![]()

PART I

MEMBRANES AND APPLICATIONS IN WATER AND WASTEWATER

![]()

CHAPTER 1

Thin-Film Composite Membranes for Reverse Osmosis

TADAHIRO UEMURA and MASAHIRO HENMI

Global Environment Research Laboratories, Toray Industries Inc., Otsu Shiga, Japan

1.1 INTRODUCTION

Because of vastly expanding populations, increasing water demand, and the deterioration of water resource quality and quantity, water is going to be the most precious resource in the world. Thus, the 21st century is called the “water century.” In the 20th century, membrane technologies made great progress, and commercial markets have been spreading very rapidly and throughout the world. The key technologies fueling this progress are as follows:

1. Materials: Chemical design of high-performance materials suitable for each separation mode

2. Morphology: Morphological design of high-performance membranes

3. Element/Module: Element and module design for high-performance membranes

4. Membrane Process: Plant design and operation technology

In 21st century, to solve these water problems, membranes technology is going to be further expanded and new technology—further improvements of membrane performance, development of membrane systems, membranes stability such as antifouling membranes for wastewater treatment, and other highly qualified membranes—will be needed.

Among desalination technologies available today, reverse osmosis (RO) is regarded as the most economical desalination process. Therefore, RO membranes have played crucial roles in obtaining fresh water from nonconventional water resources such as seawater and wastewater.

1.2 APPLICATION OF RO MEMBRANES

Reverse osmosis membranes have been used widely for water treatment such as ultrapure water makeup, pure boiler water makeup in industrial fields, seawater and brackish water desalination in drinking water production, and wastewater treatment and reuse in industrial, agricultural, and indirect drinking water production as shown in Table 1.1.

TABLE 1.1 Application of Reverse Osmosis Membrane Process

|

| Ultrapure water, boiler water, process water, daily | Seawater desalination, pure brackish desalination | Industrial water, agricultural water water, indirect drinking water industries |

The expansion of RO membrane applications promoted the redesign of suitable membrane material to take into consideration chemical structure, membranes configuration, chemical stability, and ease of fabrication. And along with the improvements of the membranes, the applications are further developed.

1.3 MAJOR PROGRESS IN RO MEMBRANES

1.3.1 Cellulose Acetate Membrane

Reverse osmosis systems were originally presented by Reid in 1953. The first membrane, which could be used at the industrial level in actual water production plants, was a cellulose-acetate-based RO membrane invented by Loeb and Sourirajan in 1960. This membrane has a so-called asymmetric or anisotropic membrane structure having a very thin solute-rejecting active layer on a coarse supporting layer, as shown in Figure 1.1. The membrane is made from only one polymeric material, such as cellulose acetate, and made by the nonsolvent-induced phase separation method. After the invention by Loeb and Sourirajan, spiral-wound membranes elements using the cellulose acetate asymmetric flat-sheet membranes were developed and manufactured by several U.S. and Japanese companies. RO technologies have been on the market since around 1964 (Kurihara et al., 1987). They were widely used from the 1960s through the 1980s mainly for pure water makeup for industrial processes and ultrapure water production in semiconductor industries; and some are still used in some of these applications.

1.3.2 Aromatic Polyamide Hollow Fiber Membrane

Since then, there has been intensive and continuous R&D efforts mainly around the United States and Japan to meet the demands from commercial markets, and there exist many inventions and breakthroughs in membrane materials and configurations to improve the performances of membranes.

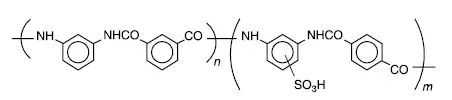

To overcome the problems of cellulose acetate membranes, many synthetic polymeric materials for reverse osmosis were proposed, but except for one material, none of them proved successful. The only one material, which could remain on the market, was the linear aromatic polyamide with pendant sulfonic acid groups, as shown in Figure 1.2. This material was proposed by DuPont, which fabricated very fine hollow fiber membranes; the modules of this membrane were designated B-9 and B-10. They have a high rejection performance, which can be used for single-stage seawater desalination. They were widely used for mainly seawater or brackish water desalination and recovery of valuable materials such as electric deposition paints, until DuPont withdrew them from the market in 2001.

1.3.3 Composite Membrane

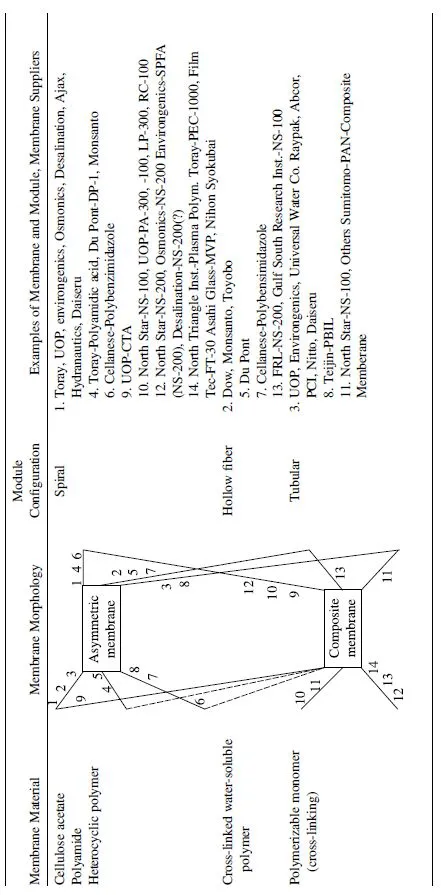

Another approach to obtain a high-performance RO membrane was investigated by some research institutes and companies in the 1970s. Many methods to prepare composite membranes have been proposed, as shown in Table 1.2. In the early stage, very thin films of a cellulose acetate (CA) polymer coating on a substrate, such as a porous cellulose nitrate substrate, was tried. However, in spite of their efforts, this approach did not succeed in industrial membranes manufacturing.

The next approach used the interfacial polycondensation reaction to form a very thin polymeric layer onto a substrate. Morgan first proposed this approach (Morgan, 1965), and then Scala et al. (1973) and Van Heuven (1976) actually applied this approach to obtain an RO membrane. But it was Cadotte who invented the high-performance membrane using the in situ interfacial condensation method (Cadotte, 1985). In his method, interfacial condensation reactions between polymeric polyamine and monomeric polyfunctional acid halides or isocyanates takes place on a substrate material to deposit a thin film barrier onto a substrate. Some of the composite membranes were succeeded in industrial fabrication by another method, which was designated as PA-300 or RC-100.

Another preparation method for composite membrane is an in situ monomer condensation method using the monomeric amine and monomeric acid halide, which was also invented by Cadotte. Then, many companies succeeded in developing composite membranes using this method, and the membrane performance has been drastically improved up to now. Now, composite membrane of cross-linked fully aromatic polyamide is regarded as the most popular and reliable material in the world. Permeate flow rate and its quality have been improved 10 times greater than that of the beginning (Kurihara et al., 1987, 1994b).

1.4 TRENDS IN RO MEMBRANE TECHNOLOGY

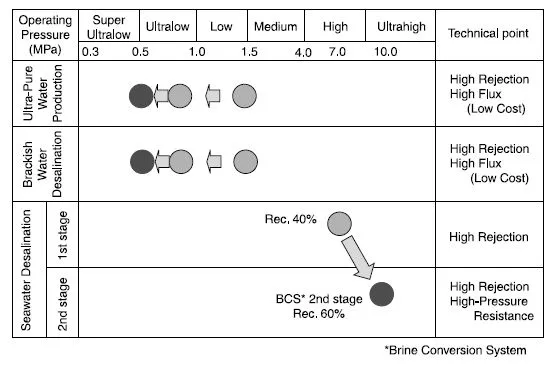

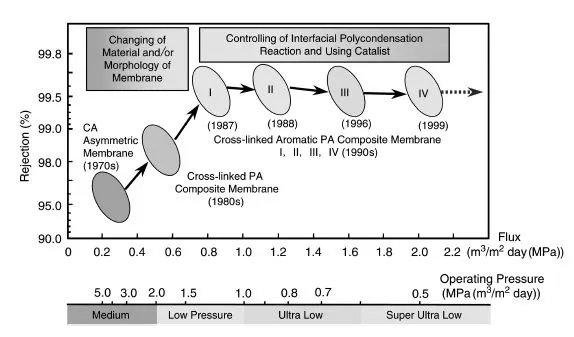

Figure 1.3 shows recent trends in RO membrane technology with two obvious tendencies. One is a tendency toward low-pressure membranes for operating energy reduction in the field of brackish water desalination. The other is a tendency toward high rejection with high-pressure resistance in the large seawater desalination market.

1.4.1 Progress of Low-Pressure Membrane Performance in Brackish Water Desalination

Figure 1.4 shows the progress of low-pressure membrane performance trends in RO membrane on brackish water desalination from the 1970s to the 1990s, including industrial water treatment such as ultrapure water production. In the 1970s much effort was devoted to developing high-performance membrane materials and improving the membrane performance. As a result performance was improved with a new developed material of cross-linked aromatic polyamide and by developing membrane morphology and fabrication technology. The cross-linked fully aromatic polyamide composite membrane developed in 1987 has four or five times larger water flux and five times higher product water quality than those of the CA membrane (Kurihara et al., 1987). Since 1987, membrane performance has been drastically developed. On the basis of the development of cross-linked fully aromatic polyamide composite membranes, RO membrane performance of brackish water desalination has improved very rapidly. Typical performances of the RO elements for brackish water desalination are shown in Table 1.3. The ultralow-pressure membrane, which can be used at ultralow pressures such as 0.75MPa, has been developed, which saves on the operating cost (Ikeda et al., 1996). And now the super-ultralow-pressure membrane elements, which can be used at super-ultralow-pressure, such as 0.5–0.3MPa, have been developed (Fusaoka, 1999). This membrane has three times the water permeability than the ordinary low-pressure RO membrane. This membrane can operate with onethird the pressure of a low-pressure membrane.

1.4.2 Progress of RO Membranes for Seawater Desalination

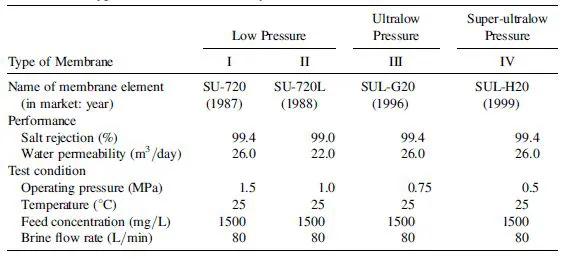

The progress of RO membranes for seawater desalination is shown in Figure 1.5 (Kurihara et al., 1994a). It is very important to increase the water recovery ratio on seawater desalination systems to achieve further cost reduction. Most seawater RO desalination systems in use today are confined to approximately 40% conversion of the feed water (salt concentration 3.5%), since most of commercially available RO membrane do not allow for high-pressure operation of more than around 7.0MPa.

Recent progress on high-pressure-high-rejection spiral wound (SW) RO elements, combined with proven and innovative energy recovery and pumping devices, has opened new possibilities to reduce investment and operating cost. The progress of RO seawater desalination from a point of view of water recovery is shown in Table 1.4 (Moch, 2000).

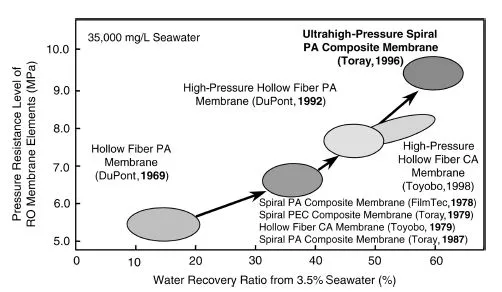

Toray has developed a new low-cost seawater desalination system called the Brine Conversion Two-Stage (BCS) system, as shown in Figure 1.6, which provides 60% water recovery of freshwater (Yamamura et al., 1996). Ohya et al. (1996) and Nakao (1996) also suggest that higher recovery of RO seawater desalination by the BCS system is most effective in saving energy yet keeping a low operating cost.

As for achieving the 60% RO seawater desalination system, it is absolutely necessary to make the RO membrane element, which can be operated under very severe operating conditions, with high pressure and high feed water concentration such as 9.0 MPa and 5.8%. Toray has developed a high-performance membrane (BCM element) that can be operated at high pressure and high concentration conditions, as shown in Table 1.5.

1.4.3 High Boron Rejection SWRO Membrane

The removal of boron is a significant problem in SWRO desalination processes (Fukunaga et al., 1997). Boron exists as boric acid in the natural water, and boric acid mainly shows the male reproductive tract when administered orally to laboratory animals. The World Health Organization (WHO) proposes that boron concentration in drinking water be below 0.5mg/L as a provisional guideline value (WHO, 2004). However, especially in SWRO desalination fields, this is not an easy goal to meet because boron concentration in seawater is comparatively high. Although conventional SWRO membrane elements have shown a little more than 90% of boron rejection, it is still inadequate. It is difficult for RO membranes to remove boric acid in water for the following reasons: First, the molecular size of boric acid is so small that it is difficult to remove by size exclusion. Second, since boric acid has a pKa of 9.14–9.25, it is not ionized in natural seawater with a pH of 7.0–8.0 and dissociates at pH 9 or more (Rodriguz et al., 2001). The boron rejection by the electric repulsive force between boric acid and the membrane cannot be expected in a neutral condition. Therefore, some posttreatment processes are necessary to meet the WHO proposal.

TABLE 1.4 Typical Performance of Toray’s Seawater RO Membranes

|

| Membrane material | Cross-linked fully aromatic polyamide |

| Membrane morphology | Composite membrane |

| Membrane substrate | Flat unwoven fabric | Unwoven fabric or taffeta |

| Feed water spacer | Special spacer | Normal spacer |

| Permeate spacer | Ultrahigh-pressure resistant | High-pressure resistant |

| Performance | | |

| Rejection (%) | 99.70 | 99.75 |

| Water permeability (m3/day) | 16.0 | 16.0 |

| Test condition | | |

| Feed concentration (mg/L) | 58,000 | 35,000 |

| Operating pressure (MPa) | 9.0 | 5.5 |

| Max. pressure (MPa) | 10.0 | 7.0 |

The conventional SWRO membrane element TM820, which is typical with Toray, has exhibited 91–93% boron rejection, which was the highest level achieved by commercialized SWRO membrane elements (Toray, 2004; Redondo et al., 2003; Hiro and Hirose, 2000). This membrane element series has been installed in a large number of SWRO plants. And Toray has commercialized many types of SWRO membrane elements, which are for different pressure ranges due to total dissolved solids (TDS) concentration and temperature of the seawater, as shown in Table 1.6. However, the highest boron rejection in those membrane elements is 91–93%, which is the s...