![]()

Chapter 1

Introduction – Electric Drive Components

1.1. Definition

An electric drive is a system providing an electromechanical conversion using an electric motor and including all the peripherals necessary for transmission, supply and control.

The concept of a system, in opposition to the motor only, is characteristic of the electric drive. The quality of this system is evaluated based on the weakest component.

The electric drive must be adapted to the application considered, using some of its components. The driven body (pump, machine tool, tracer, computer peripheral, robot, etc.), if it is not an integral part of the drive, determines its characteristics via the specifications which follow.

1.2. Electric drive components

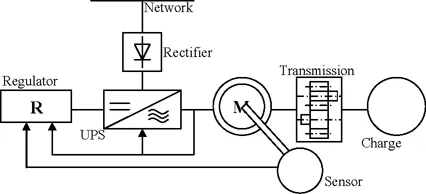

The main components of an electric drive are as follows (Figure 1.1):

– the transmission, which enables us to adapt the movement (rotating-linear conversion, for example), the speed, the resolution or the dynamics of the system;

– the electric motor, defined by its external characteristics and by regulation;

– the supply, which enables us to adapt the primary electric source to the motor;

– the command and the regulation which assure the control of the system dynamic behavior (positioning, speed, current, torque, etc.);

– one or several sensors which supply the information necessary for control;

– the safety and protection elements such as thermal protection, over-speed protections, overload, etc.

In a traditional way, each of these elements is designed individually, to enable the widest possible range of applications. The current trend goes towards the integration of some of these components into the motor (transmission, supply, sensor), while increasing the flexibility of use by means of a command with a programmable microprocessor.

The approach of a system analysis of electric drive involves, first of all, a study of components:

– the driven body which enables us to define the specifications and the constraints compulsory for the electric drive;

– the transmission which enables the adaptation of the electric drive to the load;

– the motor, its supply, its command and its peripherals which are strictly connected and conditioned by the desired function.

There are two steps when choosing synthesis:

– the weighting of the diverse choice criteria. Certain factors are a priority in an evident way, while others are more difficult to control. In particular, the economic aspects are strongly connected to specific conditions such as quantities, manufacturing etc., thus with more a priori known difficulty;

– the process of iteration enables a comparison of several variants, so as to make a considered choice that is put into perspective.

The following chapters will cover the analytical aspects, while the final chapters put the focus on synthesis.

![]()

Chapter 2

Driven Bodies

2.1. Function of the driven body

Any driven body is characterized by a function: pumping, position transfer, machining, oscillating movement, speed control, etc. The specifications objective is to translate this function into the terms of electric drive. Furthermore, a certain number of constraints, bound to the environment associated with the driven body, can intervene: primary electric source, atmosphere and ambient temperature, dimensional constraints (diameter, length, mass), etc.

2.2. Reference or rated running

Most electric drives can be characterized by the reference or rated running of the load. This corresponds to the torque that the system can permanently supply, without overheating any of its components. It is related to a reference speed ΩN. This reference speed is not the maximum possible speed. By rule and without particular precision, any drive has to withstand an over-speed of 20% of the rated speed.

Any rotating system is also characterized by a torque or a rated output with:

As per usual, motors are defined by their torque rates and their speed for the small powers; and by their rated output and their speed for the higher powers (1 kW approximately).

For many driven bodies, the power (or the torque) and the rated speed are clearly defined values: a pump is generally working at constant or weakly variable power and speed. On the other hand, for other driven systems, this concept has no sense a priori; only the transient behavior is characterized and the concepts of rated power and speed are only defined in an equivalent way, a posteriori.

2.3. Transient behavior

Transient behavior is defined by an evolution of one or several parameters in a duration lower than or comparable to the biggest time constant of the system. Very frequently, this last one corresponds to the thermal time constant of the motor. Two types of transient behavior are to be considered:

– an exceptional behavior, occurring in a periodicity clearly greater than the thermal time constant. Typically, start up, braking with recovery or a short-term overload are cases of an exceptional transient regime. Generally, it does not influence the design of the motor, instead influencing the design of some peripherals: electric supply, specific command, protection, etc;

– a reference behavior consisting of a succession of periodic transitory regimes such as acceleration, transfer with constant speed, deceleration, dead time. In a given configuration – transmission, supply, control defined – equivalent rated design can be deduced. The rated speed corresponds to the maximum speed. The rated equivalent torque is defined as the one which leads to the same losses, in permanent regime, as the average losses in transient regime.

A value characterizes an intermittent use of an electric drive: it is the rate of use that establishes the ratio between the switch on time and the reference duration, as a rule 300 s. Thi...