eBook - ePub

Troubleshooting Vacuum Systems

Steam Turbine Surface Condensers and Refinery Vacuum Towers

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Troubleshooting Vacuum Systems

Steam Turbine Surface Condensers and Refinery Vacuum Towers

About this book

Vacuum systems are in wide spread use in the petrochemical plants, petroleum refineries and power generation plants. The existing texts on this subject are theoretical in nature and only deal with how the equipment functions when in good mechanical conditions, from the viewpoint of the equipment vendor. Also, the existing texts fail to consider the interaction of the vacuum system with the process equipment it serves and the variability of the motive steam conditions, change in cooling water temperature condenser fouling and erosion of the ejectors.

Here are some of the many questions answered in this groundbreaking volume:

- Why does my first stage jet make a surging sound during hot weather?

- Why does the vacuum suddenly break?

- I've seen moisture condensing on the jet's body! What's causing that?

- Why do I have to steam-out the drain legs from our condensers?

- Superheated steam is making our vacuum worse. Is this normal?

- How can I locate and measure air leaks?

- Reducing the steam pressure to my jets improves vacuum. But why?

- I can't pull the pre-condenser bundle. The shell side is fouling. What should I do?

- We're not getting our normal horsepower from our steam turbine. Could this be a jet problem?

- Raising the seal drum level improves vacuum! Is there an explanation for this?

- Our turbine exhaust steam pressure to our surface condenser has doubled in the last two years. What should we do?

- Restricting cooling water flow from our elevated condensers improves vacuum! Is this possible?

- What's a converging-diverging ejector all about?

- What's the difference between a barometric condenser and a surface condenser? Which is better?

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Troubleshooting Vacuum Systems by Norman P. Lieberman in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

1Chapter 1

How Jets Work

No sane person is going to read this book unless they are troubleshooting vacuum system problems for steam turbine surface condensers or process vacuum towers. It’s not a fun subject. As a matter of record, several of my closest colleagues have lapsed into insanity as a consequence of their interaction with ejectors, surface condensers, and seal drums.

I’ve never read a book, listened to a lecture, or seen a training video about vacuum systems. I have sometimes consulted vacuum system vendors, who have helped, but only up to a point. Still, my understanding as to how jets work is adequate for field troubleshooting.

1.1 The Converging-Diverging Ejector

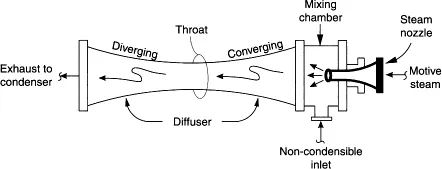

A converging-diverging ejector is a two stage compressor, but with no moving parts. I’ve shown a sketch of such a jet in Figure 1.1. If the jet has no moving parts, what is doing the work on the gas to compress it? The answer is the motive steam. And what property of the motive steam is doing the compression work? The answer is the velocity of the motive steam. This all has to be explained. It’s rather complicated, but I’ll make it simple for you.

Figure 1.1 Components of a converging-diverging steam jet.

You need to divide the ejector into three separate parts. I’ll describe each part separately. Then, afterwards we can worry about their interaction.

- Part One – The Steam Nozzle – The steam nozzle is really small. You can probably hold a large one in your hand. It’s much, much smaller in diameter than the steam supply line. It has a smooth, rounded opening. As steam expands through the steam nozzle, it accelerates from maybe 50 ft. per second in the supply line to perhaps 1,000 ft. per second at the discharge of the nozzle. The energy to accelerate the steam comes from two sources:

1. Some from the pressure of the steam

2. Most from the enthalpy (i.e., the heat of the steam)

I call the conversion of the steam pressure to kinetic energy, the Venturi Effect. This Venturi Effect is so efficient, that the pressure of the steam will drop as low as a few mm of Hg downstream of the nozzle in the mixing chamber (see Figure 1.1).

I call the conversion of the heat content of the steam to kinetic energy an Isoentropic Expansion. You can easily see what I mean. On your unit, check the temperature of the 150 psig (10 BAR) supply steam line. It’s about 360°F (182°C). Now, check the temperature of the mixing chamber (which the nozzle exhausts into). It’s about 90°F (assuming dry motive steam). What happened to the heat represented by the 270°F (360°F–90°F) cooling of the steam? That heat was converted to speed. That’s what Thermodynamics and the term, Isoentropic Expansion are all about:

- Thermo = Heat or Enthalpy

- Dynamics = Speed or Motion

- Part Two – The Converging Part of the Ejector – This is the half of the diffuser body that is downstream of the steam nozzle. It’s perhaps 100 times larger than the steam nozzle. It’s the front half of the diffuser shown in Figure 1.1. The motive steam enters the diffuser inlet at a velocity approaching sonic velocity or the speed of sound. The motive steam at this point already is combined with the off-gas from the vacuum tower or the upstream condenser vapor outlet. This off-gas has been drawn into the low pressure region of the mixing chamber created by the Venturi Effect of the motive steam.

The narrowing cross-section of the converging section of the diffuser causes the motive steam (including the off-gas) to accelerate. The combined vapor stream reaches, and then exceeds, the speed of sound at or before the diffuser’s narrowest section, called the throat. This is called critical flow or sonic velocity (see Figure 1.1).

As the flowing combined stream (i.e., steam plus gas) reaches sonic velocity, at or before the diffuser throat, it creates a pressure wave front which I’ll call the Sonic Boost. This will compress the vapors by a factor of perhaps three or four to one. However, if sonic velocity is not reached at or before the diffuser throat, then the sonic boost does not develop and the vapors are not compressed at all.

- Part Three – The Diverging Portion of the Ejector – This is the half of the diffuser body downstream of the diffuser throat. It’s the back half of the diffuser. The flowing vapors exit the throat into the gradually increasing cross-section of the diffuser. This causes the vapor to slow. The reduced kinetic energy of the vapor is converted into pressure. I call this the Velocity Boost. This will compress the vapor by a factor of about two or three to one. If the vapor velocity slows due to higher back pressure, this compression ratio is proportionally reduced.

The combined effect of the sonic boost multiplied by the velocity boost is the overall ejector compression ratio. I have seen ratios, though rarely, as high as 12/1. A more common compression ratio is about 8/1.

Loss of the Sonic Boost typically occurs for a wide variety of reasons, which is pretty much the subject of this book. When this happens, the ejector, which has been making a loud, roaring sound, will suddenly become much quieter. A sudden loss of vacuum will also result. The operators will then say, “The vacuum has broken.” At the Delaware City Refinery, where I’ve been working recently (see Chapter 3), when the vacuum would break, the vacuum tower top pressure would jump from 4 1/2 mm of Hg, to 10 or 12 mm Hg, and sometimes much, much more.

1.2 Interaction of Steam Nozzle with Converging-Diverging Diffuser

As the motive steam exhausts from the steam nozzle, it would be best for the steam to be moving at a maximum velocity. Since it’s the velocity of the steam that is compressing the vacuum tower or surface condenser off-gas, and not its pressure or temperature, it’s the velocity that always needs to be maximized. Malfunctions, such as erosion of the steam nozzle, hardness deposits in the nozzle, and low motive steam pressure will also reduce the nozzle exit velocity of the motive steam into the ejector’s mixing chamber, shown in Figure 1.1.

As the combined off-gas plus motive steam flows into the converging section of the diffuser, we would wish the vapor to be moving at a maximum velocity, so that we would be able to reach sonic velocity at or before the diffuser throat. If not, the sonic boost will be lost. Back pressure from the diverging portion of the diffuser, along with low diffuser inlet velocity, will both reduce the vapor velocity in the diffuser throat.

As the vapor flows through the diverging portion of the diffuser, we would wish the vapor to encounter the least back pressure from the downstream condenser. If the exhaust flow from the diffuser does encounter excessive back pressure, then the back pressure will be transmitted back into the diffuser throat. This will not have very much effect on the overall compression ratio of the ejector, unless the velocity in the diffuser throat falls below sonic velocity. Then the sonic boost is totally and suddenly lost and the pressure in the surface condenser or vacuum tower will jump in a most alarming manner.

The factors that normally cause excessive diffuser exhaust pressure are warmer cooling water flow to the downstream condenser, fouling of the condenser, condensate back-up from the seal legs or condensate pump, loss of the sonic boost in the downstream ejector, condenser problems on the discharge of the downstream ejector, air leaks on the body of the diffuser, as well as many other possible problems.

And then, on top of all the above problems that cause a loss in sonic boost, are motive steam problems, such as excessive steam superheat, excessive motive steam pressure, too low motive steam pressure, air leaks, entrained liquids, excessive cracked gas, frictional losses in inter-connecting piping, and, again, the possibility for many other problems (see Chapter 3).

The reader can now understand why I have said that this book will not be fun to read. But, if you’ve got a vacuum system problem, my book is about this very topic. You’re stuck with me. For better or worse, until success do we part.

1.3 Compression Ratio

When considering the performance of a vacuum jet, we must first consider the jet’s overall compression ratio. To calculate a jet’s compression ratio, use the following steps:

1. Measure the jet’s suction pressure and convert to millimeters of mercury, as explained in Chapter 2.

2. Measure the jet’s discharge pressure and convert to millimeters of mercury (mm Hg).

3. Divide the discharge by the suction pressure. This is the compression ratio.

It is not uncommon to find a proper jet developing an 8:1 ratio. More typically, jets will develop a 3:1 or 4:1 compression ratio. Any jet with less than a 2:1 compression ratio has some sort of really serious problem, but not necessarily with the jet itself.

1.4 Converging-Diverging Ejector

I’ll remind the reader that this is a two-stage compressor with no moving parts. The first stage of the compressor is the converging section. The second stage is the diverging section. Each section develops a separate compression ratio. By compression ratio, I mean the outlet pressure divided by the inlet pressure. For example:

- Compression ratio of converging section = 40 mm Hg ÷ 10 mm Hg = 4.0

- Compression ratio of diverging section = 100 mm Hg ÷ 40 mm Hg = 2.5

- Overall compression ratio = (4.0) • (2.5) = 10.0

(Note – The 40 mm Hg cannot actually be measured on a process jet.)

These are typical design values for a properly performing jet operating within its design parameters of vapor loads, discharge pressure, and optimum motive steam conditions. Rarely do I observe in the field any single steam jet developing a ten to one compression ratio. I’ve conducted pressure surveys on a thousand steam jets in commercial service. Perhaps one or two percent develop a compression ratio of more than seven or eight to one. At a Conoco-Phillips Chemical Plant in Cedar Bayou, Texas, I’ve observed a single, small ejector, run at a 12 to one compression ratio. So anything is possible!

Now, I’m going to explain in a slightly different way how jets work. The first component of steam jets, is the steam inlet nozzle, as shown in Figure 1.1. High pressure motive steam flows through a specially shaped nozzle. It will help to think about your garden hose. Assume you have 40 psig city water pressure in your hose. As the water escapes through the nozzle, the 40 psig water pressure is converted to velocity. The greater the pressure of the water in the hose, the greater the velocity of the water escaping from the nozzle.

As the high velocity steam enters the inlet of the diffuser, shown in Figure 1.1, it starts to compress the non-condensable vapor drawn into the mixing chamber. I have read in some books, that the motive steam “entrains” the non-condensibles. This is wrong. The non-condensible gas flows into the mixing chamber for the same reason that any gas flows into the suction of any compressor. It flows towards the inlet of the diffuser because gas flows from an area of higher pressure to an area of lower pressure.

The kinetic energy required to accelerate the motive steam to sonic velocity as it enters the diffuser inlet comes from:

- The pressure of the steam

- The temperature of the steam

- The latent heat of the steam

This means that as the motive steam escapes from the steam nozzle, it cools and also partly condenses. Thus, it is normal to have water droplets blowing into the diffuser.

As you can see from Figure 1.1, the cross-sectional area of the diffuser diminishes as it approaches the diffuser throat. This forces the vapor velocity to increase. Upstream of the diffuser throat, sonic velocity is supposed to be achieved. If this happens, the jet is said to be in critical flow. The flowing vapor has exceeded the speed of sound. This creates a pressure wave front that I call the “Sonic Boost.” It may compress the combination of flowing steam and non-condensables by a factor of four to one. To get the sonic boost, the velocity has to be above the speed of sound. As this velocity increases, the sonic boost compression ratio does not increase. However, if this velocity falls below the speed of sound, the sonic boost compression is instantly and totally lost. The converging section of the jet has stopped compressing the gas. The operators will say, “The Jet Has Broken,” and observe a precipitous loss in vacuum. If you were standing next to the jet at this point, it would start to make a much quieter sound, which you are sure to notice. Then it likely will begin surging or hunting. More on surging later.

1.5 Velocity Boost

As the vapors pass into the diverging portion of the ejector, shown in Figure 1.1, the cross-sectional area of the diffuser increases. The vapor slows down. The reduction in kinetic energy is converted to pressure. I call this conversion of velocity to pressure, “The Velocity Boost.” It may compress the combination of the flowing steam plus the non-condensables by a factor of two or three to one. The velocity boost is never entirely lost. It varies with steam pressure, and the vapor load and condenser back pressure. But it’s always compressing the gas to some extent. The velocity boost is essentially the second, and smaller stage, of a two-stage compressor, with no moving parts. When the jet “breaks”, the velocity boost continues working, even though the sonic boost has stopped completely.

Thermodynamics of Ejectors

Vacuum ejectors are two-stage compressors with no moving parts. The energy for both the first stage (sonic boost) and the second stage (velocity boost), comes from the kinetic energ...

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- Dedication

- Preface

- Introduction

- Definition of Terms

- Other Books by Author

- Chapter 1: How Jets Work

- Chapter 2: Making Field Measurements

- Chapter 3: Tabulation of Vacuum System Malfunctions

- Chapter 4: Effect of Water Partial Pressure on Jet Efficiency

- Chapter 5: Air Leaks

- Chapter 6: Sources and Disposal of Hydrocarbon Off-Gas

- Chapter 7: Motive Steam Conditions

- Chapter 8: Mechanical Defects of Ejectors

- Chapter 9: Condenser Fouling and Cleaning

- Chapter 10: Pressure Control of Vacuum Towers

- Chapter 11: Condenser Cooling Water Flow

- Chapter 12: Condensate Back-Up in Condensers

- Chapter 13: Seal Leg Drainage

- Chapter 14: Other Types of Vacuum Equipment

- Chapter 15: Air Baffle and Impingement Plate in Surface Condensers

- Chapter 16: Optimizing Vacuum Tower Operation

- Chapter 17: Frequently Asked Questions

- The Norm Lieberman DVD/Video Library of Troubleshooting Process Operations

- Index