![]()

Part I

Single Screw Extrusion

Outline

1 Extrusion Process

2 Extruder Safety

3 Single Screw Extruder

4 Plastic Behavior in the Extruder

5 Screw Design

6 Processing Conditions

7 Scale-Up

8 Shear Rates, Pressure Drops, and Other Extruder Calculations

![]()

1

Extrusion Process

Abstract

The extrusion of polymeric materials to produce finished products for industrial or consumer applications is an integrated process, with the extruder comprising one component of the entire line. In some applications, the production lines are very long with numerous operations, requiring operators to communicate and work together to produce an acceptable finished product. If the extruder temperature profile is set incorrectly, the product ingredients are not properly formulated, the cooling on the extruder feed throat is not running properly, the melt temperature at the end of the extruder is incorrect, the cooling bath temperature is not set correctly, the puller at the end of the line is running at the wrong speed, or any other incorrect operating condition or combinations of conditions exist, the product may not meet customer specifications. Each step in the process adds value; consequently, the product reaches its maximum value at the end of the line. An improper setting at the beginning of the process may cause the product to be unacceptable at the end of the line after significantly more value has been added. Speeds of the different process steps must be matched to ensure product compliance.

Keywords

Blending; Extrusion; Polymer; Raw Material

The extrusion of polymeric materials to produce finished products for industrial or consumer applications is an integrated process, with the extruder comprising one component of the entire line. In some applications, the production lines are very long with numerous operations, requiring operators to communicate and work together to produce an acceptable finished product. If the extruder temperature profile is set incorrectly, the product ingredients are not properly formulated, the cooling on the extruder feed throat is not running properly, the melt temperature at the end of the extruder is incorrect, the cooling bath temperature is not set correctly, the puller at the end of the line is running at the wrong speed, or any other incorrect operating condition or combinations of conditions exist, the product may not meet customer specifications. Each step in the process adds value; consequently, the product reaches its maximum value at the end of the line. An improper setting at the beginning of the process may cause the product to be unacceptable at the end of the line after significantly more value has been added. Speeds of the different process steps must be matched to ensure product compliance.

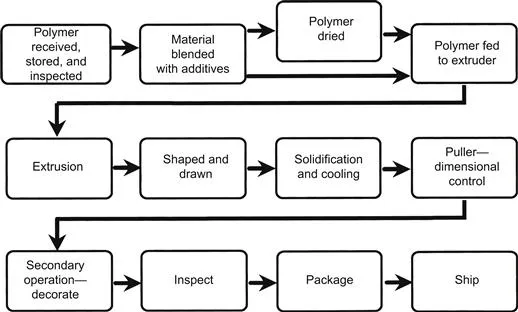

The extrusion process is shown in Figure 1.1. Polymeric material is received, inspected, and stored. Before extrusion, the polymer may be blended with additives (stabilizers for heat, oxidative stability, ultraviolet stability, etc.), color pigments or concentrates, flame retardants, fillers, lubricants, reinforcements, etc., to produce the desired product property profile. Some resin systems must be dried before extrusion to eliminate polymer degradation due to moisture. Other resins, which do not normally require drying, may have to be dried if they are stored in a cold warehouse and brought into a warm environment, causing moisture to condense on the surface of the pellets, flake, or powder. Once the polymer or blend is properly dried and ingredients mixed, the formulation is fed into the extruder, where it is melted, mixed, and delivered to the die to shape the extrudate. After exiting the die, the product is cooled and solidified in the desired shape and pulled away from the extruder at a constant velocity to attain the appropriate cross-section. Secondary operations, i.e. flame treatment, printing, cutting, annealing, etc. can be done in line after the puller. Finally, the product is inspected, packaged, and shipped.

Figure 1.1 Schematic of a basic extrusion process.

The different parts of the process are discussed in more detail in this chapter.

1.1 Raw Material Supply

Polymer resin is shipped in different-sized containers depending on the quantity ordered, the processors' handling and storage capability, and the way the extruder is fed. Small lots are shipped in 50- or 55-lb bags, and large lots are shipped by tanker trucks or rail. Table 1.1 shows the different shipping methods. Plastic pellets can be air or vacuum conveyed around the plant to storage containers or the extruder hopper.

Table 1.1

Plastic Packaging

| Package Size, lb | Type Package |

| 50–55 | Bags |

| 300 | Fiber pack |

| 1000 | Gaylord |

| 4000 | Bulk pack |

| 40,000 | Hopper truck |

| 150,000–220,000 | Rail car |

Pellets conveyed between storage silos, dryers, surge hoppers, and extruder hoppers must be in dedicated or properly cleaned lines to prevent product cross-contamination. All lines must be properly grounded to eliminate static electricity build-up during the resin transfer process.

Raw materials stored in warehouses without environmental controls (lack of heat or cooling) need to be brought to room temperature before extrusion. If the raw material temperatures vary between summer and winter, the polymer melting or softening point in the extruder will occur at a different location, leading to different melt viscosities, extrudate flow, and possible product inconsistency from season to season. Assume the raw material temperature is 50 °F (10 °C) in the winter and 80 °F (26 °C) in the summer. Additional heat must be applied to the raw material during the winter months, either by a hopper dryer, allowing the polymer to come to equilibrium at room temperature, or by adding additional heat in the first zones to ensure the polymer is melting or being plasticated in the transition zone. Due to the insulative nature of polymers, a significant time period is required to heat cold pellets that sat in a cold warehouse or in a cold truck to room temperature.

Storing raw materials in a hot environment over an extended time can lead to consumption of the polymer stabilization package. Most thermal stabilization packages are consumed over time as the polymer is heated. While thermal degradation happens fairly rapidly at elevated temperatures in the presence of oxygen, degradation continues at a slower rate at elevated temperatures (above room temperature but below the melting or softening temperature). Stock should be rotated to minimize long-term thermal degradation.

Many raw materials are accepted from vendors based on a “certificate of compliance”. Good procedures dictate that incoming raw materials be periodically tested and a database of critical polymer properties be established. Most internal extrusion problems are not the result of raw material variations; however, in the event the wrong raw material is used, the processor should be able to identify any raw material inconsistencies immediately to minimize operating losses. Critical raw material properties for a particular application need to be identified and characterized so that incoming materials are tested only for the properties that affect the final part performance. Critical properties may be viscosity, long-term heat aging, color, tensile properties, or other parameters, depending on the particular end-use application.

1.2 Raw Material Blending and Mixing

Depending on the product requirements, some preblending or ingredient mixing may be required before extrusion. (Blending and mixing are covered in more detail in Part 5, “Aux...