Chapter 1

The Toolbox

Tasks Performed in This Chapter

Basic tools for electronic construction The solderless breadboard Software tools and utilities To build anything, large or small, using the right tools makes a huge improvement in the quality of the finished product. The right tools will also speed up the process of building, minimize wasted materials, and reduce operator fatigue and stress. Sounds pretty important to have the right tools, doesn’t it? You’re right! This chapter shows you which, out of the zillions of tools, are the ones to use for building electronic circuits.

Basic Tools for Building Circuits

You’ll be pleasantly surprised to find that you don’t need a giant set of fancy tools to do excellent work! In fact, you may have most of them already and a couple of additional acquisitions are all that’s needed.

Mechanically speaking, you’ll need squeezers, cutters, turners, pokers, holders, and hole makers. That’s pretty simple, isn’t it? Of course, there is an incredible variety of available tools. I’ll list the basic items you really need, ways to upgrade them, and some optional tools that are handy but not necessities. Then you go shopping!

Buy the best tools you can afford — always! Then take care of them — always! With care, tools will last a literal lifetime. The author’s toolbox has perfectly functional and often-used tools that are 40 years old or more. Avoid bargain-bucket and no-name tools. An all-in-one tool is handy at times, but is no match for a single-purpose tool. Buy from a store with a no-questions-asked return policy that stands behind their tools. The selection of tools listed in this section has been made with electronics in mind, not robot assembly, plumbing installation, or home wiring. Tools for those jobs are often inappropriate for the smaller scale of electronics. Conversely, electronic tools are often overmatched for beefier work. There is no one-size-fits-all tool selection!

The Klein Company has specialized in tools for electrical and electronic work for decades. They have an excellent selection of tools designed for every possible use at the electronics workbench. Their online catalog (www.kleintools.com/ToolCatalog/index.html) is a great reference. Klein is my favorite, but there are many other fine tool companies. Ace Hardware has a comprehensive introduction to many common types of tools on their Web site at www.acehardware.com. Click ProjectsÍSolutionsÍLearning Guides to access the directory of informative pages. Safety and visibility

Before you head off to the hardware store with a big list, be sure that right at the top you include some basic safety equipment — goggles (or safety glasses), workspace ventilation (for soldering smoke or solvent fumes), and first aid. Electronics may sound tame, but the first time you snip a wire and hear the sharp end “ping” off your safety glasses or take them off and find a small solder “splat” right in front of your eye, you’ll be glad you had them on!

It sounds trite, but you really do need to be able to see what you’re doing! There are two paths to seeing your electronics clearly; lighting and magnification. Your workspace simply has to be brightly lit, preferably from more than one angle to minimize shadows. Inexpensive swing-arm laps with floodlight bulbs are good choices because they can be moved to put light where you need it.

Head-mounted magnifiers are inexpensive and lightweight. The Carson MV-23 dual-power magnifier (www.carsonoptical.com/Magnifiers/Hands%20Free) is widely available and provides both x2 and x3 magnification. Swing-arm magnifiers, such as the Alvin ML100 (www.alvinco.com), can be positioned in front of your face and provide additional illumination, too. Magnifiers are often found at craft and sewing stores for considerably less cost than at office or technical-supply stores.

Pliers and tweezers

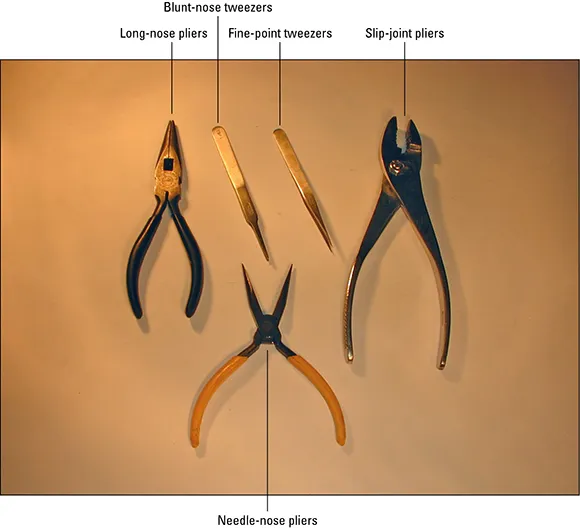

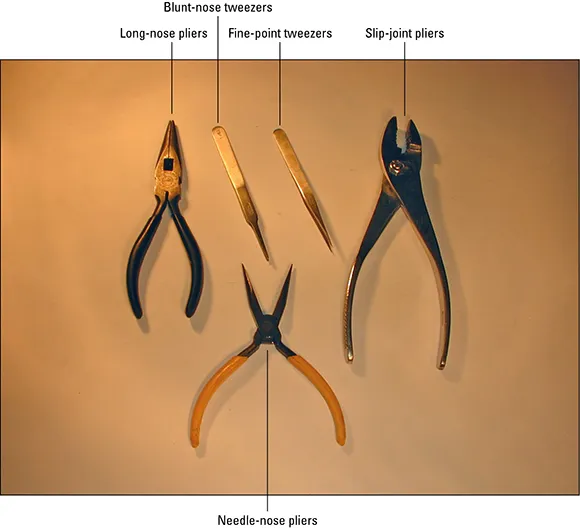

In the “squeezer” category are pliers and tweezers. The largest electronic thing you are likely to have to grab with pliers is a half-inch nut; the smallest will be tiny set screws. Pliers and tweezers that fit things in that range are good to have in your toolkit. Figure 1-1 shows a few examples of the pliers and tweezers that I use a lot.

The most common type of pliers are slip-joint pliers (8”) which have jaws that can be adjusted to grip large or small things. A small pair of locking pliers (6”) (optional) — also known as Vise-Grips™, come in very handy when working with connectors and can be used as an impromptu clamp or vise.

Needle-nose pliers (a generic term that covers many different styles of pliers) with serrated jaws are a necessity. You’ll need a heavy pair of combination long-nose pliers (8”–9”, with or without a side cutter) for bending and holding. Smaller needle-nose pliers (5”–6”) will be used for positioning and holding delicate components. Additional pliers with extra-fine jaws (or bent-nose pliers) are nice to have in the toolbox, but not required.

Figure 1-1: This set of pliers and tweezers will grab anything you’re likely to encounter in electronics.

Tweezers are absolutely necessary when working with surface-mount devices (see Chapter 4) and small mechanical assemblies. They should be made of stainless steel; you’ll need a pair with a blunt nose and a pair with pointed tips. Do not use regular bathroom or cosmetic tweezers — they’re not really designed for electronics jobs.

Cutters and knives

Two pairs of wire cutters will suffice. For heavy wire, coaxial, and data cable, you’ll need a pair of heavy-duty diagonal cutters (6”) like those in Figure 1-2. Get a pair with comfortable handles so that when you squeeze really hard you won’t...