- English

- ePUB (mobile friendly)

- Available on iOS & Android

Polymer Extrusion

About this book

Extrusion is by far the most important and the oldest processing and shaping method for thermoplastic polymers. This process concerns almost all synthetic polymers, as well as elastomers or food materials. Single-screw extrusion is mainly used nowadays to manufacture finished goods or semi-finished products. More than 90 million tons of thermoplastics are therefore processed every year.

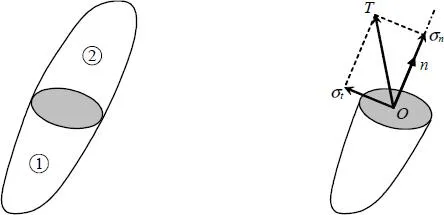

Twin-screw extrusion may be divided into two systems: contra-rotating systems used within the context of PVC extrusion, for the manufacture of pipes or profiles; and co-rotating systems experiencing nowadays a very significant development, because of their significant adaptability and flexibility, which enables the manufacture of specific materials (polymer alloys, thermoplastic elastomers, filled polymers, nanocomposites). Extrusion is carried out by passing molten polymer through a tool called die that will give the product its final shape (films and sheets, rolled products, and electric cables). Thanks to the design of dies, we obtain at the output a product with controlled dimensions, uniform speeds and homogeneous temperatures. The book will discuss the same production types, but only in the case of coextrusion flows, i.e. multilayer stratified products. First of all, we will present in this book the physics of the mechanisms at stake, then propose more or less complex models in order to describe these mechanisms and then go forward in the interpretation of results and the control of condition flows.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Continuum Mechanics, Rheology and Heat Transfer Overview

1.1. Continuum mechanics

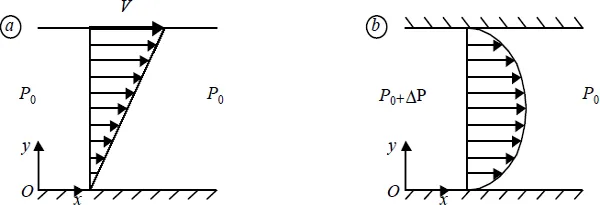

1.1.1. Strain

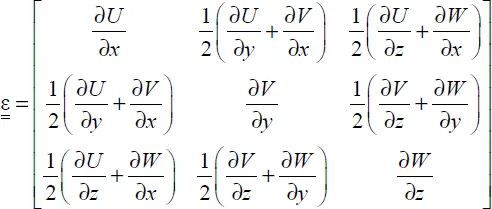

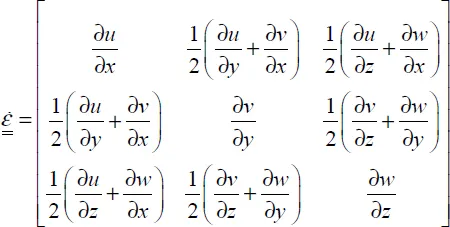

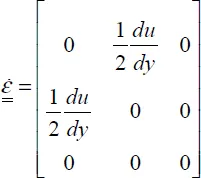

1.1.2. Strain rate

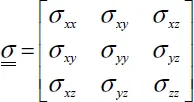

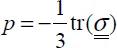

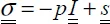

1.1.3. Stress

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright

- Introduction

- Chapter 1: Continuum Mechanics, Rheology and Heat Transfer Overview

- Chapter 2: Calculation Methods

- Chapter 3: Single-Screw Extrusion

- Chapter 4: Co-rotating Twin-Screw Extrusion

- Chapter 5: Profile Extrusion

- Chapter 6: Production of Films and Sheets

- Chapter 7: Wire Coating and Cable Insulation

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app