![]()

Chapter 1

Introduction

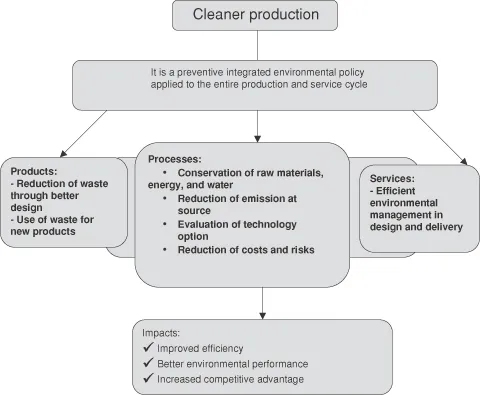

“Cleaner production” is an international term for reducing environmental impacts from processes, products, and services by using better management strategies, methods, and tools. It is a global movement for improving business performance and a profitable, cleaner, and sustainable future. According to the United Nations Environment Programme (UNEP) definition of “cleaner production” and the one in most common use is, “Cleaner production is the continuous application of an integrated preventive strategy to processes, products and services, to increase ecoefficiency and to reduce risks to humans and the environment” (AIT, 1999). A number of related terms are also used, including pollution prevention, low- or no-waste technologies, waste minimization, waste and emission prevention, source reduction, ecoefficiency, and environmentally sound technology. All these terms basically refer to the same concept of integrating pollution reduction into the production process and even the design of the product.

The meaning of the term “cleaner production” varies from the perspective in which it is used. For production processes, cleaner production involves conserving raw materials and energy, eliminating the use of toxic substances as much as possible, and reducing the quantity as well as the toxicity of all emissions and wastes before they leave any given process. For products, it means reducing their environmental impacts during the entire life cycle, from raw material extraction to ultimate disposal. For services, it means incorporating environmental concerns when designing and delivering services (Fig. 1.1).

The adoption of cleaner production in the industry leads to multifold advantages to an operating industry. Cleaner production leads to better efficiency of production, which means more output of products per unit input of raw materials. This helps in improving the financial performance of the mill. The ultimate goal of cleaner production is to minimize the generation of emissions and waste that needs to be treated and the associated costs. Given the increasing cost of raw materials and the growing scarcity of good-quality water, no industry can afford to use these resources inefficiently. Cleaner production measures help in overcoming constraints posed by scarce or ever-increasing costly raw materials, water, and energy.

Cleaner production minimizes the amount and toxicity of waste and emissions and renders products that are more agreeable from an environmental standpoint. The direct effect is that the pollution load on the environment is decreased and environmental quality is improved. It focuses on minimizing resource use and avoiding the creation of pollutants, rather than trying to manage pollutants after they have been created. It involves rethinking products, processes, and services to move toward sustainable development. Sustainable development concerns essential human activities, and sustainable development goals are often expected to dramatically affect both individual and public choices to modify production and consumption patterns (OECD, 2002; World Bank, 1998). Sustainable development is of critical importance for all citizens; it engages choices that will affect essential aspects of our lifestyles, and, being typically crosscutting, it should take into consideration various conflicting interests.

Consumers, suppliers, governments, and the market at large are increasingly demanding environmental responsibility by the business community. Businesses ignoring this trend and rejecting the opportunity to improve their environmental performance may find themselves left behind in the highly competitive global marketplace. Cleaner production is set to become an integral part of the business strategies of enlightened companies that want to embrace the ongoing challenges of industry leadership and continuous improvement. Cleaner production can reduce operating costs, improve profitability and worker safety, and reduce the environmental impact of our business. Companies are frequently surprised at the cost reductions achievable through the adoption of cleaner production techniques. Frequently, minimal or no capital expenditure is required to achieve worthwhile gains, with fast payback periods. Waste handling and charges, raw material usage, and insurance premiums can often be cut, along with potential risks.

On a broader scale, cleaner production can help alleviate the serious and increasing problems of air and water pollution, ozone depletion, global warming, landscape degradation, solid and liquid wastes, resource depletion, acidification of the natural and built environment, visual pollution, and reduced biodiversity.

It is proved from the past records that there lies a great potential for reduction in the pollution levels in the pulp and paper mills. From the different demonstration projects, it is established that adoption to the cleaner production has not only reduced the pollution loads but also helped in generating revenues by controlling the waste going down the drain (Nath, 1997; Radka, 1994; Satyanarayana et al., 2004).

The main difference between pollution control and cleaner production is one of timing. Pollution control is an after-the-event, “react and treat” approach, whereas cleaner production reflects a proactive, “anticipate and prevent” philosophy. Prevention is always better than cure. This does not mean, however, that “end-of-pipe” technologies will never be required. By using a cleaner production philosophy to tackle pollution and waste problems, the dependence on “end-of-pipe” solutions may be reduced or, in some cases, eliminated altogether.

Investing in cleaner production to prevent pollution and reduce resource consumption is more cost-effective than continuing to rely on the increasingly expensive “end-of-pipe” solutions. When cleaner production and pollution control options are carefully evaluated and compared, the cleaner production options are often more cost-effective overall. The initial investment for cleaner production options and for installing pollution control technologies may be similar, but the ongoing costs of pollution control technologies will generally be greater than those of cleaner production. Furthermore, the cleaner production option will generate savings through reduced costs of raw materials, energy, waste treatment, and regulatory compliance.

The environmental benefits of cleaner production can be translated into market opportunities for “greener” products. Companies that factor environmental considerations into the design stage of a product will be well placed to benefit from the marketing advantages of any future ecolabeling schemes.

Increasing consumer awareness of environmental issues has brought about a need for the companies to demonstrate the environmental friendliness of their products and manufacturing processes, particularly in international markets. By adopting the cleaner production approach, many of the market requirements are met and a company’s ability to compete and get access to the “green market” increases.

Cleaner production not only improves the environment outside the mill but also improves working conditions. Keeping the mill clean and free of waste, spilled water, and chemicals not only reduces the likelihood of accidents but also motivates the workforce to control new leaks and material losses.

As public awareness of the need for environmental protection is growing each day, it becomes more and more important for the industry to respond and react to the questions and demands posed by the public. The environmental profile of a company is an increasingly important part of its overall reputation. Adopting cleaner production is a proactive, positive measure and can help the concerned company build confidence in the public regarding its environmental responsibility. Some reasons to invest in cleaner production are

- Improvements to products and processes

- Savings on raw materials and energy, thus reducing production costs

- Increased competitiveness through the use of new and improved technologies

- Reduced concerns over environmental legislation

- Reduced liability associated with the treatment, storage, and disposal of hazardous wastes

- Improved health, safety, and morale of employees

- Improved the company’s image

- Reduced costs of end-of-pipe solutions

Cleaner production depends only partly on new or alternative technologies. It can also be achieved through improved management techniques, different work practices, and many other “soft” approaches. Cleaner production is as much about attitudes, approaches, and management as it is about technology. Cleaner production approaches are widely and readily available, and methodologies exist for its application. While it is true that cleaner production technologies do not yet exist for all industrial processes and products, it is estimated that more than 70% of all current wastes and emissions from industrial processes can be prevented at source by the use of technically sound and economically profitable procedures (Baas et al., 1992).

Cleaner production can contribute to sustainable development. Cleaner production can reduce or eliminate the need to trade off environmental protection against economic growth, occupational safety against productivity, and consumer safety against competition in international markets. Setting goals across a range of sustainability issues leads to win–win situations that benefit everyone. Cleaner production is such a win–win strategy—it protects the environment, the consumer, and the worker. It also improves industrial efficiency, profitability, and competitiveness.

Cleaner production can be especially beneficial to developing countries and those undergoing economic transition by planning, design, and management practices that facilitate innovative approaches to the reuse, remanufacturing, and recycling of the limited amounts of waste that cannot be avoided (Gavrilescu, 2004).

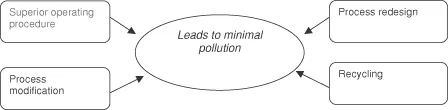

Cleaner production involves initiating steps to reduce the intensity of pollution at various levels. This can be accomplished by reducing the generation of wastes at its source and reusing and recycling the resources. Pollution prevention is of environmental and economic significance because it makes judicious use of the existing resources such as chemicals and water and eliminates the recurring costs involved in waste treatment and disposal. Most companies across the globe have charted out pollution prevention programs suitable to their industry requirements. Recent R&D initiatives undertaken by various companies include formaldehyde-free products, organic biocides, biotechnology products such as microbes, enzymes, and natural pigments.

Figure 1.2 shows the key initiatives taken by the pulp and paper industries to minimize pollution at various levels.

1.1 Superior Operating Procedures

The industry can implement changes in various departments such as the personnel department, inventory, waste handling department, and housekeeping units to ensure proper handling and storage of the wastes and monitoring the wastes for spills and leakages. Some of these include utilization of best available techniques such as minimizing the production of wastes and recycling of resources, separate storage and transportation facilities for nonhazardous from hazardous waste to facilitate recovery, reuse of certain chemicals and minimize the disposal costs, and conservation of water by recycling water within the industry and using the recycled water. Regular inspection of the machineries such as valves, pumps, and seals to detect leaks and spillages and the utilization of non-halogenated solvents and nontoxic cleaners during the cleaning of the machinery are required to eliminate the contamination of other materials in contact with the machinery.

1.2 Process Modifications

The existing operations can be modified to make industries more efficient and cost-effective, for example, inclusion of spill pits inside the plant to capture the leaking processed water and reusing this water in the process. About 20% of water wasted in the paper mills is due to spills, leakages, and washdowns; evaporation of black liquor to obtain concentrated solids; and modification of the system to support the usage of recycled paper in the manufacturing process.

1.3 Process Redesign

The paper and pulp process can be modified and redesigned to accommodate the economic and environmental concerns. A few of the improved designs include dry barking of wood instead of wet to minimize the utilization of water and sludge production, wet air oxidation of wastewater sludge to obtain filler material, elimination of chlorine as a bleaching agent by using alternate bleaching agents such as ozone, and selection of additives that do not form dioxins and furans.

1.4 Recycling

The paper industry now utilizes certain amount of waste materials as raw materials, especially recycled fibers. Some of the key recycling procedures are utilization of filters or strainers to recycle secondary fibers, recycling, and reuse of water, and solvents used for cleaning operations can be recycled.

Tables 1.1 and 1.2 present the features of cleaner production technologies and management practices. Cleaner production technologies are related to make different changes in the process by addition of some equipment in the production processes. On the other hand, cleaner production management practices will talk of enhancing cleaner production by measures such as housekeeping and maintenance practices. The management practices will also encompass the production culture in the plant, which affects the production wastes ...