eBook - ePub

Case Histories in Vibration Analysis and Metal Fatigue for the Practicing Engineer

Anthony Sofronas

This is a test

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Case Histories in Vibration Analysis and Metal Fatigue for the Practicing Engineer

Anthony Sofronas

Book details

Book preview

Table of contents

Citations

About This Book

This highly accessible book provides analytical methods and guidelines for solving vibration problems in industrial plants and demonstrates their practical use through case histories from the author's personal experience in the mechanical engineering industry. It takes a simple, analytical approach to the subject, placing emphasis on practical applicability over theory, and covers both fixed and rotating equipment, as well as pressure vessels. It is an ideal guide for readers with diverse experience, ranging from undergraduate students to mechanics and professional engineers.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Case Histories in Vibration Analysis and Metal Fatigue for the Practicing Engineer an online PDF/ePUB?

Yes, you can access Case Histories in Vibration Analysis and Metal Fatigue for the Practicing Engineer by Anthony Sofronas in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ingeniería industrial. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

Throughout my career I have been involved in many areas of mechanical engineering and machinery operation, as well as pressure vessel and piping problems. Any analysis was for the purpose of solving an actual problem that was occurring at the time. There usually wasn't time for a detailed study—an answer was required immediately so that equipment could be restarted safely and reliably with the most probable cause of failure having been determined. High-visibility failures, those drawing top management interest, usually required the attention of many experienced specialists. One discipline that I used to troubleshoot failures was vibration analysis, and over the years sufficient cases with known outcomes were developed that this book could be written. A notable focus is metal fatigue, because where there is excessive vibration, there is usually a fatigue-related problem. For the practicing engineer it is difficult to separate the two when a solution is needed to prevent a repeat failure.

Many books on vibration analysis are available. Some are heavy with theory and others are too simplified for practical everyday use. In this book I fill the void by using actual case histories to discuss the equations presented or the results shown, to heighten their usefulness for practical troubleshooting purposes. I do not consider specific vibration-measuring equipment or computer programs presently in use so that the book will be useful for a long time. The equations don't change much with time, only the methods used to solve them.

Nearly all machinery, pressure vessels, and piping systems will experience some vibration. In dealing with vibration concerns, the following questions are typically raised:

- What is causing the vibration?

- Is the vibration of sufficient magnitude that it needs to be controlled?

- How can the vibration be controlled?

Vibration-related problems occur less often than static stress-related failures such as bending, torsional, overload, or inadequate material properties. When severe vibration does occur, it can be very costly to remedy, sometimes requiring total system redesign. Vibration is the result of dynamic forces and moments acting on equipment. When severe enough, these can result in fatigue-related failures.

It is therefore important for those who design equipment or for users of the equipment to understand vibration and fatigue.

The book contains cases and information on problems in the petrochemical, component manufacturing, and transportation industries and encompasses over 45 years of personal experience. As such, it should be useful in many sectors of industry and also to those new to industry or new to vibration analysis. Many experienced engineers will also find problems and solutions that they haven't yet encountered.

The cases used are not based on developing new designs but on investigating the causes of failures or on troubleshooting newly installed, up-rated, or in-service equipment. New machinery, piping systems, and pressure vessel designs are usually based on the manufacturers' experience with the equipment, and reputable manufacturers use the latest analysis techniques available. It is only when a piece of equipment is the first one ever built, or the biggest ever built, that problems can occur. When large equipment is designed as simply a scale-up of a smaller design, things don't always scale up as hoped. Manufacturers may also use linear scale-up techniques on nonlinear problems, resulting in fatigue failures.

In a previous book of mine [1] many areas of mechanical engineering and their associated failures were examined using theory and case histories. In this book, only failures due to excessive vibration are considered. Since the book represents primarily my personal experiences, it does not cover all types of vibration. Excellent references are provided to supplement the information. The book does present vibration problems that engineers responsible for many types of equipment will encounter during their careers. Some of the work presented in this book has also been taught to personnel in various companies in seminar format and therefore contains input from many participants.

Most of the examples are simplified so that the reader doesn't have to have, or purchase, special software to solve many of the vibration problems that occur. The simplified solutions were enough to determine the cause of the vibration problem and implement a solution. I show the development of simplified equations when appropriate. In some cases simplification is not possible, and more complex software must be used. For example, torsional vibration of a multimass system driven by a gasoline or diesel engine can have many harmonics and can require specialized software for frequency and amplitude calculations. Engineers who send such work to a consulting firm should understand what is being done even if they aren't proficient in particular areas, as the results will need to be understood and explained to others.

Although exact solutions may not be possible with the simplified equations shown, in most cases they will allow the specialist to better understand the causes of the vibrations and to address them. Sometimes it will just indicate that a vibration consultant should be contacted and provides the specialist with information to discuss the problem intelligently with the consultant.

Many torsional vibration case histories are used in this book. There are two reasons for this. The first is that when a torsional vibration problem occurs in machinery, it is usually an expensive failure and not easily fixed. Calculations need to be expedited and solutions need to be practical. The second reason is that I have an extensive background in analyzing and testing design-related systems for torsional vibration. Thus, there were a considerable number of actual case histories. Most of the failure case histories have interesting stories associated with them, which in some sections are included.

It is difficult to identify a true vibration failure. For example, a shaft failure may be written up as a vibration failure since extreme vibrations were felt. In reality, a rub may have developed that caused bending loads which resulted in a fatigue failure. In this case, rotating bending was the true cause and vibration was a result, not the cause.

The total number of major failures examined during my 45 years in industry and consulting was approximately 400, which would be a total of 100% of the major failures examined. Only 20% were similar to those shown in this book and were defined as vibration problems. This is more typical than atypical for engineers dealing with failures in industry. Not all of an engineer's time is spent investigating vibration-related failures, but when these types of failures do occur they are usually major investigations. Most vibration alignment or balance problems are just annoying and can be eliminated with a quick realignment or field balance and don't result in a failure.

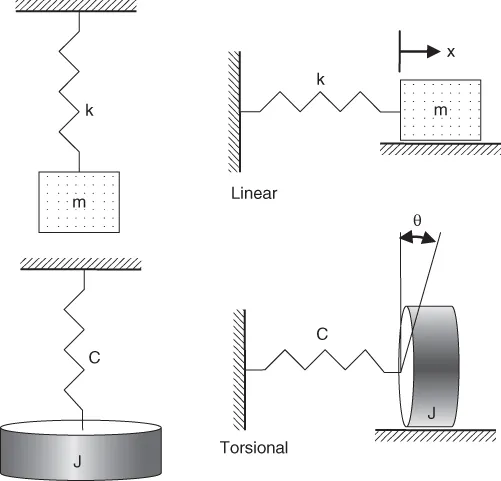

Before we begin it will be useful to describe briefly the two types of vibrations that are discussed in this book. The first are linear vibration systems, which in this book have units of in., lb, and sec, and the second are torsional systems, which have units of rad, in.-lb, and sec. Many of the problems are described as single-degree-of-freedom problems, those with one mass and one spring (Figure 1.1). If either is pulled (linear) or twisted (torsional) and released, they will vibrate at their natural frequency, which is fn = 9.55(k/m)1/2 cycles per minute (cpm) for the linear system and fn = 9.55(C/J)1/2 cpm for the torsional case. The similarity between the two equations comes in very handy for understanding vibration. Single-degree-of-freedom models are extremely useful, since many complex vibration systems can be reduced to them. They are much easier to understand and analyze and their results are much easier to explain to others, as is shown by the case histories in this book.

Figure 1.1 Linear and torsional vibration systems.

Even single-degree-of-freedom (SDF) models can become complex, as in the case of self-excited vibration, transient, or forced damped vibration problems. Most of the time they are useful because multi-degree-of-freedom problems or several masses with their attaching springs can be “lumped” to form a single mass–spring model. The first example in Chapter 2 shows this.

Also described are the variety of fatigue failures that can occur and that are typical for industry. The types discussed occur many times, and seeing actual photographs should help the specialist understand what may have caused the fatigue. Impacts that occur several times and cause a failure are not truly fatigue failures, which are usually thought of as representing a very high number of cycles. I once worked with an extremely talented and experienced mechanical engineer when I was just starting work in industry. This engineer said: “Everything fails in fatigue.” When I questioned his statement and asked him about a one-cycle impact failure, his remark was: “That's low-cycle fatigue.” His point was, of course, that most failures on machinery spinning at high speeds are usually fatigue related. With speeds and power increasing over time, these types of fatigue failures are becoming even more common.

Reference

1. Sofronas, A., Analytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case Studies, Wiley, Hoboken, NJ, 2006.

Chapter 2

Basics of Vibration

2.1 Spring–Mass Systems and Resonance

Vibration problems on compressors, motors, and ship systems can cause extensive damage. The key element of vibration problems is that many can be reduced to a very simple system for troubleshooting calculations. Although exact results cannot be expected, a better understanding of the problem can be.

We discuss vibrations here using case histories and describe the terms therein. There is a good reason for this, as many complex machines or structures can be reduced as described in the examples. This is especially true when modifications of existing equipment are being reviewed. This first case history is based on the vibration of a 2200-hp steam turbine that had a history of startup and in-service vibration problems. Although much vibration testing was done, this analysis looks at understanding the cause and explaining the nomenclature along the way.

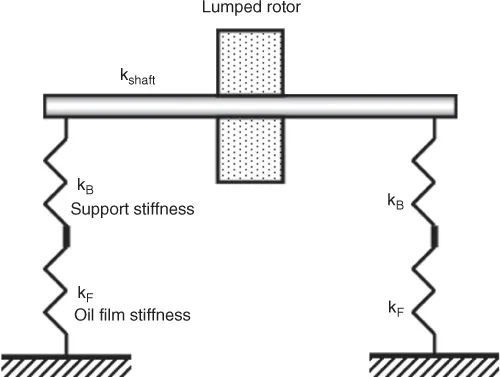

This fairly simple multistage steam turbine will be reduced to a simple system so that the fundamental natural frequency can be determined. The rotor is shown out of the turbine in Figure 2.1. Since at this time only the rotating members are of importance, the rotor disks can be combined into one mass, and the bearing supports and bearing oil film into springs, as shown in Figure 2.2.

Figure 2.1 Steam turbine rotor.

Figure 2.2 Simple steam turbine system.

The shaft can be represented as a simply supported beam and has a k value P/δ or a load divided by its deflection under the load. It can then...