can also be based on fossil raw materials or on renewable resources. They may be durable in the body, as in the case of artificial blood vessels, or they may disintegrate and be resorbed in the body, as in the case of resorbable suture threads.

Another form of ambiguity arises from the definition of ‘biopolymers’ in biochemistry. These are polymers synthesized by living organisms (animals, plants, algae, micro-organisms) like polysaccharides, proteins, lignin or nucleic acids. They exhibit different functions in the organisms like energy storage (starch, proteins, polyhydroxyalkanoates), structural materials (lignin, cellulose, chitin, proteins) metabolism (proteins – enzymes, nucleic acids) or information storage (nucleic acids). Direct industrial exploitation of native biopolymers is possible after extraction and purification, that is, by physical processes. Further industrial exploitation is possible by applying chemical functionalization processes to the natural polymers. Results of these physical or chemical processes can be bio-based plastics, like polyhydroxyalkanoates (PHA), or cellulose acetate (CA). On the other hand, bio-based plastics do not need to be derived from natural polymers. Poly(lactic acid), one of the most important bio-based plastics, is being produced by chemical polymerization of the bio-based monomer, lactic acid.

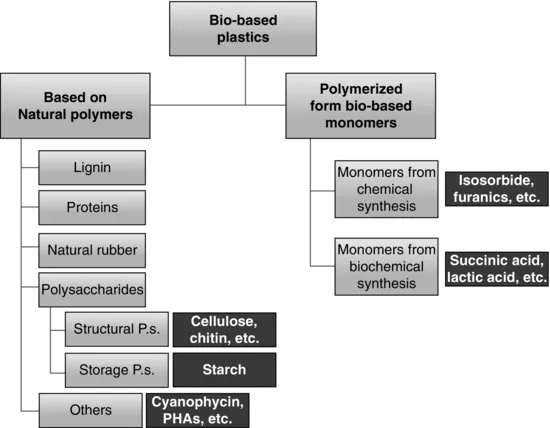

Figure 1.1 gives an overview of bio-based plastics. The distinction between materials based on natural polymers and those polymerized from bio-derived monomers can be seen from this.

Returning to the CEN definition of ‘bio-based plastics’ as plastics derived from biomass, while there is no difficulty in attesting a physically extracted natural biopolymer like polyhydroxybutyrate (PHB) to be 100% bio-based, applying chemical modifications to natural polymers or using bio-based monomers together with petrochemical monomers in a polycondensation reaction for example yields partially bio-based products. For example, 1,3-propanediol is being produced in the United States from corn starch using a biotechnological process. This monomer is 100% bio-based. By combining it with fossil-based terephthalic acid in a polycondensation reaction, a polyester, namely poly(propylene terephthalate) also known as poly(trimethylene terephthalate) (PTT), is being produced. This polyester is partially bio-based. International standardization on defining and measuring the bio-based fraction in such a material still is underway. Looking, for example, at the bio-based carbon atom content of PTT yields a bio-based fraction of 3/(3 + 8) = 27%. Nevertheless, different calculations, for example taking all chemical elements into account, are possible in principle.

1.2 A Brief History of Bio-Based Plastics

Looking at the historic development of plastics production, we can see that in the beginning it was not driven by using fossil raw materials. Quite the contrary – a lot of thermosets, elastomers and some thermoplastics were originally developed on the basis of renewable resources. Thus, the history of bioplastics in its first stages stands for the history of polymeric materials in general.

According to the German Plastics Museum, the first mention of a raw material for plastics production in the year 1530 was casein, a milk protein. A Bavarian Benedictine abbey keeps the recipe for producing artificial horn from casein. In the last decades of the eighteenth century and the first half of the nineteenth century, natural rubber was modified and used for different applications. This development ranges from the simple natural rubber eraser, described by Priestley in 1770, to Hancock's masticator in 1819, Goodyear's vulcanization process and T. Hancock's hard rubber, which was intended as a substitute for ebony, both in 1841. Soon after, in the mid-1840s, linoleum based on linseed oil (Walton) and cellulose nitrate (Schönbein) were invented. In 1854, J.A. Cutting was the first to use camphor as a plasticizer for cellulose nitrate to produce films. After an intermediate development step from Parkes, who presented the compound ‘Parkesin’ in 1856, this material combination, cellulose nitrate and camphor, was optimized by J. W. Hyatt, who created the first thermoplastic material, ‘celluloid’, in 1868. His invention was initiated by a contest for the development of a substitute material for ivory to produce billiard balls.

This bio-based plastic celluloid and its developer Hyatt gave rise to the plastics industry in the United States and worldwide. The production of celluloid billiard balls by the Albany Billiard Ball Corporation started in 1869, and three years later Hyatt constructed the predecessor of an injection moulding machine to produce parts in various shapes from celluloid. At the end of the nineteenth century the protein casein once again came under the focus of bioplastics development. In 1897 Krische and Spiteller invented Galalith, also known as Erinoid, a thermoset material from formaldehyde-hardened casein that was mainly used for the production of buttons and jewellery. In 1908, Eichengrün developed cellulose acetate, a transparent material with similar characteristics to cellulose nitrate, but with the huge advantage of being less flammable. Ten years later he also laid the foundation for the further rapid development of the plastics industry by inventing a manual piston injection moulding machine to process plasticized cellulose acetate. However, with crude oil becoming available at low prices and based on the theoretic works of Staudinger, in the 1920s and 1930s, the majority of fossil-based plastics types that are presently used (e.g. PE, PVC, PS, PA, PMMA) were developed. In these same decades, two important bio-based plastics were investigated in detail. Polyhydroxyalkanoates, which are synthesized as energy storage materials by several micro-organisms, were isolated and described by Lemoigne in 1925. Poly(lactic acid) (PLA) had been synthesized in 1913 and W.H. Carothers, one of the outstanding polymer chemists of that age, investigated the synthesis and the material in detail in 1932. Because of its biocompatibility and the ability to be resorbed in the human body, PLA and co-polyesters of lactic acid and glycolic acid have been produced for medical applications since the 1950s. Another bio-based raw material, castor oil, was exploited from the 1940s, when undecenoic acid, one of the pyrolytic degradation products of ricinoleic acid, was firstly used in the production of polyamide 11. After this, some decades of massive growth in production of fossil-based plastics followed and materials like PE, PVC, PS, PMMA and later on PP have been dominating the plastics world.

In parallel to the upcoming environmental protection movements of the 1980s, the awareness of the need for replacing fossil-based raw materials increased. The use of starch for the production of bioplastic materials was investigated and the first materials based on this research entered the market in the 1990s. In that same decade, high-volume production of PLA for nonmedicinal use started and the first tests of biodegradable PHA packaging materials were performed. Ten years later, considerable production capacity for several types of bio-based polymers had built up. With the advent, in particular, of fully bio-based drop-in materials, like bio-polyethylene (Bio-PE), and partially bio-based drop-in materials, like bio-poly(ethylene terephthalate) (Bio-PET with bio-derived ethylene glycol), production capacities of bioplastics surpassed 1 million t in 2011.

1.3 Market for Bio-Based Plastics

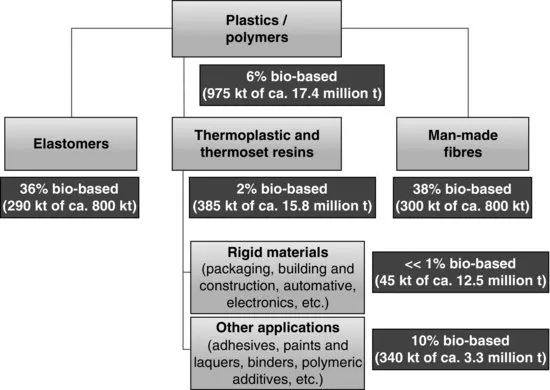

Looking at the different types of plastics and their applications large differences in the share of bio-based materials can be found. In 2010, the German Federal Agency for Renewable Resources presented data for the German market in the year 2007, which was analysed in three different sectors: thermoplastic and thermoset resins, elastomers, and man-made fibres (Figure 1.2).

The proportion of bio-based materials in each of the sectors of elastomers and fibres accounted for almost 40% due to the use of 290 000 t of natural rubber and 300 000 t of cellulosic fibres. The market size for thermoplastics and thermosets amounted to circa 15.8 million t, of which circa 12.5 million t accounted for rigid materials, mainly in packaging, building and construction, automotive and electronics industries as well as for furniture and consumer goods. A volume of 3.3 million t is attributed to adhesives, paints and lacquers, binders and other polymeric additives. In these areas it is estimated that bio-based materials hold a share of circa 10%, while in the sector of rigid materials the bio-based plastics market size of 45 000 t merely amounts to circa 0.4% of the total market size.

A lot of market studies focus on thermoplastic bio-based plastics as rigid materials, describing the present status of these materials and predicting future growth rates. In this plastics application segment, global annual production capacity of bio-based materials surpassed 1 million t in 2011. Despite the low absolute value, bio-based plastics saw a rapid increase in production capacity, for example from 2003 (100 000 t) to 2007 (360 000 t), with a continuous average growth rate of 38% p.a.

For the near future this trend will continue. According to a study from the European Bioplastics association and the University of Applied Sciences and Arts of Hannover, this value will increase fivefold to an estimated 5.8 million t in 2016. The main driver of such an enormous expected rise is attributed to the 2011 decision of a leading worldwide soft drink company to substitute all of their PET bottles by (at least) partly bio-based PET, in which the ethylene glycol unit is derived from bioethanol – accounting for 4.6 million t. Thus, production capacity for bio-based drop-in commodity plastics (Bio-PET and Bio-PE) will largely overtake that of biodegradable materials. Poly(lactic acid), for example, was the predominant bio-based plastics material from 2000 to 2010, with annual production capacities of 100 000–150 000 t in this decade. This bio-based and biodegradable resin is predicted to undergo a twofold production capacity increase up to circa 300 000 t in 2016, too. Despite this rise, its share of the overall bio-based plastics market will drop from circa 35% to merely 5%.

Looking generally at the broad range of bio-based plastic types, most studies agree upon a growth of production capacities due to more and more companies entering and investing in the market. In 2009, circa 20 companies held 90% of the bioplastics market. By 2015 more than 250 and by 2020 over 2000 companies are expected to be at that market. Asia and South America will most likely have the highest growth rates and investments in the next decade.

Caused by the foreseen increase in Bio-PET production until 2016, bottles together with other packaging applications will be the dominant usage sectors of bio-based plastics. Nevertheless, progress in the development of processing and functional additives like, for example, flame retardants will also enhance the use of bio-based plastics in semi-durable and durable applications like transportation, construction, electronics, furniture and consumer goods in general. Key issues in all of these areas in general are material-, process-, and eco-efficiency. Common requirements for distinct material...