Chapter 1. Introduction

Gasification is a chemical process that converts carbonaceous materials like biomass into useful convenient gaseous fuels or chemical feedstock. Pyrolysis, partial oxidation, and hydrogenation are related processes. Combustion also converts carbonaceous materials into product gases, but there are some important differences. For example, combustion product gas does not have useful heating value, but product gas from gasification does. Gasification packs energy into chemical bonds while combustion releases it. Gasification takes place in reducing (oxygen-deficient) environments requiring heat; combustion takes place in an oxidizing environment giving off heat.

The purpose of gasification or pyrolysis is not just energy conversion; production of chemical feedstock is also an important application. In fact, the first application of pyrolysis of wood into charcoal around 4000 B.C.E. was not for heating but for iron ore reduction. In modern days, gasification is not restricted to solid hydrocarbons. Its feedstock includes liquid or even gases to produce more useful fuels. Partial oxidation of methane gas is widely used in production of synthetic gas, or syngas, which is a mixture of H2 and CO.

Pyrolysis (see Chapter 3), the pioneer in the production of charcoal and the first transportable clean liquid fuel kerosene, produces liquid fuels from biomass. In recent times, gasification of heavy oil residues into syngas has gained popularity for the production of lighter hydrocarbons. Many large gasification plants are now dedicated to production of chemical feedstock from coal or other hydrocarbons. Hydrogenation, or hydrogasification, which involves adding hydrogen to carbon to produce fuel with a higher hydrogen-to-carbon (H/C) ratio, is also gaining popularity. Supercritical gasification (see Chapter 7), a new option for gasification of very wet biomass, is drawing growing interest.

This chapter introduces the subject of biomass gasification with a short description of its historical developments, its motivation, and its products. It also gives a brief introduction to the chemical reactions that are involved in gasification.

1.1. Historical Background

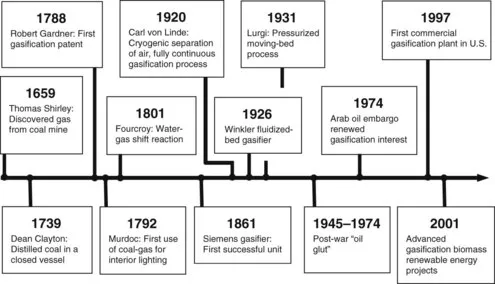

The earliest known investigation into gasification was carried out by Thomas Shirley, who in 1659 experimented with “carbureted hydrogen” (now called methane). Figure 1.1 shows some of the important milestones in the progression of gasification.

The pyrolysis of biomass to produce charcoal was perhaps the first large-scale application of a gasification-related process. When wood, owing to its overuse, became scarce toward the beginning of the eighteenth century, coke was produced from coal through pyrolysis, but the use of by-product gas from pyrolysis received little attention. Early developments were inspired primarily by the need for town gas for street lighting. The salient features of town gas from coal were demonstrated to the British Royal Society in 1733, but the scientists of the time saw no use for it. In 1798, William Murdoch used coal-gas (also known as town gas) to light the main building of the Soho Foundry, and in 1802 he presented a public display of gas lighting, astonishing the local population. Friedrich Winzer of Germany patented coal-gas lighting in 1804 (www.absoluteastronomy.com/topics/coal gas).

By 1823 numerous towns and cities throughout Britain were gas-lit. At the time, the cost of gas light was 75% less than that for oil lamps or candles, and this helped accelerate its development and deployment. By 1859, gas lighting had spread throughout Britain. It came to the United States probably in 1816, with Baltimore the first city to use it.

The history of gasification may be divided into four periods, as described in the following:

1850–1940: During this early stage, the gas made from coal was used mainly for lighting homes and streets and for heating. Lighting helped along the Industrial Revolution by extending working hours in factories, especially on short winter days. The invention of the electric bulb circa 1900 reduced the need for gas for lighting, but its use for heating and cooking continued. With the discovery of natural gas, the need for gasification of coal or biomass decreased. All major commercial gasification technologies (Winkler's fluidized-bed gasifier in 1926, Lurgi's pressurized moving-bed gasifier in 1931, and Koppers-Totzek's entrained-flow gasifier) made their debut during this period.

1940–1975: The period 1940–1975 saw gasification enter two fields of application as synthetic fuels: internal combustion and chemical synthesis into oil and other process chemicals. In the Second World War, Allied bombing of Nazi oil refineries and oil supply routes greatly diminished the crude oil supply that fueled Germany's massive war machinery. This forced Germany to synthesize oil from coal-gas using the Fischer-Tropsch (see Eq. 1.13) and Bergius processes (nC + (n + 1)H2 → CnH2n+2). Chemicals and aviation fuels were also produced from coal.

A large number of cars and trucks in Europe operated on coal or biomass gasified in onboard gasifiers. During this period over a million small gasifiers were built primarily for transportation (see Figure 1.2). The end of the Second...