eBook - ePub

Material Requirements Planning with SAP S/4HANA

Caetano Almeida

This is a test

Condividi libro

- 541 pagine

- English

- ePUB (disponibile sull'app)

- Disponibile su iOS e Android

eBook - ePub

Material Requirements Planning with SAP S/4HANA

Caetano Almeida

Dettagli del libro

Anteprima del libro

Indice dei contenuti

Citazioni

Domande frequenti

Come faccio ad annullare l'abbonamento?

È semplicissimo: basta accedere alla sezione Account nelle Impostazioni e cliccare su "Annulla abbonamento". Dopo la cancellazione, l'abbonamento rimarrà attivo per il periodo rimanente già pagato. Per maggiori informazioni, clicca qui

È possibile scaricare libri? Se sì, come?

Al momento è possibile scaricare tramite l'app tutti i nostri libri ePub mobile-friendly. Anche la maggior parte dei nostri PDF è scaricabile e stiamo lavorando per rendere disponibile quanto prima il download di tutti gli altri file. Per maggiori informazioni, clicca qui

Che differenza c'è tra i piani?

Entrambi i piani ti danno accesso illimitato alla libreria e a tutte le funzionalità di Perlego. Le uniche differenze sono il prezzo e il periodo di abbonamento: con il piano annuale risparmierai circa il 30% rispetto a 12 rate con quello mensile.

Cos'è Perlego?

Perlego è un servizio di abbonamento a testi accademici, che ti permette di accedere a un'intera libreria online a un prezzo inferiore rispetto a quello che pagheresti per acquistare un singolo libro al mese. Con oltre 1 milione di testi suddivisi in più di 1.000 categorie, troverai sicuramente ciò che fa per te! Per maggiori informazioni, clicca qui.

Perlego supporta la sintesi vocale?

Cerca l'icona Sintesi vocale nel prossimo libro che leggerai per verificare se è possibile riprodurre l'audio. Questo strumento permette di leggere il testo a voce alta, evidenziandolo man mano che la lettura procede. Puoi aumentare o diminuire la velocità della sintesi vocale, oppure sospendere la riproduzione. Per maggiori informazioni, clicca qui.

Material Requirements Planning with SAP S/4HANA è disponibile online in formato PDF/ePub?

Sì, puoi accedere a Material Requirements Planning with SAP S/4HANA di Caetano Almeida in formato PDF e/o ePub, così come ad altri libri molto apprezzati nelle sezioni relative a Computer Science e Computer Science General. Scopri oltre 1 milione di libri disponibili nel nostro catalogo.

Informazioni

1 Introduction to MRP with SAP S/4HANA

Material requirements planning (MRP) is the central planning tool used widely across companies of many different industries. The main objective of MRP is to ensure that we will have enough of the materials that we need, with the best possible service level, and at minimal cost.

We will begin this book in this chapter by explaining core MRP concepts (Section 1.1), situating them in the context of the broader supply chain as run in SAP systems (Section 1.2), and then turning our attention to MRP as it exists in SAP S/4HANA (Section 1.3).

1.1 MRP Basics

MRP will start by planning the top-level materials (i.e., the finished products), taking all the requirements—a forecast in a make-to-stock (MTS) production environment or a sales order in a make-to-order (MTO) environment—as inputs and checking if we have enough stock to cover them. If there is not enough stock, the system will check if there is any planned receipt—such as a production order or purchase order—that can cover the requirement. When there is not enough stock and no planned receipt, MRP will generate a replenishment proposal to let us know that we need to buy or produce this material.

For a finished product that is manufactured internally, the replenishment proposal created by MRP is a planned order. For each planned order, MRP will calculate the dates based on a predefined lead time in order to ensure that we will start the production on time to meet the requirement. For each planned order, MRP will determine the components based on a predefined list called a bill of materials (BOM). It will create dependent requirements for each component, indicating the date and quantity needed.

The dependent requirements generated by MRP will then act as inputs for MRP to plan the components. MRP will plan the semifinished products, level by level, until reaching the raw material level. At this point, the system will generate purchase requisitions, informing us that we need to buy those materials from a supplier.

This is the basic process of a deterministic MRP type, where the main input will be requirements for a finished product and the output will be planned orders or purchase requisitions for this finished product for all component levels.

During the MRP run, exception messages will be triggered whenever an issue arises that cannot be solved automatically. For example, if MRP determines that the start date of a planned order should be in the past (which would be impossible), it triggers an exception message to inform the planner (known as an MRP controller) about it. After the MRP run, a planner should evaluate the MRP results and check if any action should be performed to resolve the issue.

This process is repeated cyclically, and whenever a new requirement is created for a material or there is a relevant change in the stock or a planning element, it is marked to be included in the next planning run. In most companies, MRP is usually executed on a daily basis to plan all the changed materials, plus once a week to replan all the materials, irrespective of the changes.

1.2 MRP within the Supply Chain in SAP Systems

MRP is one of the planning tools that SAP provides for companies to manage their whole supply chain, from forecasting and production planning through purchasing, manufacturing, and finished goods delivery to the customer.

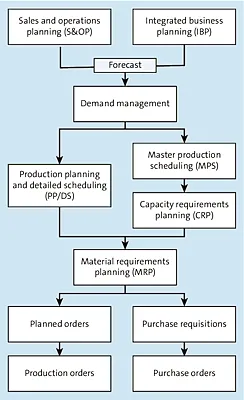

Let’s walk through this supply chain flow as performed in SAP S/4HANA and outlined in Figure 1.1. From a production planning perspective, everything will start with a forecast of the quantities that should be produced in each period (e.g., months, weeks, or days). This forecast was traditionally created in sales and operations planning (S&OP) functionality offered as part of SAP ERP or SAP Advanced Planning and Optimization (SAP APO).

S&OP is still available in SAP S/4HANA, and integration of SAP S/4HANA with SAP APO is still supported, but SAP recommends that S&OP be run in the successor of SAP APO: a cloud solution called SAP Integrated Business Planning (SAP IBP). SAP IBP generates the forecast that can be used as an input for the planning process in SAP S/4HANA.

Figure 1.1 Production Planning in SAP S/4HANA

The forecast generated by S&OP (either in SAP APO or in SAP S/4HANA) or by SAP IBP is then transferred to a functionality within SAP S/4HANA called demand management, where this forecast will become what we call planned independent requirements (PIRs). Each material will have a planning strategy, and this planning strategy will determine which type of PIR is created and how this material will be planned; for example, we can plan to produce our material to stock (MTS production) or to start the production only after we receive a sales order (MTO production).

In an MTS scenario, we usually rely on the forecast to start the production ahead of time, but in an MTO scenario, this is not always true. In a pure MTO scenario, we will only start the production when we receive a sales order, so the only input for MRP will be the sales order. Alternatively, we might use a forecast in an MTO scenario to start the procurement of some components ahead of time.

After we generate the independent requirements in demand management, we start the actual materials planning. Often, companies will use master production scheduling (MPS) for planning finished products, important semifinished products, or products that will use bottleneck production lines.

Note

Technically speaking, MPS and MRP in SAP S/4HANA are pretty much the same thing, and they even can be executed in the same transaction.

However, because neither MPS nor MRP take into account capacity restrictions, it is advisable to split the planning run between MPS and MRP and to run capacity leveling for the products planned with MPS before running MRP.

MPS will plan the products mentioned previously, just like deterministic MRP would plan them, generating replenishment proposals whenever it finds a shortage. After we finish the MPS planning run, we can run capacity leveling to ensure that the plan proposed by MPS will not exceed the critical resources capacity. Figure 1.1 shows this capacity leveling as a step between MPS and MRP.

With capacity leveling, we might have to shift some planned order dates in the event of a capacity overload, so we will automatically adjust the dates of the component requirements. Therefore, when MRP is executed, it will consider those adjusted dates and generate a realistic plan that will already consider capacity restrictions. This way, we will be generating purchase requirements for our suppliers with the actual required dates, according to our plant capacity.

Tip

Capacity leveling can also be executed as a background job, so it is possible to have MPS, capacity leveling, and MRP executed as a sequence of background jobs that run overnight.

As also shown in Figure 1.1, an alternative to MPS is to use the Production Planning and Detailed Scheduling (PP/DS) tool, formerly part of SAP APO, which SAP embedded into the SAP S/4HANA digital core. PP/DS supports advanced planning features that are not available in MPS or MRP, such as planning with finite capacity (i.e., considering capacity restrictions on the work centers), planning considering the batch shelf life, or planning with complex heuristics.

Whereas PP/DS in SAP APO was a separate application running in a different system than MRP, MRP Live in SAP S/4HANA can plan both advanced planning PP/DS materials and MRP materials. PP/DS provides not only tools for materials planning, but also tools for optimizin...