eBook - ePub

Solid/ Liquid Separation

Principles of Industrial Filtration

Stephen Tarleton, Richard Wakeman

This is a test

Condividi libro

- 340 pagine

- English

- ePUB (disponibile sull'app)

- Disponibile su iOS e Android

eBook - ePub

Solid/ Liquid Separation

Principles of Industrial Filtration

Stephen Tarleton, Richard Wakeman

Dettagli del libro

Anteprima del libro

Indice dei contenuti

Citazioni

Informazioni sul libro

Solid/fluid separation is a major element in the processes performed in pharmaceutical, food, beverage, water, pulp and paper industries. Several books now exist on the more esoteric aspects of the techniques, but accounts of the fundemental principles involved are few.

Written by two well-known chemical engineers, this book reviews the scientific and engineering bases for solid/fluid separation processes in an approachable style. Coverage focuses on fluid dynamics, gravity, centrifugal and membrane separations, filter cake formation, de-liquoring and washing. Complete with an extensive bibliography to allow readers to pursue topics in greater depth.

- Help readers to understand how filtration processes work

- Facilitate the application of knowledge to start-up and existing processes, helping readers to improve process performance

- Help ensure your equipment is appropriate for its purpose and is working optimally, saving time and money

Domande frequenti

Come faccio ad annullare l'abbonamento?

È semplicissimo: basta accedere alla sezione Account nelle Impostazioni e cliccare su "Annulla abbonamento". Dopo la cancellazione, l'abbonamento rimarrà attivo per il periodo rimanente già pagato. Per maggiori informazioni, clicca qui

È possibile scaricare libri? Se sì, come?

Al momento è possibile scaricare tramite l'app tutti i nostri libri ePub mobile-friendly. Anche la maggior parte dei nostri PDF è scaricabile e stiamo lavorando per rendere disponibile quanto prima il download di tutti gli altri file. Per maggiori informazioni, clicca qui

Che differenza c'è tra i piani?

Entrambi i piani ti danno accesso illimitato alla libreria e a tutte le funzionalità di Perlego. Le uniche differenze sono il prezzo e il periodo di abbonamento: con il piano annuale risparmierai circa il 30% rispetto a 12 rate con quello mensile.

Cos'è Perlego?

Perlego è un servizio di abbonamento a testi accademici, che ti permette di accedere a un'intera libreria online a un prezzo inferiore rispetto a quello che pagheresti per acquistare un singolo libro al mese. Con oltre 1 milione di testi suddivisi in più di 1.000 categorie, troverai sicuramente ciò che fa per te! Per maggiori informazioni, clicca qui.

Perlego supporta la sintesi vocale?

Cerca l'icona Sintesi vocale nel prossimo libro che leggerai per verificare se è possibile riprodurre l'audio. Questo strumento permette di leggere il testo a voce alta, evidenziandolo man mano che la lettura procede. Puoi aumentare o diminuire la velocità della sintesi vocale, oppure sospendere la riproduzione. Per maggiori informazioni, clicca qui.

Solid/ Liquid Separation è disponibile online in formato PDF/ePub?

Sì, puoi accedere a Solid/ Liquid Separation di Stephen Tarleton, Richard Wakeman in formato PDF e/o ePub, così come ad altri libri molto apprezzati nelle sezioni relative a Technology & Engineering e Mechanical Engineering. Scopri oltre 1 milione di libri disponibili nel nostro catalogo.

Informazioni

Argomento

Technology & EngineeringCategoria

Mechanical Engineering1

Introduction

In the simplest sense solid/liquid separation involves the separation of two phases from a suspension. Although a filter is the kernel of most solid/liquid separations, a vast array of other techniques and equipment are available to effect a separation, ranging from highly versatile units capable of handling different filtration duties to those restricted in use by the fluid properties and process conditions. Filtration, or more generally solid/liquid separation, is used in many processes with one or more aims:

1. recovery of a valuable solid component (the liquid being discarded);

2. recovery of the liquid (the solids being discarded);

3. recovery of both the solids and liquid phases; or

4. recovery of neither phase (e.g. when a liquid is being cleaned prior to discharge, as in the prevention of water pollution).

Not only is the nature of the “product” important, but a further serious consideration in the selection of solid/liquid separation equipment is whether the separation is to be effected continuously or batchwise. In the latter case the separator is operated intermittently between filling and discharge stages of its operating cycle. Scale or throughput during operation also requires careful consideration, as scale not only affects equipment size but many separator designs make them suitable for limited ranges of throughput.

1.1 The separation process

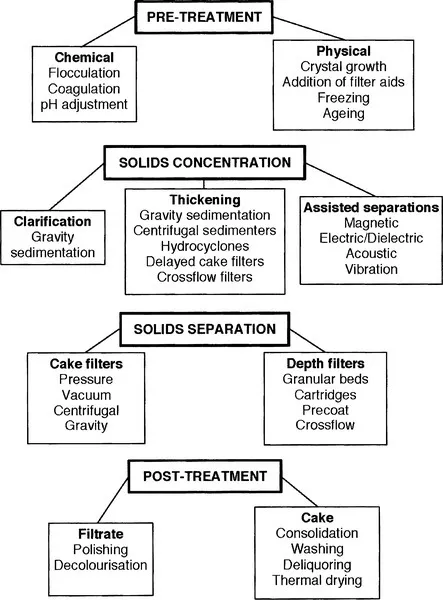

Any system design must consider all stages of solid-liquid separation, including pre-treatment, solids concentration, solids separation and post-treatment. These factors encompass the wide range of equipment and processes summarised in Figure 1.1.

Figure 1.1 Some components of the solid/liquid separation process. A number of the separation processes above may be used alternatively as pre-treatment, solids concentration or solids separation techniques.

Pre-treatment is used primarily with “difficult to filter” slurries, enabling them to be filtered more easily. A slurry may be difficult to filter for a variety of reasons — for example, a proportion of the particles in the feed may be fine and tend to block the entrances to pores in a filter medium, or the concentration of particles in the feed may be low and cause surface or internal blocking of the filter medium, or the surface chemistry of the particles may cause them to gel or be attracted to the filter medium surfaces irreversibly, and so on. Pre-treatment usually involves changing the nature of the suspended solids by either chemical or physical means, or by adding a solid (filter aid) to the suspension to act as a bulking agent to increase the permeability of the cake that is formed during filtration. Some pre-treatment processes, notably chemical processes, simultaneously change the properties of the suspending liquid.

During concentration of the solids in a suspension part of the liquid is removed, for example by gravitational or centrifugal thickening or hydrocycloning. This reduces the liquid volume throughput load on a filter and generally enables a filter cake to be formed more readily. A number of “assisted separation” techniques are also gradually making their way into the list of technical alternatives available to the separations technologist – these utilise magnetic, electrical or sonic force fields either individually or in combination to provide for a more effective separation. Although still quite uncommon in practice, their existence should be recognised.

Solids separation usually involves a filter, the types of which can be classified in many different ways. For present purposes, the divisions in Figure 1.1 indicate those separations in which a cake is formed and those where the particles are captured in the depth of the medium is adequate. These general categories hide the complexities associated with the wide range of filter types available, which often causes confusion for people who do not need to have an in-depth knowledge of filtration problems and applications. The underlying fundamental models and approaches to the analysis of solid/liquid separation problems, which can also be used for the scale-up and sizing of filter systems, are amplified in this book. Cake filters can be further divided into pressure, vacuum, centrifugal and gravity operations.

Post-treatment processes involve making improvements to the quality of the solid or liquid products. In the case of the liquid product, the filtrate, these operations are often referred to as polishing processes. Polishing may involve, for example, fine filters to remove small contaminants from the filtrate. Further purification could involve removal of ionic and macromolecular species by reverse osmosis, ion exchange or adsorption. Cake post-treatment processes include washing soluble impurities from the cake voids, and the removal of excess liquid from the voids to reduce the cake moisture content.Thermal drying is often the final stage of liquid removal from the solids that are discharged from a filter as a cake.

1.1.1 Solid/liquid separation in the process flowsheet

Solid/liquid separation is too often designed as though it is a ‘standalone’ process in a plant flowsheet — taking a traditional unit operations textbook approach. The performance of a solid/liquid separation device is sensitive to the history of the feed suspension, for example on the characteristics of the particles which result from conditions during precipitation or crystallization. Changes in the operating conditions of the particle production process often alter the mean size, the size distribution or the shape of the particles in the slurry fed to a filter, each of which can have a profound effect on the characteristics of separation and hence on the performance of a filter. This is turn means that a change in particle production conditions can affect the best choice of filter for a separation! All too often the choice of solid/liquid separation equipment is perceived to be between alternative separator types – for example between a centrifuge and a rotary vacuum filter. In fact the situation is considerably more complex as many equipment items up- and down- stream of a separator are frequently interdependent, and all ancillary equipment must be included in an analysis of the separation process. The choice of ancillary components varies according to the type of separator and the flowsheet, and on other units in the process. It is often possible to devise a multiplicity of solutions to any separation problem that lead to alternative process flowsheets.

The economics and viability of producing a product are often affected by the amount of liquid removed in post-treatment processes. For example, if the cake is to be transported, briquetted or pelletized the cake moisture content will need to be within a specified range, or if a bone dry product is required the thermal load on the dryers can be reduced by correct choice and operation of the filter.

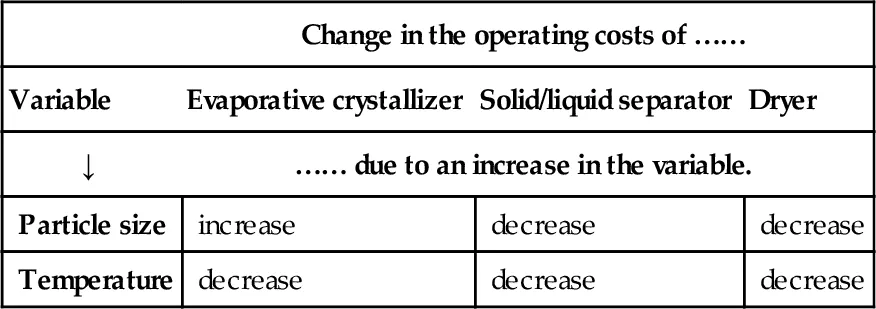

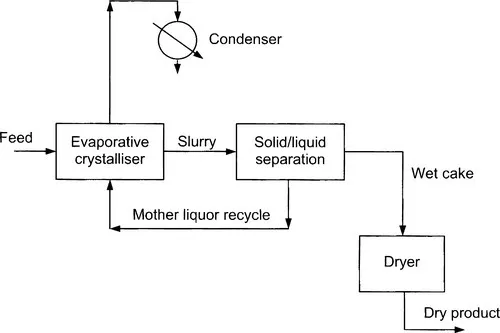

Where interactions between process steps exist “local” and “global” trade-offs are identifiable — that is, the operation of one or more pieces of equipment may not be optimal if the overall flowsheet is optimised. Local trade-offs affect single items of equipment, whilst effects of global ones manifest themselves on the design of more than one item of equipment. Consequently the latter are of considerable importance when defining optimum design and operating conditions for a process as a whole. Consider the simple flowsheet shown in Figure 1.2 for the recovery of particles from an evaporative crystalliser. In this case particle size and temperature are major global variables and the effect of increasing either variable on the unit operation cost can be summarised as:

Figure 1.2 Possible simplified flowsheet structure for particle production.

| Change in the operating costs of …… | |||

| Variable | Evaporative crystallizer | Solid/liquid separator | Dryer |

| ↓ | …… due to an increase in the variable. | ||

| Particle size | increase | decrease | decrease |

| Temperature | decrease | decrease | decrease |

Here two different effects of global variables are observed. Increasing the particle size usually enables easier separation and less moisture in the discharged cake, resulting in reduced costs for both separation and drying. However, the crystallizer size and cost are increased and an “optimum” particle size may be sought when size is not governed by market criteria or required properties of the particle. Increasing the temperature, on the other hand, leads to lower costs in all three unit operations — hence the “best” temperature will be one close to the temperature of an available utility such as steam. This is but one quite simple example, and each process flowsheet requires investigation in its own right using information pertinent to the particular problem.

On Figure 1.2 minor global variables can also be identified between two equipment items. Operating at higher slurry densities in the crystallizer take-off can reduce the size of both the crystallizer and the separator. Producing a drier filter cake tends to increase mechanical separation costs, but reduce thermal dryer costs. Hence an optimum moisture content can be sought.

It is important, therefore, to consider simultaneously and to the same detail those unit operations that supply suspension to the solid/liquid separations plant, and the subsequent processing of the solid or liquid prod...