![]()

1 Computer-Aided Design and Manufacture

What aspects of design and workshop manufacturing can computer software help with? This chapter aims to answer this question by clarifying established methods for product or engineering design, discussing the role of computer-aided techniques in those methods, and providing an overview of CAD technology.

WHAT IS DESIGN?

The word ‘design’ has a range of meanings, and the following sub-sections cite several definitions, each similar and complementary. Considering all of them may help you to develop your own understanding of what design means.

The dictionary definition: The Hugo English Pocket Dictionary defines ‘design’ as a verb, meaning to plan out, intend, make, invent or pattern, and as a noun, meaning an intention, a plan, a purpose or a decorative pattern.

Bettina Von Stamm’s definition: Bettina Von Stamm, a recognized expert in the field of design and innovation management, presented three definitions of design in her book Managing Innovation, Design and Creativity:

♦ Design is the tangible outcome – that is, the end product such as cameras, cars, and so on

♦ Design is a creative activity

♦ Design is a process by which information is transformed into a tangible outcome

In her discussion of the definition of design Stamm emphasizes design as being a conscious decision-making process, and presents this explanation: ‘Design is the conscious decision-making process by which information (an idea) is transformed into an outcome, be it tangible (a product) or intangible (a service).’

The UK-SPEC definitions: In the UK, the definition and recognition of professional competencies in engineering is managed by the Engineering Council: they define what chartered engineers, incorporated engineers and engineering technicians should be able to do, and these definitions are summarized in a document called the UK-SPEC (United Kingdom Standard for Professional Engineering Competence). This document recognizes design as a specific skill, stating that:

‘Design is the creation and development of an economically viable product, process or system to meet a defined need.’

Noel Carrington’s definition: In his book The Shape of Things, published in 1939, Noel Carrington defines design as ‘purpose’ + ‘material’ + ‘technique’: ‘what you are doing something for’ + ‘what you will do it with’ + ‘how you will do it’.

Although a simple definition, it does summarize rather concisely the range of tasks or problems a designer is typically engaged with when he is designing, defining or specifying the requirements, and then creating solutions to meet those requirements.

British Standard BS 7000 – design vocabulary: The British Standard BS 7000-10:2008, design management systems – the vocabulary of terms used in design management – describes design as follows:

♦ As a verb: to generate information by which a product can become a reality

♦ As a noun: a set of instructions (specifications, drawings, schedules) necessary to construct a product

♦ As a process, and it describes three phases:

Concept design phase: Preliminary research and studies to establish design alternatives that merit further development.

Embodiment design: The process in which a structured development of the preferred concept is carried out.

Detail design: The process in which the precise shape, dimensions and tolerances, materials and manufacturing process are all defined.

The author’s definition: A design is a plan, a set of instructions, a set of drawings, a description or some other manifestation of a product. Designing is the process of creating a solution to a specific problem, resulting in the definition of a product.

THE ACRONYMS USED FOR SPECIALIST SOFTWARE

There are many acronyms used for specialist software in the field of engineering, design and manufacture. The most significant ones are CAD, CADD, MCAD, CAE, FEA, DFM and CAM, and these are clarified here:

CAD: Computer-aided design: The ‘D’ used to stand for drafting. CAD relates to design- and drafting-related software and any related system of computing hardware.

CADD: Computer-aided drafting and design: An older acronym, similar to CAD, but intentionally including an extra ‘D’ to indicate the system’s design functionality as well as the original drafting functionality.

MCAD: Mechanical computer-aided design: Used for mechanical engineering and product design-oriented software. It distinguishes a software product from other specialist CAD software, such as those used by the construction or electronics sectors, for example.

CAE: Computer-aided engineering: This acronym can apply to any software that simulates some aspect of behaviour of the design. The behaviour may relate to the dynamic motion of a mechanism, or the structural (strength and stiffness) properties of a component under load.

FEA: Finite element analysis: A specific type of analysis that enables the characteristics of a component, such as structural strength, stiffness or heat conduction, to be investigated.

DFM: Design for manufacture: A specific approach to design that actively considers the limitations and benefits of the materials and processes available for production.

CAM: Computer-aided manufacture: CAM software facilitates the preparation of the required data files used for CNC machine operation, usually working directly with 2D or 3D CAD model files.

HOW TO DESIGN: APPLYING A PROCESS

When engaged in designing you are striving to produce some kind of object or product that meets defined requirements. You are creating or developing something new, in one form or another. You are working with intention, within the restraints provided by materials and processes.

In order to work efficiently, a structured approach to the design activities may help. Much research and development work has been done in this field, as the large number of books available on the subject suggests. Most design management methods are systematic and will generally involve these stages:

♦ Statement of need or requirement, resulting in a design brief

♦ Development of a design specification, defining its needs or requirements

♦ Initial generation of solutions or ideas, often referred to as the ‘concept design’ phase

♦ Analysis of these ideas with respect to specification

♦ Selection and development of the preferred solution or solutions

♦ Embodiment design

♦ Detail design

♦ Delivery – final documentation, communication, manufacture

Many experienced designers may be applying a process such as this intuitively, without drawing distinctions between the stages, or even being aware of them. They may have spent many years learning by experience what works. If you lack specific experience, following an established method can help the problem-solving process and ensure that you make appropriate considerations.

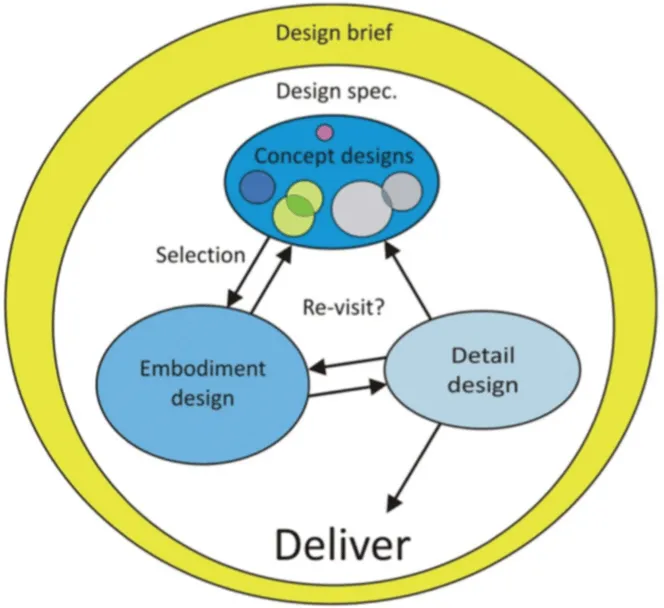

You can visualize the process, as shown in the illustration. This suggests that the design activities all occur within the requirements of the design brief and the design specification. When working at each stage you may acquire knowledge that suggests a change to the previous stage, so each stage can potentially feed back and require changes.

A simplified graphical representation of a design process.

Irrespective of any design methods applied, there is an immediate need to represent ideas in terms of form and function. These representations all help to develop a model of the design concept. This design model will be developed all the way through the process, ultimately ending up in a format that enables the parts to be made.

THE DESIGN MODEL

The design model is a representation of the design. The model can exist as anything from ideas, through to rough sketches and notes, calculations, sets of detailed formal engineering drawings, computer-generated 3D representations, to physical prototypes. CAD software products exist to help the designer to create and develop all these forms of the design model.

The design model is used by the designer to record and develop ideas and to provide a basis to evaluate the design. This is true for every stage of the design, from initial concept development through to the final detail design work. The design model is fundamental to the design process. Larger design projects are undertaken by more than one engineer, and design models are used to communicate and share ideas between all those concerned with the product design, development, manufacture and use.

So, whether working alone or as part of a team, a designer needs to have the skills to generate and work with the design model in order to develop and communicate an idea.

Designers use a variety of model types, depending on what property of the design is to be considered and for whom the information is destined. Typically the design model may represent information relating to the following:

♦ Shape (geometry, form, dimensional accuracy, tolerances)

♦ Appearance (aesthetics, material and surface finish visual effects)

♦ Function (behaviour, strength, stiffness, ergonomics)

♦ Manufacture (process-specific geometry)

There are CAD software products available that enable the modelling and documentation of all these aspects of the design. The next section aims to ...