- English

- ePUB (mobile friendly)

- Available on iOS & Android

Materials and Surface Engineering in Tribology

About this book

This title is designed to provide a clear and comprehensive overview of tribology. The book introduces the notion of a surface in tribology where a solid surface is described from topographical, structural, mechanical, and energetic perspectives. It also describes the principal techniques used to characterize and analyze surfaces. The title then discusses what may be called the fundamentals of tribology by introducing and describing the concepts of adhesion, friction, wear, and lubrication. The book focuses on the materials used in tribology, introducing the major classes of materials used, either in their bulk states or as coatings, including both protective layers and other coatings used for decorative purposes. Of especial importance to the tribology community are sections that provide the latest information on Nanotribology, Wear, Lubrication, and Wear-Corrosion: Tribocorrosion and Erosion-Corrosion.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Surfaces

1.1. Introduction

1.2. The surface state

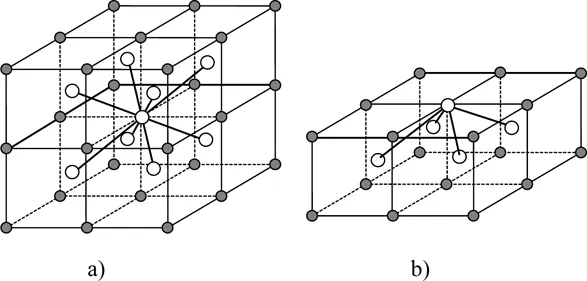

1.2.1. Structural state of a surface

Table of contents

- Cover

- Title Page

- Copyright

- Dedication

- Foreword

- Preface

- Chapter 1: Surfaces

- Chapter 2: Tribology

- Chapter 3: Materials for Tribology

- Bibliography

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app