![]()

CHAPTER 1

INTRODUCTION

Warning signs are indicators that something is wrong or about to go wrong. When we recognize and act on these indicators, a loss may be prevented. Of course, this will only happen when we know what to look for and are willing to take the initiative to do something about it. A review of significant incidents in the process industries suggests that most if not all incidents were preceded by warning signs. Some of these signs were clearly visible but not acted upon because their significance was not understood. Other warning signs were less obvious, but observant personnel may have detected them.

This book is about warning signs that have preceded or contributed to past incidents. There is one common characteristic shared by the incident warning signs presented here:

The organization does not perceive or recognize them.

An incident warning sign is a subtle indicator of a problem that could lead to an incident. Some minor incidents might have the potential to escalate to a catastrophic level. There are warning signs of a physical or tangible nature, and there are warning signs related to the management practices of an organization. Some warning signs may be problems in themselves while others may be symptoms of potential problems or incidents. Every sign provides a clue that may be an early warning of catastrophe. These clues give us an opportunity to do things differently to reduce the risk of a catastrophe.

It is common for an organization that experiences a major catastrophic incident to respond initially with shock and surprise. Somehow, facility workers and their supervisors may have developed the impression that catastrophic incidents only happen elsewhere and are the result of gross misconduct or total system breakdown. As the organization or local facility may have sustained itself without a catastrophic incident for many years, managers, technical staff, and facility workers often hold the sentiment… We must be doing things right. In many cases, this is a misguided perception. Consider taking a closer look at possible warning signs at your facility to avoid this experience.

The following quote from Professor Andrew Hopkins, an author on safety and professor of sociology at Australian National University, emphasizes the importance of addressing these indicators.

Prior to any major accident there are always warning signs which, had they been responded to, would have averted the incident. But they weren’t. They were ignored. Very often there is a whole culture of denial operating to suppress these warning signs.

The early warning signs we discuss either are unknown to the organization due to their lack of visibility or because the associated risk was unrecognized, downplayed, or ignored.

There are many types of warning signs, including the following:

- Early indicators of failure that provide opportunities to take appropriate action. Process equipment that is not functioning properly may be prone to failure. Organizations sometimes ignore these on the basis that they will address the issues later (or if the problem escalates).

- Suggestions that a major incident may be imminent. An example might include a piece of process equipment reaching its end-of-cycle or retirement limit.

- Indicators of other issues that are less obvious and require detailed analysis. For this reason, a practical follow-up option is to conduct an audit to help ensure that programs and systems are managed effectively.

- Seemingly insignificant issues that, when combined with other warning signs, suggest a breakdown of management systems.

- Actual incidents with measurable consequences. If we ignore these, they can increase in frequency or magnitude and contribute to a catastrophic incident.

Some of the warning signs discussed in this book are commonplace across the process industries. They may exist within your own operation or facility. Other significant warning signs may have been missed in our analysis and you may need to augment the list to make it more suitable to your organization’s needs. It would be rare to find a facility that does not have a warning sign present. When any warning sign becomes widespread or becomes the norm within an organization or when multiple warning signs are present, there is reason for concern. However, some warning signs might be inherent in your type of operation, and total elimination may be impossible or impractical.

Although some warning sign discussions do offer suggested approaches, the goal of this book is not to explain how to do it or how to fix the problem. We hope this book is a trigger for initiating self-assessment and follow-up action. It should help to alert responsible leaders that trouble may be on the way and, unless these warning signs are recognized and addressed, the probability of experiencing a major incident could increase.

1.1 PROCESS SAFETY MANAGEMENT

Process safety management (PSM) is a systematic framework of activities used to manage the integrity of hazardous operations and processes. Specifically, it deals with the prevention of loss of containment incidents that are commonly associated with the process industries. When hazardous materials are released outside their primary containment, especially to the atmosphere, the effects can be widespread and difficult to predict. Prevention is of paramount importance. Initiating proactive and systematic response to incident warning signs is a powerful tool to augment the standard elements of process safety. Determine your organization’s process safety philosophy. Ask the following question of your organization.

Do our actions related to process safety reflect that process safety is an integral part of our organizational culture?

Organizations that understand the importance of process safety will want to reflect that awareness in their actions. To be most effective, embrace rigorous process safety as a value throughout the organization and show it in the organization’s actions. Priorities change with the working environment or business climate. Values do not. They are something that a group internalizes and characterizes in its behavior to help define a framework for its actions.

1.1.1 Identifying process safety management system deficiencies

Less serious incidents precede most catastrophic incidents. Many of these less-than-catastrophic incidents can reveal early warning signs that could have prevented the catastrophic incident from occurring if leaders had recognized and acted upon them. Management system deficiencies are a root cause in all effective incident investigation methodologies. Our goal should be to identify common management system deficiencies and their associated early warning signs. We use case studies to illustrate these warning signs, and we hope to help you make a connection from these examples to your facilities. The case studies chosen are landmark events supported by thorough investigations. These catastrophes influenced how companies manage process safety activities worldwide.

Industry generally understands the central concept of designing and implementing management systems to maintain and improve performance. Process safety management embodies the following principles, although you may not recognize these as elements in your company’s program:

- Know your processes—both physically and in terms of information about them.

- Communicate process hazards effectively to all affected employees and contractors.

- Analyze the processes as necessary to understand them and their associated hazards.

- Operate the processes within their safe operating envelopes.

- Maintain the equipment properly in accordance with a documented asset integrity program.

- Manage and communicate all process changes over time.

- Train your employees and contractors on the processes and the associated hazards.

- Evaluate the operation regularly to see how you are doing.

- Get out into your facility so you can observe the visible warning signs and encourage site leadership to do the same.

- Develop the competencies and resources required by your business processes and process safety management system.

- Modify your business processes and management system as needed to meet changing requirements.

- Communicate the status of the facility’s activities and findings from any periodic reviews to the site senior management and others as appropriate.

- Develop action plans to address and close all findings.

When all workers see that the organization values and supports these types of systems, it encourages the employee’s individual commitment to safety and environmental excellence. The Center for Chemical Process Safety (CCPS) publication The Business Case for Process Safety demonstrates that a rigorous process safety framework also improves the bottom line.

Many of these management systems may already be in place in a high-hazard facility or operation. It is wise to consider extending these to all parts of an operation, regardless of the process hazards.

1.2 NORMALIZATION OF DEVIANCE

Normalization of deviance is a long-term phenomenon in which individuals or work teams gradually accept a lower standard of performance until the lower standard becomes the norm. It is typically the result of conditions slowly changing and eroding over time.

Normalization of deviance often begins in the form of a shortcut or poorly documented temporary change in a standard work practice or procedure. If there are no apparent negative consequences, the new practice becomes accepted and displaces the original practice. Over time, this process repeats. When the changes are small and seemingly insignificant, they are easy to miss. One subset of normalized deviance is organizational creep. This is a common term for this type of incremental change away from set work practices in an operating organization. In the midst of such change, it is sometimes difficult to recognize or appreciate the value of the original practice or procedure. Even when discussing this situation with local management, the news may be met with opposition in the form of comments like—it works just fine—or—it has not caused us any problems yet. Normalization of deviance represents a serious breach in the management of change system. It is also a major contributor to many serious incidents.

1.3 A STRATEGY FOR RESPONSE

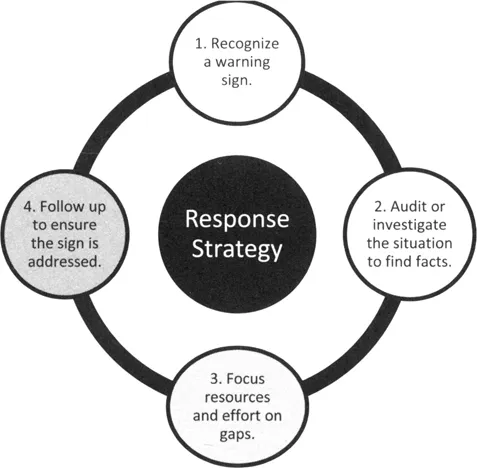

The response upon recognition of incident warning signs at your facility should not be a knee-jerk reaction but rather a disciplined approach to collecting all the facts and moving forward in a planned and organized manner. Figure 1-1 illustrates an approach to responding to an incident warning sign.

There may be a tendency in some organizations to deny the importance or significance of certain warning signs. This may be the case when these warning signs have existed for a considerable period without consequence. Some facilities may not consider a warning sign important if the entire staff has a high level of seniority and experience, and they have become complacent about plant operations. This indicates a false sense of security. Both new and senior workers may need training on the correct methods for doing things so that they develop a heightened sense of awareness regarding the importance of warning signs.

Professor Andrew Hopkins further states, “Organizational culture is one of the key factors why companies fail to recognize the warning signs prior to workplace accidents.”

An analysis of actual incidents may suggest that certain early warning signs correlate with specific types or categories of incidents. This assumption may not be valid. Managers need to take time to examine the local trends. They should stay close to day-to-day operations and not be lulled into complacency by short-term successes.

Finding multiple warning signs within your organization provides a more compelling reason to be concerned and to take action. Carefully screen the operation to determine system gaps or weaknesses. If these exist, are they universal or localized in one part of the operation? For example, procedural weaknesses can result in poor training. Likewise, inadequate training can result in inadequate written procedures. Analyze each detected sign carefully to ensure that you are fixing the right problem.

- Some of the warning signs may appear similar in context. While it is tempting to combine these, each might have a unique explanation or cause.

- Incident warning signs are unlikely to exist in isolation. Where a significant warning sign exists, chances are that other warning signs are present as well.

- It may be possible to rationalize a system weakness, but it is difficult to explain why so many things have gone wrong. This is why it is advisable to investigate further before initiating action.

Ultimately, all employees and contractors at a facility play a role in ensuring that the organization follows its programs rigorously and addresses all gaps. Addressing incident warning signs is a practice that...