![]()

Chapter 1

Everything is becoming science fiction

Place: Your life

Time: A few decades from now

. . . even in the future, it’s still hard to get up in the morning.

The smell of freshly baked whole wheat blueberry muffins wafts from the kitchen food printer. The cartridges to make these organic, low-sugar muffins were marketed as a luxury series. The recipes were downloaded from different featured artisan bakers from famous restaurants and resorts.

The first time you showed the food printer to your grandfather, he thought it was an automated bread machine—an appliance from the 1980s that took foodie kitchens by storm. He couldn’t understand why you wanted to print processed food until his anniversary came. To celebrate, you splurged on deluxe food cartridges and printed him and your grandmother a celebratory dinner of fresh tuna steaks, couscous and a wildly swirled chocolate-mocha-raspberry cream cake with a different picture within every slice.

Managing your diabetes has gotten easier since the health insurance company upgraded your food printer to a high-grade medical model. New medical-grade food printers for diabetics read streams of wireless signals from a tiny skin implant that tracks your blood sugar. When you wake up in the morning, the FoodFabber receives the first reading of the morning and adapts the sugar content and nutritional balance of your digitally cooked breakfast accordingly.

After breakfast, it’s time to check the news. The top story is an update on a rescue operation of several miners who have been trapped underground for a week. Their mine shaft collapsed, stranding them deep underground. At first rescue teams tried to dig them out until their shovels nearly triggered a deadly rubble slide.

Fortunately, the mining company followed federal safety regulations and properly equipped its miners with regulation safety gear. 3D safety printers are a standard tool that mining crews carry with them into deep mine shafts. Before they descend into the shaft, technicians make sure each printer has updated design files for every essential machine part that will go down into the mine. The 3D printer goes down with other machinery in case a part breaks and needs to be quickly replaced deep underground.

Today’s news update on the mining disaster reports that the portable safety printer has become an unlikely hero. For several days, the trapped miners have been conversing with above-ground technicians over a limping wireless connection. Both teams—one above and one underground—are working together to refine the printer’s design blueprints for the replacement parts.

What should have been a short, standard rescue operation has grown complicated. Just printing a few replacement parts would have been easy. The reason the rescue effort has been delayed is because the design for the broken part keeps buckling after it’s installed because of unexpected high levels of humidity inside the mine shaft.

The good news is that the situation in the mine looks brighter today. The reporter explains that the third attempt to print the replacement part passed its stress tests under simulated conditions at the mining company’s headquarters. Today the miners will print the updated design underground and, if that works, start rebuilding their damaged machine tonight.

As you leave your house for work, a crane and a lone construction worker toil silently on an empty lot across the street. Your neighbor’s construction project is the talk of the neighborhood. A few weeks ago your neighbor knocked down his old-fashioned wooden house to fabricate a new eco-friendly luxury home.

He waves from the mailbox and shows you the marketing brochure. The new home is a luxury model from a company called FoamHome and will be completed in two more weeks. FoamHome’s catalog explains that each home’s walls are constructed with built-in weather sensors. The roof, when it’s laid on top at the very end of the process, will contain solar panels. Walls will be fabricated with electrical wiring and copper pipes already in place.

Together you and your neighbor watch the construction crane slowly maneuver a gigantic nozzle over the top of the new foundation. The nozzle simultaneously scans the landscape and adapts the blueprint, as it squeezes out a paste made of a blend of cement and some synthetic building materials. The crew member’s job is to make sure no one walks on site during construction. The brains of the outfit is a small computer attached to the construction crane that guides the fabrication process.

The neighborhood has been watching the FoamHome project with great interest as the home’s walls slowly grow. What was that old joke about the early days of factory automation? “All you need these days to run a factory is a man and a dog. You need the man to feed the dog and the dog to bite the man if he tries to touch anything.”

So far, the slowly growing house looks gorgeous, its walls curved in organic patterns and soft curves and hollows. Nobody could build a house like this with frame carpentry, no matter how many people worked on the construction crew. No one has yet seen the inside of the new home, but rumor has it that your neighbor ordered designer inner walls that will look like they’re made of old-fashioned brick and mortar.

Finally you reach your office and catch up on the details of the final stages of a long investigation you’ve been leading for months. Your team was assigned to investigate a new sort of black market, one that deals in replacement body parts. More and more patients, desperate for replacement organs, are purchasing them from uncertified rogue bioprinting services rather than a certified medical provider. Bioprinting custom body parts continues to be a controversial topic in the public mind, more polarizing even than the stem cell, abortion, or cloning debates of your grandparents’ generation.

It’s gotten too easy to get replacement organs made. The cost of a high-res full body scan has plummeted in the past few years. People like to get them in their 20s and save the data for later, just in case if something goes wrong and they need a quick replacement organ. Sometimes it’s their joints that fail. In reality, the most common use of “body design files” is for cosmetic surgery, to recapture the tight wrinkle-free skin and body of youth.

Bioprinting isn’t the problem. In fact, most people believe that bioprinting is a life-saving technology. The challenge is what to do about the growth of these new black markets. Regulating the production of new printed body parts is difficult since the cost of bioprinters has also plummeted. Black marketeers snap up cast-off medical bioprinters for less than the price of a new car as last year’s bioprinter models are sold off each year by hospitals and surgical clinics.

During the investigation, you’ve learned that most of the time black market organs actually work pretty well. The problems arise from faulty design files or sloppy organ makers who cut corners and don’t use a sterile printing environment. In a recent case a few patients died from uncertified “vanity organs” they purchased to improve their athletic ability and appearance. Their families are trying to figure out who to sue: the rogue manufacturer, the bio-ink supplier, the organ designer, or the company that certified the design.

Black market bioprinters range from well-intended, would-be healers to deadly, profit-driven peddlers of rogue, counterfeit flesh. Some call the competent and hygienic black marketeers heroes for helping ill people obtain vital new organs at a lower price. Others deplore the organ merchants’ eagerness to profit from buying and selling essential tissue to vulnerable people, especially in cases where the new printed organ is poorly crafted.

At the end of the work day you stop by your daughter’s middle school. You’re one of the parental sponsors of this year’s Science Fair. Your daughter’s teacher tells you that 3D printers are disrupting the culture of the Science Fair. Lazy students 3D print elaborate objects with little effort and no skill—they just need to have a good design file. Many lower income students do not have home 3D printers so they aren’t getting the design time and practice they need for a level playing field.

There’s another twist. The teacher explains that for this year’s fair, parents will serve on a clean-up crew. Last year after the fair ended, the school’s custodians complained that the gym floor was littered with the debris of dozens of frenzied printing demonstrations. Even worse, for several days after the fair, students and teachers stumbled over dozens of mouse-sized, ready-made robots that clanked and rolled around school hallways. Some printed robots recited appropriate and preprogrammed bits of scientific lore. A few of the roaming robots, however, seemed to have mastered a few unauthorized and slightly more colorful bits of wisdom.

When you and your daughter get home, your spouse shares good news. His 3D printing manufacturing business just got accepted into an aerospace cloud manufacturing network. Cloud manufacturing is a new way to make things that’s starting to replace mass manufacturing. Cloud manufacturing—like cloud computing—is a decentralized and massively parallel model of production. Large companies order parts and services on demand from a vetted network of several small manufacturing businesses that have joined forces to manufacture specialized parts.

Cloud manufacturing is catching on quickly in the electronics, medical, and aerospace industries. These companies need complex, highly sophisticated parts, but not in huge batches. Clouds of small manufacturing companies save the big companies money. Cloud networks tend to be located near their clients so there’s less long-distance shipping of printed parts. The companies keep designs for product parts in digital inventory and make just one or a few at a time. Cloud manufacturing networks have been a boon for regional economies everywhere, creating local jobs in specialized small manufacturing and services companies.

Your spouse’s particular cloud consists of small companies that fabricate specialized fuel injector parts for military and commercial airplane manufacturers. To get into this particular network, his business had to demonstrate its manufacturing prowess by 3D printing sample airplane machine parts in a specified time frame. The manufacturing network stress-tested his sample parts and they performed well. After some negotiation on profit margins and manufacturing capacity, his business was admitted into the network.

Finally, the day winds down. Your son likes his bedtime routine in which he brushes his teeth and you tell him a story once he’s in bed. Tonight you discover that, as usual, his toothbrush has somehow gone missing. He thinks he may have left it at his friend’s house yesterday. You could run to the store to buy a new one, but there’s an easier way.

You boot up your home Fabber and let your son eagerly scroll through several different toothbrush designs. Several different companies sell designs on the Fabber but your son already knows he wants a zBrush—still a bargain at 99 cents. Your son likes the fact that there are several different cartoon figures offered for the toothbrush handle. You authorize his purchase and scan your son’s custom measurements—the size of his hand and shape of his open mouth—with a small wand attached to the Fabber.

The Fabber starts printing. On its glowing screen a list of design credits scrolls past that resembles those of a movie—from the designer of the toothbrush program to the company that owns the copyrights of the designs for the cartoon figures. The new toothbrush will be ready for use in 15 minutes.

As the Fabber prints you tell your son his bedtime story. It’s about the old days, one of those “when I was your age” tales. Your son listens skeptically. He has a hard time believing that when you were young, each toothbrush looked alike. If you ordered something from the Internet it took forever—24 hours—until it was delivered to the door.

“Wow,” he says politely. “Life must have been hard back then.”

![]()

Chapter 2

A machine that can make almost anything

What would you make if you had a machine that could make anything?

In England a technician scans the feet and ankles of Olympic sprinters and puts the data into a computer. The computer does a few quick calculations. The technician 3D prints new track shoes that are customized for each athlete’s unique body shape and weight, gait and tastes.

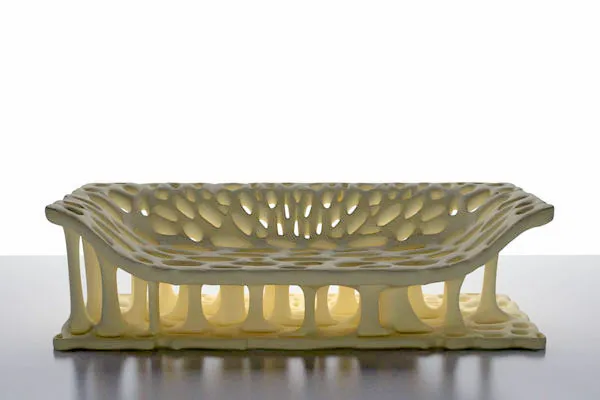

On the other side of the world, NASA test-drives a version of its Mars Rover in the Arizona desert. On board the Rover are several custom-made 3D printed metal parts. Many of these parts have complicated shapes made of curves and inner hollows that could not have been manufactured by anything other than a 3D printer.

In Japan, an expectant mother wants to create the ultimate commemoration of her first ultrasound. Her doctor edits her ultrasound image and 3D prints a precise, highly detailed replica of the fetus. The result, an avant-garde 3D printed plastic tribute to the tiny fetus, encased for posterity in a block of hard transparent plastic.

These modest manufacturing miracles are already taking place. In the not-so-distant future, people will 3D print living tissue, nutritionally calibrated food, and ready-made, fully assembled electronic components. This book is about a new way of making things. In the following chapters, we explain 3D printing technologies and design tools in simple language. For readers of a technical bent, a few chapters delve deeper into the details of 3D printing’s current and future. We then explore the downstream implications—economic, personal, and environmental.

3D printing opens up new frontiers. Manufacturing and business as usual will be disrupted as regular people gain access to power tools of design and production. Intellectual property law will be brought to its knees.

start figure end figure Some people remember exactly where they were when they watched the first moon landing. Others remember the confusing first weeks when the Berlin wall came tumbling down. I remember the first time I heard about 3D printing.

The time was the late 1980s. The place, a tedious engineering seminar on manufactu...