![]()

1

Project Management – Systems Engineering – the Industrialization Process

Enterprises have to adapt to a very changing world. They have to implement the decisions derived from their strategic analysis (see Chapter 4).

Over the past few decades, most enterprises, especially those in the Western world, have adopted a “project management” mode. Section 1.1 of this chapter will first define what a project is and then give some insights into project management. Sections 1.2 and 1.3 will cover systems engineering and the industrialization process, i.e. the set of processes needed to convert research and development (R&D) results into an industrial asset.

1.1. Projects and project management

1.1.1. Definitions

A project is a temporary activity with a beginning and an end, whose objective is to produce a unique result, a product or a service, called the scope of the project. A project is born and dies! A project is goal oriented. It can be:

– personal: lose weight, learn a foreign language, organize a trip, etc.;

– organizational: modify the IT system, hire an expert, acquire companies, set foot in some country, etc.;

– design a new product; build a bridge or a house, etc.

In the following, we deal mostly with physical or tangible projects, i.e. projects dealing with the creation of plants and industrial tools in general. A unique project can be repeated; a civil engineering company can be specialized in building bridges. Projects can vary largely in size and in cost from few thousand dollars to billions. They can be very simple like building a small storage tank or very complex. They may involve few people to many thousands. A project encompasses a certain number of tasks, which are the subdivisions of the project. These tasks are carried out in a rational way. For example, to build a house includes, among others, site preparation, constructing the walls, putting the roof up, etc. The roof cannot be installed before the walls are in place.

A work package is a group of tasks which can be performed by a specialized contractor, for example masonry, painting, electricity and others. Project management can be defined as precising what needs to be achieved – the project scope, putting in place (reuniting) human resources with various skills (the project team), finding financial resources, adequate equipment and materials, planning and controlling the work to keep it on track and reporting. Project management key success drivers are cost, quality and schedule.

Project management is not new! Building the pyramids in Egypt and the Eiffel tower in Paris required the utilization of project management techniques. However, project management took the shape it has today in the 1950s when the American administration launched a large number of programs of defense and space conquest; utilization of IT was decisive. A planning method like program evaluation and review technique (PERT) was developed by the US Navy for the Polaris missile project during that period. PERT is capable of planning and controlling a very large number of tasks.

Project management became an integral part of enterprise management, especially for enterprises working on a project to project basis, like civil engineering companies, professional congress organizers (PCOs) and engineering companies in general.

1.1.2. Project critical success factors

Project goal definition, i.e. the project scope, is well understood by all the project stakeholders (list of stakeholders has to be established). The project goal definition includes the following factors:

– project team organized with a project leader; an organization chart has to be outlined showing main functions, their relationship and names of people in charge;

– availability of adequate resources (human, financial, equipment, etc.);

– tasks definition with a planning;

– scope control in terms of cost, quality, schedule and management of change orders;

– project environment evaluation;

– risk management;

– management of crisis;

– overall project control via a steering committee;

– constraints assessment;

– adequate communication for the project team;

– reporting for the project stake holders on a timely basis;

– contracts of all kinds well defined upfront with contractors, customers, communities, raw materials suppliers, energy suppliers, etc.;

– respect of values (customers, contractors, country(ies), etc.);

– respect of regulations.

A project is considered successful when it is on time (i.e. schedule is met), on quality (i.e. expected performance is obtained within a specified period of time) and on budget (i.e. there is no budget overrun).

1.2. Systems engineering

Systems engineering finds its origin during World War II when the United States launched an unprecedented war effort and converted most of its industrial system, especially the car industry, to the manufacture of weapons. The Manhattan Project, the code name for an R&D project that manufactured atomic bombs, was a very complex engineering activity. NASA and the US Department of Defense’s very large and very complex projects were the reason for the development of systems engineering in the 1990s.

The International Council on Systems Engineering (INCOSE) was founded in 1990 by several US organizations.

Systems engineering can be defined as an interdisciplinary engineering discipline aimed at designing, realizing and managing systems successfully over their lifecycle. A system is successful if it satisfies customers’ and stakeholders’ needs, especially in terms of cost, quality and schedule.

Ludvig Von Bertalanffy (Vienna 1901–New York 1972) is considered to be the father of systems analysis.

There are many definitions of systems. We propose the following one [BEN 98b]:

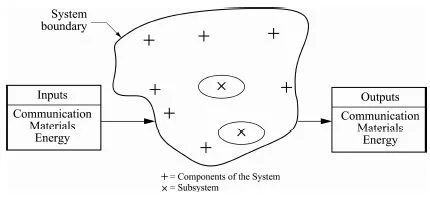

“A system is a set of interrelated components working together toward some common objective or purpose”. It is depicted in Figure 1.1.

Figure 1.1. Illustration of a system

It is clear from this figure that each component interacts with the others and impacts the system, and that the system has a boundary.

Let us take the case of a coal-fired steam generator. The system may include the coal storage, the burner, the demineralized water supply, the clinker system, the steam pipe, the stack, etc. The boundary may be extended to the coal supply by a barge, truck or train to the demineralized water process unit, to the steam piping system.

The boundary may be further extended to the total plant that uses the steam generated by the coal-fired generator.

One of the objectives of a system approach is to analyze its complexity. One component may be broken down into smaller components called subsystems. Let us take a highway. If the road itself can be considered as the main component, toll gates, gas stations, catering, patrol cars, information, etc., can be viewed as subsystems.

1.2.1. Systems classification

Some systems are considered as static, for example an office building is considered static from the civil engineering point of view. If we consider the same building during office hours, it becomes vibrant with people working, exchanging information, entering, leaving. It is considered as a dynamic system. Now, the building as a static system is aging as it is exposed to outside pollution, it needs heating, ventilation, air conditioning (HVAC); is it really static?

A system can be designed as closed if it does not exchange much with its environment. It can be a small village in the middle of nowhere or a sealed reactor where chemicals can react. On the contrary, a city like New York is obviously an open system as a huge amount of energy, food, information and money cross its boundary with large variations during the day and night.

Some systems are natural like a mountain, a river, a forest, whereas humanmade, technical systems are the result of human activity like an airport, a chemical plant, etc.

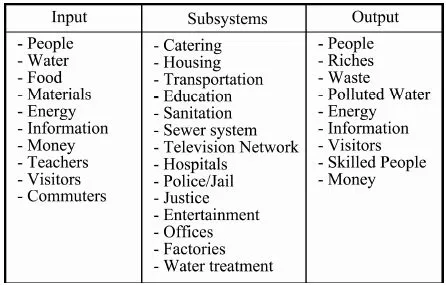

Systems that we live in become more and more complex due to human intervention. Each citizen depends on multiple systems for living, transportation, working, communication, health care, education, entertainment, etc. Table 1.1 illustrates a systemic analysis of a city; it is far from being complete.

Table 1.1. Systemic analysis of a Town

The following sections will focus on systems in use in the process industries, i.e. industries transforming materials and energy by chemical, physical or biological means. Systems engineering is a multi-disciplinary domain of chemical engineering.

1.3. The industrialization process

1.3.1. Definition: the industrialization steps

Industrialization can be defined as the set of processes that are required to move from research and studies to a production system, which is capable of delivering a product according to the predefined specifications and responds to a ...