- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Guidelines for the Management of Change for Process Safety provides guidance on the implementation of effective and efficient Management of Change (MOC) procedures, which can be applied to improve process safety. In addition to introducing MOC systems, the book describes how to design an initial system from scratch, including the scope of the system and the applications over a plant life cycle and the boundaries and overlaps with other process safety management systems.

Note: CD-ROM/DVD and other supplementary materials are not included as part of eBook file.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Guidelines for the Management of Change for Process Safety by in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

11

INTRODUCTION

Management of change (MOC) is a process for evaluating and controlling modifications to facility design, operation, organization, or activities – prior to implementation – to make certain that no new hazards are introduced and that the risk of existing hazards to employees, the public, or the environment is not unknowingly increased.

MOC is one of the most important elements of a process safety management (PSM) system. Changes occur when modifications are made to the operation or when replacement equipment does not meet the design specification of the equipment it is replacing. Other, more subtle changes can occur when new chemical suppliers are selected, National Fire Protection Association hazard classifications change, procedures are modified, or site staffing and/or company organization is revised. Such changes, if not carefully controlled, can increase the risk of process operation and result in incidents.

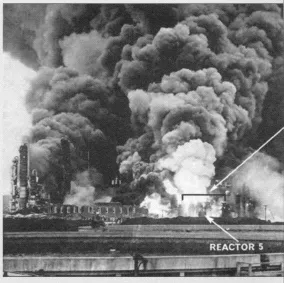

MOC has been called the minute-by-minute risk assessment control system in plants and companies. The significance of MOC – or the lack of it – was never more apparent than in the Flixborough accident, as shown in Figure 1.1.1 This watershed event involved a temporary modification to piping between cyclohexane oxidation reactors. In an effort to maintain production, a temporary bypass line was installed when the fifth of a series of six reactors was removed at a facility in Flixborough, England, in March of 1974. The bypass failed while the plant was being restarted after unrelated repairs on June 1, 1974, releasing about 60,000 pounds of hot process material, composed mostly of cyclohexane. The resulting vapor cloud exploded, yielding an energy release equivalent to about 15 tons of TNT. The explosion completely destroyed the plant, and damaged nearby homes and businesses, killing 28 employees, and injuring 89 employees and neighbors.

FIGURE 1.1 Flixborough Accident — Failure to Manage Change

No engineering support was available in the plant at the time of the accident. The temporary modification was constructed by people who did not know how to design large pipes equipped with bellows. As stated in the official report: “…they did not know that they did not know. ” An effective MOC system should have discovered the design flaw before the change was implemented, thus averting the disaster.

1.1 HISTORICAL PERSPECTIVE

Many companies have implemented MOC systems over the past 15 years. In 1989, the Center for Chemical Process Safety (CCPS) published its groundbreaking Guidelines for Technical Management of Chemical Process Safety, which included MOC as an element.2 However, most of the initial chemical industry MOC implementation activity has been driven by two forces: (1) the Occupational Safety and Health Administration’s (OSHA’s) PSM standard and (2) quality initiatives.3,4

In 1993, the Chemical Manufacturers Association, now known as the American Chemistry Council (ACC), published the first comprehensive guidelines on MOC: A Manager’s Guide to Implementing and Improving Management of Change Systems.5 However, this treatise was not widely distributed. Since that time, many conference presentations have been given, journal papers written, and several additional texts completed on MOC; and yet the industry “thirst” for effective MOC practices remains.6-7 More than ever before, companies recognize that insufficient control of changes plays a major role in accidents.

In addition, much has happened in the chemical industry since 1989 and a large amount of experience (good and bad) has been accumulated. Table 1.1 lists a number of events, happenings, trends, and experiences that CCPS considered as inputs to the development this book.

Given this industry experience, CCPS has developed these MOC Guidelines considering CCPS’s new Risk Based Process Safety (RBPS) system approach (Chapter 2).8 Table 1.2 lists the goals of these MOC Guidelines in serving identified industry needs.

As a result, companies can use these guidelines for any of the following activities:

- Implementing a company’s first MOC system

- Diagnosing and correcting a defective MOC system

- Determining ways to continuously improve MOC effectiveness

1.2 MANAGEMENT OF CHANGE ELEMENT OVERVIEW

MOC reviews are performed at operating sites or in company corporate offices that are involved with capital project design and planning. MOC reviews focus on bona fide changes, not replacements-in-kind (RIKs). An employee first originates a change request. Then qualified personnel, normally independent of the MOC originator, review the request to identify any potentially adverse impacts. Based on this review, and after addressing any additional requirements, a responsible party either approves or rejects the change for execution. If the change is approved, it can be implemented. Before startup of the change, potentially affected personnel are either informed of the change or provided with more detailed training, if needed. Affected process safety information (PSI) is modified to reflect the change. Most of the time, these activities are completed prior to startup of the change.

TABLE 1.1. Things that Have Happened in MOC Since 1992

| • More than 15 years of MOC experience, particularly with incidents for which failure of MOC was identified as a root cause |

| • Major increase in the use of electronic documentation of site information |

| • Emergence of MOC software applications |

| • Emergence of Web-based documentation sharing systems |

| • Company-wide MOC systems (involvement of non-local personnel in MOC reviews) |

| • Redistribution of PSM work to sites (lack of central monitoring of PSM/MOC) |

| • Downsizing and integration of MOC duties within production jobs |

| • Increased efforts to monitor MOC implementation via management reviews |

| • Organizational upheaval (divestitures, acquisitions lack of culture integration) |

| • Use of MOC in process areas not covered by regulatory standards |

| • Realization of the need for MOC for nontraditional types of changes |

| • PSM regulatory creep (broadening of the application for new change types and expanding the MOC work required) |

| • Expansion of the six-sigma approach and other productivity improvement initiatives, which has increased the workload associated with MOC systems involving subtle types of changes |

| • Accident investigations that have revealed the risk significance of previously under-considered sources of subtle change, such as organizational changes |

TABLE 1.2. Goals of these MOC Guidelines

| • Reduce the number of MOC related incidents and PSM audit findings |

| • Expand MOC into the process/project life cycle and nontraditional types of changes |

| • Tailor MOC systems to the facility size, perceived risk anticipated usage rate of the MOC system, and safety culture |

| • Monitor MOC performance at sites from afar, in real time, and cost effectively |

| • Quickly diagnose MOC problems without having to perform or wait for a PSM audit |

| • Make MOC systems more fault tolerant and resistant to circumvention or human error |

| • Monitor MOC performance and efficiency in a practical way |

| • Achieve better MOC results with fewer resources, if possible |

The main product of an MOC system is a properly reviewed change request that is authorized, amended, or rejected. Ancillary products include modified PSI, change communication, and updated training records.

Companies and sites usually have written MOC procedures that apply to all work that is not judged to be an RIK. The results of the review process are typically documented on an MOC review form. Backup information provided to aid the review or generated by the review is usually kept for several years as a foundation for updates and process hazard analysis (PHA) revalidations. This information also provides an auditable record of the MOC implementation process.

1.3 MOTIVATIONS FOR MOC

Companies that manufacture, handle, store, or use hazardous chemicals are committed to effective MOC for a variety of reasons. In addition to a desire to promote employee and public safety and to protect the environment, motivations for MOC include the intent to comply with (1) ACC’s Responsible Care® initiative, (2) government regulations requiring MOC systems, and (3) quality/environmental initiatives such as International Organization for Standardization (ISO) 9000/14000.3,5, 9-12

PSM practices and formal management systems have been in place in many companies for more than 20 years. PSM is widely credited for perceived reductions in major accident risk and improved chemical industry performance. Nevertheless, many companies continue to be challenged by resource pressures, inadequate management systems (as evidenced by chronic deficiencies found in MOC audit results), and stagnant process safety incident performance, particularly involving MOC systems.

1.3.1 Internal Motivations

Inappropriate changes can affect employee and/or public safety, damage the environment, or result in significant business interruptions. They can also reduce product quality or increase production costs. The desire to decrease the occurrence of change-induced incidents and reduce the cost of doing business motivates companies to create effective MOC systems that will enable them to remain competitive, grow, and prosper.

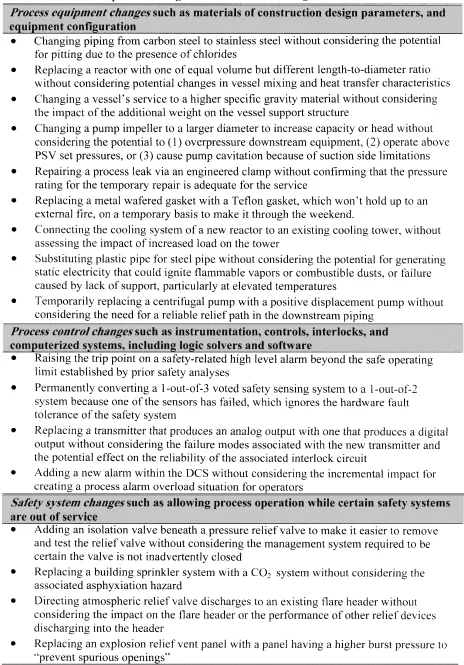

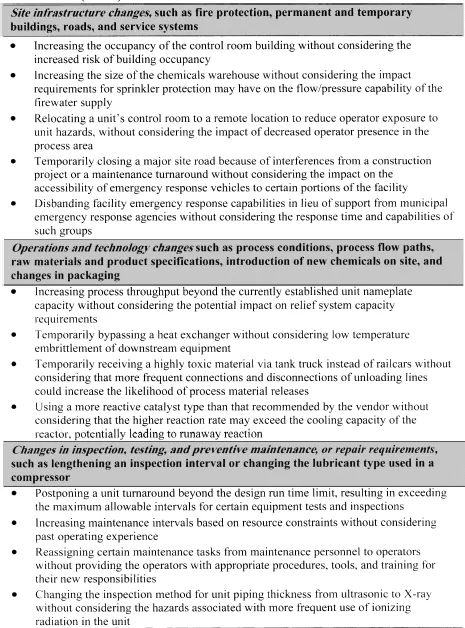

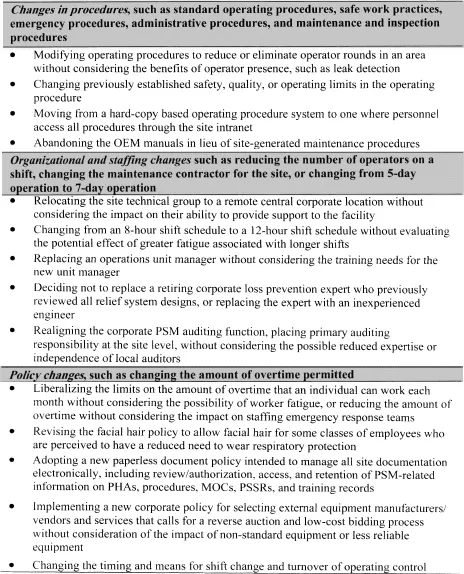

Experience has demonstrated that inadvertent, unintended, erroneous, or poorly performed changes – changes whose risk is not properly understood – can result in catastrophic fires, explosions, or toxic releases. The 1974 explosion at Flixborough, England, described at the beginning of this chapter, was fundamental to the development of formal safety management systems, both in Europe and the United States. Table 1.3 gives examples of changes that could increase risk.

MOC systems call for implementation of formal administrative procedures that require reviews and approvals of proposed changes within designated areas of a site. The objective of MOC is to prevent changes in process chemistry and technology, equipment operations, maintenance, and supporting functions from introducing unacceptable risks. Inadequate reviews of proposed changes can result in the potential for certain changes to violate the design basis of carefully engineered systems or to increase the risk of processes that have operated safely for years.

1.3.2 Industry Initiatives

Several industry organizations have recommended the development of MOC procedures through various guidelines (Table 1.4).

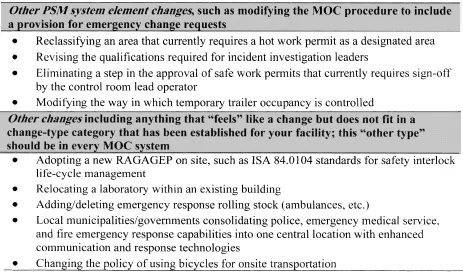

TABLE 1.3. Examples of Changes that Should Be Managed or Could Increase Risk

TABLE 1.4. Industry Initiatives to Implement MOC

| • American Chemistry Council Responsible Care Management System® 9 |

| • American Institute of Chemical Engineers Guidelines for Risk Based Process Safety 8 |

| • American Petroleum Institute Guidelines for Management of Process Hazards Recommended Practice 750 13 |

| • Canadian Chemical Producers Association Responsible Care Program, Manufacturing Code of Practices |

| • GE Corporation, Six Sigma – The Road to Customer Impact |

1.3.3 Regulatory Influences

Various U.S. and international government regulations require that changes to processes be reviewed. For example, the U.S. Congress has mandated that both OSHA and the Environmental Protection Agency (EPA) implement regulations that address accidents involving hazardous chemicals.3,10 The regulations issued by both of these agencies include MOC requirements. In February 1992, OSHA adopted a regulation, Process Safety Management of Highly Hazardous Chemicals (29 CFR 1910.119), which requires MOC as a key element of a complete PSM program. Specifically, the OSHA PSM regulation [paragraph (1)] includes the following requirements:

- Develop written procedures for managing change

- Address the technical basis for each change

- Evaluate potential safety and health impacts for each change

- Define requirements for authorizing changes to be made

- Appropriately inform and train affected employees and contractors before changes occur

In addition, OSHA requires that MOC systems specify the appropriate time period for the change (e.g., a change that is permitted for only 1 week) and that PSI, procedures, and practices be updated, as necessary, when changes occur.

In June 1996, EPA finalized its risk management program (RMP) rule. The accide...

Table of contents

- Cover Page

- Series Page

- Title Page

- Copyright Page

- Dedication

- Preface

- Acknowledgements

- Items on the CD Accompanying These Guidelines

- List of Tables

- List of Figures

- Acronyms and Abbreviations

- Glossary

- Executive Summary

- 1: Introduction

- 2: Relationship To Risk-Based Process Safety

- 3: Designing An Moc System

- 4: Developing An Moc System

- 5: Implementing And Operating An Moc System

- 6: Monitoring And Improving An Moc System

- 7: The Future Of Change Management

- Appendix A: Examples Of Replacements-In-Kind And Changes For Various Classes Of Change

- Appendix B: Moc System Design Structure

- Appendix C: Examples Of Moc System Procedure Work Flow Charts And Moc Review Documentation Forms

- Appendix D: Electronic Moc Applications

- Appendix E: Example Moc System Audit Checklist

- Appendix F: Example Moc Performance And Efficiency Metrics

- Appendix G: Common Moc Problems And Proposed Solutions

- References

- Index