![]()

Part One

Introduction to Compliant Mechanisms

![]()

1

Introduction to Compliant Mechanisms

Larry L. Howell

Brigham Young University, USA

1.1 What are Compliant Mechanisms?

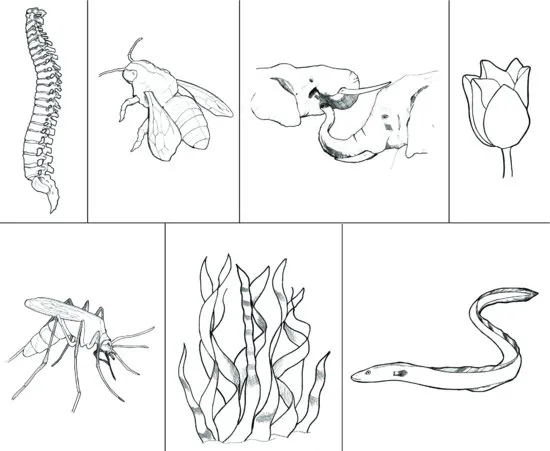

If something bends to do what it is meant to do, then it is compliant. If the flexibility that allows it to bend also helps it to accomplish something useful, then it is a compliant mechanism [1]. The idea of using compliant mechanisms in products is catching on, but traditionally when designers need a machine that moves, they commonly use very stiff or rigid parts that are connected with hinges (like a door on its hinge or a wheel on an axle) or sliding joints. But when we look at nature we see an entirely different idea from rigid parts connected at joints – most moving things in nature are very flexible instead of stiff, and the motion comes from bending the flexible parts [2]. For example, consider your heart – it is an amazing compliant mechanism that started working before you were born and will work all day every day for your entire life. Think of bee wings, elephant trunks, eels, sea weed, spines, and the blooming of flowers (Figure 1.1) – all of which are compliant. Even the natural motions that seem to be exceptions to this bending behavior, like your knee or elbow, use cartilage, tendons, and muscles to do their work. We see in nature the possibility of making machines that are very compact – a mosquito (Figure 1.1) is able to fly while carrying its own on-board navigation, control, energy harvesting, and reproduction systems. Would it be possible for us to improve human-designed products if we applied the lessons learned from nature and looked to flexibility to achieve movement?

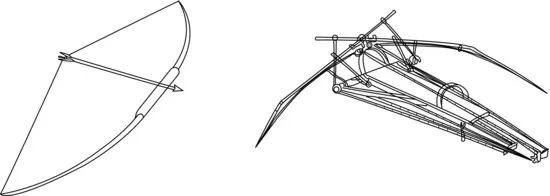

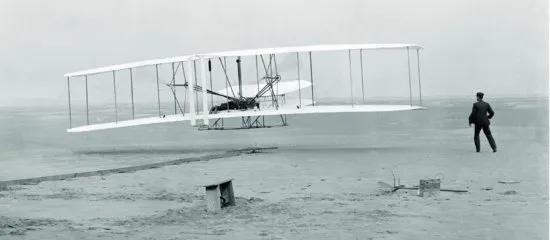

It is interesting that some early man-made machines were compliant mechanisms. Is that because we were closer to nature then? An example of a compliant mechanism with a multi-millennia history is the bow (Figure 1.2). Ancient bows were made using a composite of bone, wood, and tendon, and they used the flexibility of their limbs to store energy that would be released into propelling the arrow. It is interesting to see the sketches of Leonardo da Vinci [3] and see many compliant mechanisms (see Figure 1.2 for an example). Even one of the great achievements of engineering – sustained human flight – began with a compliant mechanism when the Wright brothers (Figure 1.3) used wing warping to achieve control of their early aircraft [4].

This may all sound good, but it turns out that compliant mechanisms can be difficult to design. Nature has done it, but nature employed very different design methods from those we mortals use. Great strides were made in the design of machines when compliance was left to nature and we moved to the much easier-to-design realm of rigid parts connected at hinges. For example, the too-sophisticated-for-its-time wing warping of the Wright Flier was eventually replaced by the much-easier-to-work-with control surfaces provided by an aileron pivoting on a hinge.

However, over the past few decades our knowledge has advanced. We have developed new materials, increased our computational capabilities and expanded the ability to design more sophisticated devices. At the same time, society has developed new needs that cannot be easily addressed using traditional mechanisms. This means that there is an increased ability to create compliant mechanisms, and an increased motivation for doing so. As an example, reconsider the example of aircraft control. The Wright Flier started out with wing warping for its control surfaces, but other aircraft quickly moved to approaches using traditional mechanisms. But with the increased computational power available and improved materials that have been developed, researchers are returning to the idea of wing warping to get the advantages, such as reduced weight, that would come from the approach.

One of the things that make traditional design of mechanical components compelling is that designers can separate different functions to be done by different parts, and each part is assigned to do that one function. The blessing and curse of compliant mechanisms is that they integrate different functions into fewer parts. Compliant mechanisms may be able to accomplish complex tasks with very few parts, but they can be much more difficult to design.

1.2 What are the Advantages of Compliant Mechanisms?

The integration of functions into fewer parts leads to compelling advantages for compliant mechanisms. For one, there is a potential for significantly lower costs. This comes from reduced assembly, fewer components to stock, and the possibility of simplified manufacturing (such as fabricating a mechanism from a single mold).

Another advantage is the potential for increased performance. This includes high precision [5,6] due to reduced wear and reduced or eliminated backlash. The low weight of compliant mechanisms can be useful for shipping and for weight-sensitive applications such as spacecraft. Eliminating the need for lubrication at joints is also a useful performance improvement that is helpful in many applications and environments.

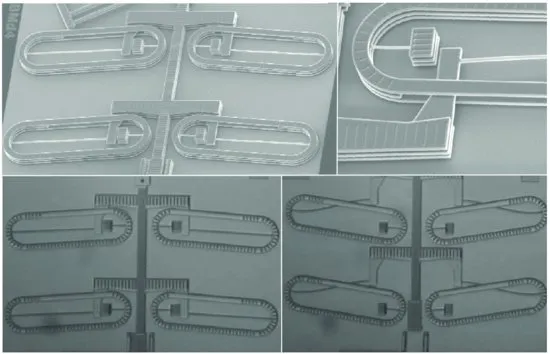

Another category of advantages lies in the ability to miniaturize compliant mechanisms. Microelectromechanical systems (MEMS) for example, are often fabricated from planar layers and compliant mechanisms offer a way to achieve motion with the extreme constraints caused by the resulting geometry (Figure 1.4) [7,8]. Compliant mechanisms will likely be central to the creation of nanoscale machines.

1.3 What Challenges do Compliant Mechanisms Introduce?

While the advantages of compliant mechanisms are amazing, they also have some challenges that have to be carefully considered in their design. For example, the integration of different functions into fewer parts offers advantages, but it also requires the simultaneous design for motion and force behavior. This difficulty is increased further by the fact that the deflections are often well into the nonlinear range and simplified linear equations are not adequate to define their motion.

Fatigue life needs to be addressed for most compliant mechanisms. Because their motion comes from bending of flexible parts, compliant mechanisms experience stress at those locations. When that motion is repeated during its life, fatigue loads are present and the fatigue life must exceed the expected life of the mechanism. Fortunately, methods for analyzing and testing fatigue life are available to help design compliant mechanisms for their needed fatigue life (see Chapter 2), but it requires special attention and effort to ensure that the mechanism has the life required.

Although properly designed and tested compliant mechanisms can achieve needed fatigue life, there can still be a consumer perception that flexible components are flimsy or weak. This can be a particular concern where the flexible component is visible to the consumer and it may require special care in the design for adequate life and for its appearance.

The motion of compliant mechanisms is often more limited than for traditional rigid-link mechanisms. For example, a shaft connected to bearings has the ability to undergo continuous revolution, whereas the motion of a flexible component will be limited by the deflection it can undergo before failure.

The fact that strain energy is stored in a deflected beam can be either an advantage or a disadvantage. Advantages include that a compliant element integrates both a spring and hinge function into a single component providing a “home” position where the device will go when unloaded. This integration also allows certain behaviors, such as bistability (the characteristic of having two distinct preferred positions, such as the on-off positions of a light switch) [9]. However, there are times when these qualities are not desired, and the properties become a disadvantage in the device design.

If certain materials are held under stress for long periods of time or at elevated temperatures, they can take on a new shape associated with the stressed position. This is called “stress relaxation.” Some compliant mechanisms have functions where they must maintain positions where they are under stress, and so are subject to stress relaxation conditions. This requires careful design and thoughtful choice of material.

1.4 Why are Compliant Mechanisms Becoming More Common?

Advances in our understanding of compliant mechanisms, combined with general technological developments, have resulted in a rapid growth in compliant mechanism applications (the library portion of this handbook is a testament to that growth). These applications range from high-end, high-precision devices to ultralow-cost packaging; from nanoscale featured components to large-scale machines; from weapons to healthcare products.

We mentioned that many early devices were compliant mechanisms, but then rigid-link devices connected at hinges gained favor because of the simplicity offered for analysis and design. So what is different now and why are there so many more compliant mechanisms than before? The answer lies at least partly in technological advances that have been made over recent decades. For example, new materials are available that are well suited for compliant mechanisms. There have been dramatic improvements in computational hardware and software available to analyze compliant mechanism motion and stresses. Developers and researchers have also increased our ability to design and analyze compliant mechanisms. Considerable effort has gone into creating methods to facilitate compliant mechanism design (some of the resulting methods are summarized in this handbook). There is also an increased awareness of the advantages of compliant mechanisms. As some commercial applications have been successful, they provide examples and inspiration for other applications to follow. Finally, as society and technology have advanced, new needs have risen, and some of these needs are best addressed by compliant mechanisms. This includes devices at very small size scales, devices with relatively complex motion but must be made at extremely low cost, compact medical implants, and high-precision machines.

1.5 What are the Fundamental Concepts that Help Us Understand Compliance?

There are a few straightforward but counterintuitive concepts that can help us understand the fundamentals of compliant mechanisms.

1.5.1 Stiffness and Strength are NOT the Same Thing

Usually when we want something to be strong (meaning that we don't want it to break), we also want it to be stiff (meaning that we don't want it to bend). For example, the floor in the upper story of a building we want to be both stiff and strong. We obviously don't want it to break, but we also don't want it to move around when people walk on it. So it needs to be stiff and strong. The crank shaft in an engine? Stiff and strong. A bridge? Stiff and stro...