Advanced Instrumentation and Computer I/O Design

Defined Accuracy Decision, Control, and Process Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Advanced Instrumentation and Computer I/O Design

Defined Accuracy Decision, Control, and Process Applications

About this book

Written by an expert in the field of instrumentation and measurement device design, this book employs comprehensive electronic device and circuit specifications to design custom defined-accuracy instrumentation and computer interfacing systems with definitive accountability to assist critical applications.

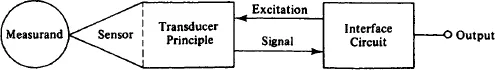

Advanced Instrumentation and Computer I/O Design, Second Edition begins by developing an understanding of sensor-amplifier-filter signal conditioning design methods, enabled by device and system mathematical models, to achieve conditioned signal accuracies of interest and follow-on computer data conversion and reconstruction functions. Providing complete automated system design analyses that employ the Analysis Suite computer-assisted engineering spreadsheet, the book then expands these performance accountability methods—coordinated with versatile and evolving hierarchical subprocesses and control architectures—to overcome difficult contemporary process automation challenges combining both quantitative and qualitative methods. It then concludes with a taxonomy of computer interfaces and standards including telemetry, virtual, and analytical instrumentation.

Advanced Instrumentation and Computer I/O Design, Second Edition offers:

- Updated chapters incorporating the latest electronic devices and system applications

- Improved accuracy of the design models between their theoretical derivations and actual measured results

- End-of-chapter problems based on actual industry, laboratory, and aerospace system designs

- Multiple real-world case studies performed for technology enterprises

- Instrumentation Analysis Suite for computer I/O system design

- A separate solutions manual

Written for international engineering practitioners who design and implement industrial process control systems, laboratory instrumentation, medical electronics, telecommunications, and embedded computer systems, this book will also prove useful for upper-undergraduate and graduate-level electrical engineering students.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

Thermal, Mechanical, Quantum, and Analytical Sensors

1-0 INTRODUCTION

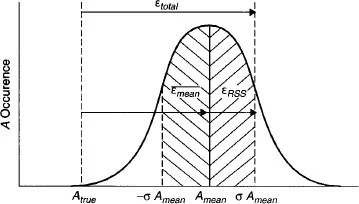

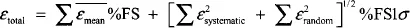

1-1 INSTRUMENTATION ERROR INTERPRETATION

| Accuracy: | The closeness with which a measurement approaches the true value of a measurand, usually expressed as a percent of full scale |

| Error: | The deviation of a measurement from the true value of a measurand, usually expressed as a percent of full scale |

| Tolerance: | Allowable deviation about a reference of interest |

| Precision: | An expression of a measurement over some span described by the number of significant figures available |

| Resolution: | An expression of the smallest quantity to which a quantity can be represented |

| Span: | An expression of the extent of a measurement between any two limits |

| Range: | An expression of the total extent of measurement values |

| Linearity: | Variation in the error of a measurement with respect to a specified span of the measurand |

| Repeatability: | Variation in the performance of the same measurement |

| Stability: | Variation in a measurement value with respect to a specified time interval |

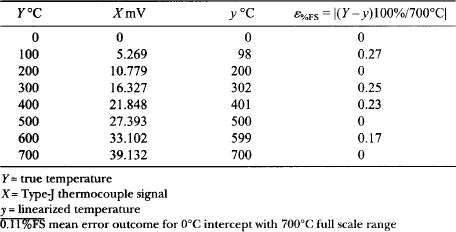

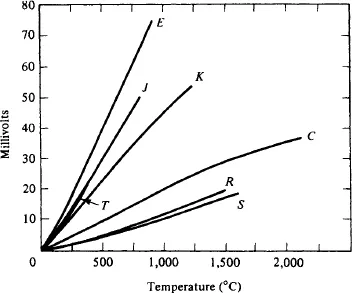

1-2 TEMPERATURE SENSORS

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- Preface

- Chapter 1: Thermal, Mechanical, Quantum, and Analytical Sensors

- Chapter 2: Instrumentation Amplifiers and Parameter Errors

- Chapter 3: Filters for Measurement Signals

- Chapter 4: Signal Conditioning Design and Instrumentation Errors

- Chapter 5: Data Converstion Devices and Parameters

- Chapter 6: Sampled Data and Reconstruction with Intersample Error

- Chapter 7: Instrumentation Analysis Suite, Error Propagation, Sensor Fusion, and Interfaces

- Chapter 8: Instrumented Processes Decision and Control

- Chapter 9: Process Automation Applications

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app