![]()

PART 1

FUNDAMENTAL ASPECTS

![]()

Chapter 1

Combinatorial Plasma-based Surface Modification of Polymers by Means of Plasma Printing with Gas-Carrying Plasma Stamps at Ambient Pressure

Alena Hinze1, Andrew Marchesseault2, Stephanus Büttgenbach2, Michael Thomas3 and Claus-Peter Klages1,3

1Technische Universität Braunschweig, Institut für Oberflächentechnik (IOT), Braunschweig, Germany

2Technische Universität Braunschweig, Institut für Mikrotechnik (IMT), Braunschweig, Germany

3Fraunhofer Institute for Surface Engineering and Thin Films IST, Braunschweig, Germany

Abstract

In this work a new method of achieving combinatorial area-selective modification of polymer surfaces is presented, utilizing atmospheric-pressure plasma printing with novel gas permeable electrodes. In these “plasma stamps” a microporous gas-carrying layer provides exchange of gaseous species from the gas stream to the individual microcavity discharges. Additionally, the electrodes can be fed with two (or more) different gases from spatially separate locations, allowing the generation of spot arrays with controlled gradients of physicochemical surface properties. Plasma-printed gradient surfaces can be used for combinatorial studies, for example in biomedical or polymer electronic research. In combination with spatially resolved surface characterization methods, the investigation of plasma-surface interaction processes can be significantly simplified. In the present contribution, gradient spot arrays were applied to optimize gas composition and functionalization parameters to provide optimal nucleation and growth of an electroless metal coating on a polymeric substrate. Locally plasma-modified surfaces were quantitatively characterized applying chemical derivatization (CD) followed by FTIR-ATR or SEM-EDX analyses in order to determine the area densities and spatial distributions of functional groups which are reactive towards the derivatization reagents used. Two chemical derivatization techniques were utilized: gas-phase derivatization (i) with 4-(trifluoromethyl)benzaldehyde (TFBA), forming a stable Schiff base with primary – but not secondary- amino groups, and (ii) with 4-(trifluoromethyl)phenyl isothiocyanate (TFMPITC) which is able to react with both primary and secondary amino groups forming thioureas, but – under the conditions used – not hydroxyl groups. It was, however, recently pointed out by us that other nitrogen-bearing functional groups such as imines can be captured by these methods as well.

Keywords: Dielectric barrier discharges, plasma printing, microplasmas, porous plasma stamps, polymer surface modification, gradient arrays, combinatorial plasma chemistry

1.1 Introduction

The term “plasma printing” stands for patterned surface modification or plasma-enhanced film deposition using ambient-pressure microplasmas enclosed in sub-millimeter sized cavities [1]. In early investigations, ceramic plates with laser- or mechanically drilled cylindrical through-holes covered by a fine metal mesh were used in order to allow diffusive gas exchange between the cavities and ambient. The mesh simultaneously served as one of two discharge electrodes, providing the electric field necessary to ignite a barrier discharge within the cavity. Using such an arrangement, the process gas can be transported by a stagnant flow and diffuse through the mesh into the cavities below it, enabling surface treatment with larger amounts of gas than available in the enclosed cavity volume. Different kinds of thin films with thicknesses up to several 100 nm have been deposited with arrangements of this kind [2, 3].

Producing more complicated patterns or larger arrays of regular vias in ceramic plates by laser-based or mechanical methods, however, is not trivial. Using free-standing insulator sheets for the definition of the plasma-printed areas, it is generally impossible to generate patterns in which the non-treated areas are not connected. In addition, a good mechanical contact between the plasma stamp and the substrate to be treated cannot be easily guaranteed because the application of uniformly distributed mechanical forces interferes with the provision of a stagnant gas flow over an area of several square centimeters.

For these reasons, recent work on plasma printing has focused on “plasma stamps” with closed cavities, produced by photolithographic techniques or by electromagnetic engraving [4] which were used for patterned plasma nitrogenation1 or plasma oxidation of polymer surfaces with lateral dimensions on the order of 100 μm or lower.

In order to make the patterned deposition of thicker coatings using plasma printing feasible, new solutions are required for the assembly of dimensionally stable plasma stamps that provide an exchange of gaseous species with the discharge in the cavity. Interesting opportunities are afforded by utilizing recent developments in the field of porous metallic materials, such as components with high permeability and porosity, which can be obtained from the sintering of metal fibers [6].

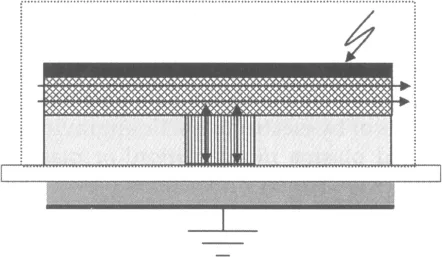

The principle of plasma stamps with a porous gas-carrying layer is illustrated in Figure 1.1. Compared with closed versions of plasma stamps the new design utilizing a microporous gas-carrying layer as an electrode offers a number of advantages:

- If surfaces shall not only be modified, like in the present paper, but when thin films beyond a few nm thickness are to be deposited, gas-carrying plasma stamps are a big advantage because virtually unlimited gas volumes can be fed into the micro-cavities and can be used for film formation.

- The cavities formed by the substrate and the stamp can be fed with the gas quite rapidly and very spa ringly. Oxygen traces in the cavities can be quickly displaced while getting around the necessity to provide an oxygen-free environment. This point is very important if polymer surfaces are to be plasma-nitrogenated because oxygen molecules compete with intermediate radical centers in this process [7].

- During the plasma treatment or coating of a surface, typically lasting a few seconds, a time-independent gas composition will be guaranteed due to the diffusive gas exchange between the microplasma in the cavities and the gas stream in the gas-carrying layer. Products of the process will be continuously swept away and a redeposition of plasma polymers will be suppressed.

- Last, but not least, plasma stamps with a gas-carrying layer based on a highly porous plate make new methods of combinatorial investigations of plasma-chemical surface modification processes possible and are very helpful for finding optimal process parameters.

Combinatorial methods in surface science and technology can be used to prepare “gradient surfaces,” i.e., surfaces with physicochemical property gradients which have recently received a lot of interest [8–10]. Gradient surfaces have a discrete or continuous spatial variation in physicochemical properties such as surface free energy, chemical composition and functional group densities or charge densities. A key benefit of gradient surfaces is that a small number of samples can be used to investigate the effect of variation of preparation parameters on many surface properties. The use of gradients significantly reduces time and improves the efficiency of R&D work. Gradient surfaces have been successfully used for combinatorial high-throughput studies in the search for new catalysts, semiconductors or superconductors and in biomedical or biomaterials research.

While combinatorial methods are well-established in chemistry and biochemistry systematic studies in plasma-based surface science are relatively rare and only in the recent years have several papers appeared on this topic, such as refs. [11, 12]. A method in which the movement of a substrate table was synchronized with a change in gas mixture being fed through an atmospheric-pressure plasma processor was published in 2004 [13]. The advantage of a method based on porous metal electrodes is that it can be made in a planar fashion and that the library of thin films compositions is generated in an area of only a few square centimetres, well-suited to surface analyses with physical methods, see below. For virtually every application in which the determination of optimum conditions for film deposition or surface modification by a plasma-based surface-technological process is necessary, combinatorial techniques can be used to drastically diminish the experimental effort.

An example of our current interest is the optimization of gas composition and deposition parameters to achieve optimal nucleation, growth and adhesion of electroless metal coatings on polymeric substrates [4], though many other applications are imaginable. Thus, the investigation of plasma-surface interaction processes in combination with spatially resolved surface characterization methods can be substantially simplified.

1.2 Experimental

1.2.1 Porous Plasma Stamp Design and Fabrication

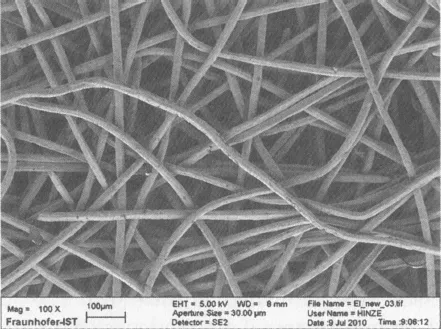

The heart of the novel plasma stamp is a 36 × 36 × 5 mm3 porous metal plate, manufactured by the sintering of Cr-Ni steel fibers (IFAM, Dresden, Germany) (see Figure 1.2). Steel fibers with a diameter of 27 μm were utilized in order to enable high gas permeability, with an open pore volume of about 84%, and still have a quasi-homogeneous global electric field distribution within the cavities.

As an electrode enclosure,...