![]()

CHAPTER 1

FUNDAMENTALS OF ELECTRIC POWER SYSTEMS

Xiao-Ping Zhang

1.1 INTRODUCTION OF ELECTRIC POWER SYSTEMS

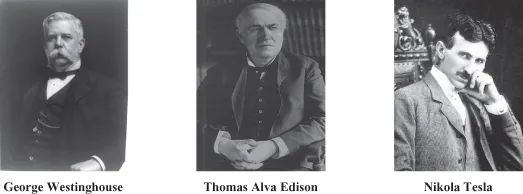

Commercial use of electricity began in the late 1870s when the inventive genius of Edison (Fig. 1.1) brought forth the electric incandescent light bulb. The first complete electric power system was the Pearl Street system in New York, which began operation in 1882 and was actually a DC system with a steam-driven DC generator. With the development of the transformer, polyphase systems, and AC transmission, the first three-phase line in North America was put into operation in 1893. It was then found that AC transmission with the help of transformers was preferable because DC transmission was impractical due to higher power losses.

With the development of electric power systems, interconnection of neighboring electric power systems leads to improved system security and economy. However, with the advent of interconnection of large-scale power systems, operation, control and planning of such systems become challenging tasks. With the development of digital computers and modern control techniques, automatic generation control (AGC) and voltage and reactive power control techniques have been introduced to operate and control modern large-scale power systems. Load flow solution has become the most frequently performed routine method of power network calculation, and can be used in power system planning, operational planning, operation control, and security analysis. With the advent of interconnected large-scale electric power systems, new dynamic phenomena, including transient stability, voltage stability, and low-frequency oscillations, have emerged. With the development of an electricity market, electricity companies engage in as many transactions in one hour as they once conducted in an entire day. Such increased load demand along with uncertainty of transactions will further strain electric power systems. Moreover, large amounts of decentralized renewable generation, in particular wind generation, connected with the network will result in further uncertainty of load and power flow distribution and impose additional strain on electric power system operation and control. It is a real challenge to ensure that the transmission system is flexible enough to meet new and less predictable supply and demand conditions in competitive electricity markets. FACTS (flexible AC transmission systems) devices are considered low-environmental-impact technologies and are a proven enabling solution for rapidly enhancing reliability and upgrading transmission capacity on a long-term cost-effective basis. FACTS can provide voltage regulation, congestion management, enhancement of transfer capability, fast control of power oscillations, voltage stability control, and fault ride-through. The ever-increasing frequency of blackouts seen in developed countries has increased the need for new power system control technologies such as FACTS devices. With the development of advanced technologies and operation concepts such as FACTS, high voltage DC (HVDC), wide area measurements, microgrid systems, smart metering, and demand-side management, the development of smart grids is underway. It has been recognized that SCADA/EMS Supervisory Control and Data Acquisition/Energy Management System plays a key role in the operating electricity networks and that state estimation is the key function of an EMS.

1.2 ELECTRIC POWER GENERATION

1.2.1 Conventional Power Plants

1.2.1.1 Fossil Fuel Power Plants

Basically, fossil fuel power plants burn fossil fuels such as coal, natural gas, or petroleum (oil) to produce electricity. Traditionally, fossil fuel power plants are designed for continuous operation and large-scale production, and they are considered one of the major electricity production sources. The basic production process of a fossil fuel power plant is that the heat energy of combustion is converted into mechanical energy via a prime mover, a steam or gas turbine, then the mechanical energy is further converted into electrical energy via an AC generator, a synchronous generator.

It should be mentioned that the by-products of power plant production such as carbon dioxide, water vapor, nitrogen, nitrous oxides, and sulfur oxides need to be considered in both the design and operation of the power plant. Some of these by-products are harmful to the environment. In dealing with this, clean coal technology can remove sulfur dioxide and reburn it, which can enhance both the efficiency and the environmental acceptability of coal extraction, preparation, and use.

In addition to coal, natural gas is considered another major source of electricity generation, using gas and steam turbines. It is well known that high efficiencies can be achieved by combining gas turbines with a steam turbine in the so-called combined cycle mode. Basically, natural gas generation is cleaner than other fossil fuel power plants using oil and coal, and hence produces less carbon dioxide per unit energy generated. It is worth mentioning that fuel cell technology may provide cleaner options for converting natural gas into electricity, though such a generation technology is still not competitive in terms of generation costs.

1.2.1.2 CCGT Power Plants

The combined cycle gas turbine (CCGT) process utilizes rotational energy produced from gas turbines driving AC generators as well as the additional power made available from the waste heat contained in the gas turbine exhaust. The heat is passed through a heat recovery steam generator, one for each gas turbine, and the steam generated is then used to produce rotational energy in a steam turbine driving a second AC generator.

For a thermal power station, high-pressure steam requires strong, bulky components and high temperatures require expensive alloys made from nickel or cobalt. Due to the physical limitation of the alloys, practical steam temperatures do not exceed 655 °C, while the lower temperature of a steam plant is determined by the boiling point of water. Considering these constraints, the maximum efficiency of a steam plant is between 35% and 42%.

In contrast, for a combined cycle power plant, the heat of the gas turbine’s exhaust can be used to generate steam driving a heat recovery steam generator with a steam temperature between 420 and 580 °C. This will in turn increase the CCGT plant thermal efficiency to 54%.

1.2.1.3 Nuclear Power Plants

Nuclear power technology extracts usable energy from atomic nuclei via controlled nuclear reactions and includes nuclear fission, nuclear fusion, and radioactive decay methods. Nuclear fission is the one most widely used for power generation today. The production process of a nuclear power plant is that nuclear reactors are used to heat water to produce steam, the steam is converted into mechanical energy via a turbine, and the mechanical energy can then be further converted into electrical energy via an AC generator, a synchronous generator. More than 15% of the world’s electricity comes from nuclear power, where nuclear electricity generation is nearly carbon-free. It is estimated that replacing a coal-fired power plant with a 1 GW nuclear power plant can avoid emission of 6–7 million tons of CO2 per year.

According to data from the International Energy Agency, existing nuclear power plants in operation worldwide have a total capacity of 370 GW. Most of them are second-generation light-water reactors (LWR) that were built in the 1970s and 1980s. Around 85% of the nuclear generation capacity is in US, France, Japan, Russia, the UK, Korea, and India. Third-generation nuclear power plant technology was developed in the 1990s to improve the safety and economics of nuclear power. However, due to the Chernobyl nuclear power accident in 1986, demand for constructing new nuclear power plants was much reduced and hence only a limited number of third-generation reactors have been ...