Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance

Towards Zero Carbon Transportation

Richard Folkson

- 784 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance

Towards Zero Carbon Transportation

Richard Folkson

About This Book

Most vehicles run on fossil fuels, and this presents a major emissions problem as demand for fuel continues to increase. Alternative Fuels and Advanced Vehicle Technologies gives an overview of key developments in advanced fuels and vehicle technologies to improve the energy efficiency and environmental impact of the automotive sector.

Part I considers the role of alternative fuels such as electricity, alcohol, and hydrogen fuel cells, as well as advanced additives and oils, in environmentally sustainable transport. Part II explores methods of revising engine and vehicle design to improve environmental performance and fuel economy. It contains chapters on improvements in design, aerodynamics, combustion, and transmission. Finally, Part III outlines developments in electric and hybrid vehicle technologies, and provides an overview of the benefits and limitations of these vehicles in terms of their environmental impact, safety, cost, and design practicalities.

Alternative Fuels and Advanced Vehicle Technologies is a standard reference for professionals, engineers, and researchers in the automotive sector, as well as vehicle manufacturers, fuel system developers, and academics with an interest in this field.

- Provides a broad-ranging review of recent research into advanced fuels and vehicle technologies that will be instrumental in improving the energy efficiency and environmental impact of the automotive sector

- Reviews the development of alternative fuels, more efficient engines, and powertrain technologies, as well as hybrid and electric vehicle technologies

Frequently asked questions

Information

Introduction

Abstract:

1.1 Introduction

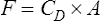

1.2 Technology roadmaps to deliver low carbon targets

1.3 Vehicle technology contributions to low carbon targets