![]()

Chapter 1

Industrial Challenges Where Computational Welding Mechanics Becomes an Engineering Tool

The welding process is intensively used in the nuclear industry as it ensures both material continuity and containment leak tightness. However, this joining process also leads to material modifications and induces permanent deformations and residual stresses at the macroscopic level with possible consequences on damage during welding operation or under operating conditions. Numerical simulations of welding processes were first performed at the beginning of the 1970s [MAR 74]. To meet nuclear regulation authorities’ requirements and because of the strongly increasing capabilities of computers, computational welding mechanics has been used more and more in engineering studies, taking multiphysics phenomena such as metallurgy into account [MAR 74, ALB 83, KAR 86, BER 91, GOL 92, DON 05, DHI 05]. Indeed, for a long time, numerical analyses of weldability have been slowed down by the metallurgical complexity of the considered materials and the necessity to determine the material behavior in the solid state at high temperatures and during solidification. However, concerning cold cracking issues, a phenomenological approach to estimate the risk of hydrogen-assisted cold cracking using the implant test modeling has early been proposed [LEB 88]. Later, these models have been completed to account for coupled viscoplasticity and transformation-induced plasticity during the welding of low-alloy steels [BER 03]. Today, for the prevention of damage, chained approaches can be used in spite of the difficulty to establish macroscopic fracture criteria in heterogeneous structures [ROB 09].

For manufacturing purposes, metallurgical weldability and distortions are the main issues. The former remains in the field of material science and the latter concerns solid mechanics. For design assessment of welded components under operating conditions, more attention is paid to welding residual stresses and strains. Indeed, stress corrosion cracking (SCC) can be activated due to the combination of metallurgical affectation, strain hardening and tensile stresses. Fatigue crack initiation can also be sped up by these consequences of welding and its propagation under high-cycle fatigue is directly driven by the mean stress sign and level. Brittle fracture and ductile tearing are other damages for which the thermo-mechanically affected zone (TMAZ) may become more sensitive due to embrittlement or toughness reduction.

These different issues (i.e. weldability, distortions and residual stresses) can be solved by mathematical modeling using the finite element (FE) method to compute coupled transient nonlinear problems. The following sections highlight industrial challenges for which computational welding mechanics has become a decision-making tool for welding and mechanical engineers.

1.1. Reducing the risk of weld cracking

1.1.1. Implant test modeling for risk of cold cracking assessment during welding operations

Filler material used for welding operations can lead to the occlusion of hydrogen gas in the arc atmosphere into the solidifying weld metal. This amount of hydrogen as well as that originally present in the parent metal rapidly diffuses into the various regions of the weldment due to the high temperature. Diffusion is also controlled by the microstructure evolution and trapping effects. As the welded component cools down, the risk of hydrogen-assisted cold cracking in ferritic steel can arise depending on the metal microstructure in the heat-affected zone (HAZ), the concentration of hydrogen in the weld and the level of residual stresses. One of the most effective precautions against weld hydrogen cracking is to use preheating and postheating in order to reduce the hydrogen content, by diffusion in the structure and degassing, before residual stresses reach higher values at the end of cooling. The implant test is a stress-controlled test applied on small specimens during welding to assess the susceptibility of the HAZ to hydrogen cracking. It may be used to define preheating temperature and postheating duration in order to prevent nuclear component assemblies from cold cracking risk. Finite element analysis (FEA) of the problem couples hydrogen diffusion, thermometallurgical and mechanical modeling as shown in Figure 1.1. The simulation of the implant test can be followed by local fracture analysis of the Weibull type. A probabilistic criterion can thus be used to assess the risk of cold cracking during welding operations on components made up of low-alloy steels such as A508cl3 according to the ASME code (or 16MND5 according to the RCCM French code).

Figure 1.1. Physical phenomena involved – couplings and interactions

1.1.1.1. Computation models

The interactions between heat transfer, metallurgy and mechanics have to be taken into account. As shown in Figure 1.1, strong coupling is performed to solve the thermometallurgical part and weak coupling is sufficient to predict mechanical states. Strong coupling means that temperatures and phase proportions are solved in the same system of equations unlike weak coupling that also concerns hydrogen diffusion and needs thermometallurgical and mechanical results as input data.

1.1.1.1.1. Heat transfer analysis

The heat transfer analysis is based on the solution of the classical heat equation with appropriate boundary conditions [BER 08, FEU 07]. It is computed on a threedimensional (3D) model in order to properly reproduce the thermal cycles in the heat-affected region. The shape of the heat sources and the input energy are fitted to experimental data (i.e. recordings of thermocouples and the dimensions of the weld pool and the HAZ obtained from macrograph transversal cuts). The precise description of the phenomena involved in the heat input such as arc-plasma interactions, and the analysis of fluid dynamics in the weld pool are not taken into account in the model. From the thermomechanical point of view, the fluid flow effect, which leads to homogenization of the temperature in the molten area, is simply taken into account by increasing the thermal conductivity over the fusion temperature.

As far as ferritic steels such as A508cl3 are concerned, phase transformations must be included in the simulation [DEN 97]. At each time step, a material is characterized by the proportions

pk of the different phases assuming that

From the modeling point of view, the phase proportions are additional state variables whose evolution can be described by ordinary differential equations on time [LEB 84a]. Material properties are both phase and temperature dependent. The thermal conductivity, the density and the enthalpy of the mixture of phases are calculated from individual phase values using a linear mixture rule. For single-pass welding processes, the following metallurgical transformations are modeled for the ferritic steel A508cl3:

– Initial base metal (mixture of ferrite and bainite) → austenite during heating.

– Austenite → (as-quenched) bainite during cooling.

– Austenite → (as-quenched) martensite during cooling.

1.1.1.1.2. Tempering

For temperatures lower than the austenitization temperature (Ac1 is approximately 700°C for A508cl3), tempering of as-quenched metallurgical structures also have to be taken into account. Tempering can be a consequence of multipass welding processes. It can also be the expected effect of postweld heat treatment (PWHT) or temper bead welding processes [LEB 84b]. Indeed, for metallic materials, at the end of manufacturing processes for which austenitization followed by fast cooling rates occurs, the subsequent as-quenched structure is acceptable regarding fracture toughness. For instance, the as-quenched-martensite presents a remarkably high mechanical strength but a rather low ductility. The tempering induced by a new welding thermal cycle or an appropriate heat treatment can balance these properties toward the expected values by:

– a suitable hardening precipitation in a zone where precipitates have been put in solution and the main alloy elements maintained in supersaturation;

– a softening of an excessively hardened structure.

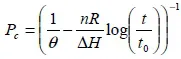

As for as-quenched transformations, tempering transformations from asquenched structures to fully tempered structures can be modeled using the same differential equations on time. Tempered phase proportions become new additional state variables associated with specific properties closer to the ones of the base metal. The parameters of kinetics of phase transformations during tempering have been identified in [VIN 02] within the framework of the characterization of the A508cl3 low-alloy steel for the numerical simulation of PWHT. The tempering equivalent parameter, Pc, between time and temperature, is used to identify the tempering kinetics during short thermal cycles related to welding processes. Pc is defined by the following relation [BLO 75]:

where θ is the temperature in Kelvin, t is the time, t0 is the time unit (generally equal to 1), n is the Naperian logarithm of 10, R is the constant of perfect gases and ΔH is the activation energy in joules per mole.

Figure 1.2. Evolution of the hardness in the HAZ during the deposit of several welding layers. For a color version of this figure, see www.iste.co.uk/bergheau/thermomechanical.zip

Figure 1.2 shows the tempering effect obtained during multipass welding in the HAZ of an A508cl3 ferritic steel plate using the modeling technique presented previously. The average hardness value obtained at the end of the fourth layer deposition is approximately 300 Vickers, much lower than the martensite hardness observed after the first bead deposit. Such a welding process, called temper bead, will be discussed in detail later.

1.1.1.1.3. Mechanical analysis...