![]()

Chapter 1

Use of Structural Steel

1.1 Why Steel?

Structural steel has distinct capabilities compared with other construction materials such as reinforced concrete, prestressed concrete, timber and brickwork. In most structures it is used in combination with other materials, the attributes of each combining to form the whole. For example, a factory building will usually be steel framed with foundations, ground and suspended floors of reinforced concrete. Wall cladding might be of brickwork with the roof clad with profiled steel sheeting. Stability of the whole building usually relies upon the steel frame, sometimes aided by inherent stiffness of floors and cladding. The structural design and detailing of the building must consider this carefully and take into account intended sequences of construction and erection. Compared with other media, structural steel has attributes as given in Table 1.1.

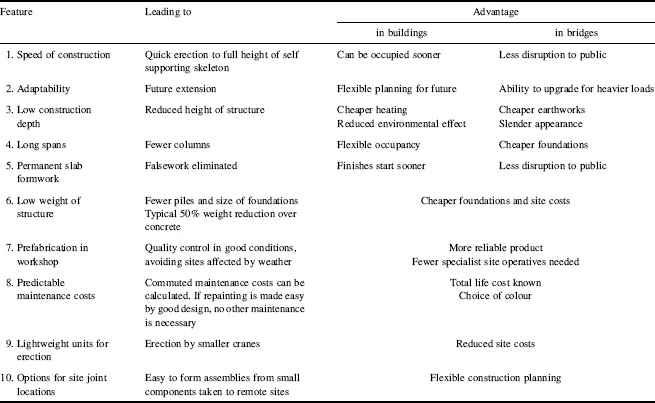

Table 1.1 Advantages of structural steel.

In many projects the steel frame can be fabricated while the site construction of foundations is being carried out. Steel is also very suitable for phased construction which is a necessity on complex projects. This will often lead to a shorter construction period and an earlier completion date.

Steel is the most versatile of the traditional construction materials and the most reliable in terms of consistent quality. By its very nature it is also the strongest and may be used to span long distances with a relatively low self weight. Using modern techniques for corrosion protection the use of steel provides structures having a long reliable life, and allied with use of fewer internal columns achieves flexibility for future occupancies. Eventually when the useful life of the structure is over, the steelwork may be dismantled and realise a significant residual value not achieved with alternative materials. There are also many cases where steel frames have been used again, re-erected elsewhere.

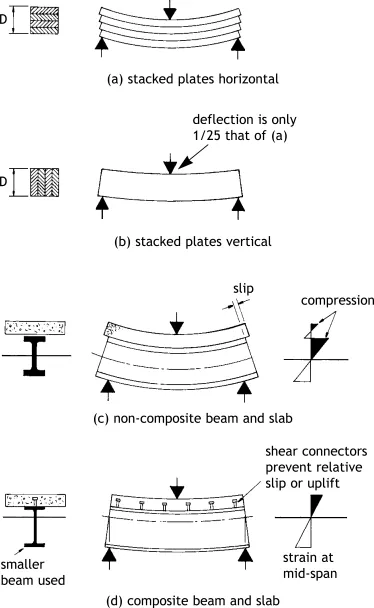

Structural steel can, in the form of composite construction, co-operate with concrete to form members which exploit the advantages of both materials. The most frequent application is building floors or bridge decks where steel beams support and act compositely with a concrete slab via shear connectors attached to the top flange. The compressive capability of concrete is exploited to act as part of the beam upper flange, tension being resisted by the lower steel flange and web. This results in smaller deflections than those to be expected for non-composite members of similar cross-sectional dimensions. Economy results because of best use of the two materials – concrete which is effective in compression – and steel which is fully efficient when under tension. The principles of composite construction for beams are illustrated in figure 1.1 where the concept of stacked plates shown in (a) and (b) illustrates that much greater deflections occur when the plates are horizontal and slip between them can occur due to bending action. In composite construction relative slip is prevented by shear connectors which resist the horizontal shear created and which prevent any tendency of the slab to lift off the beam.

Structural steel is a material having very wide capabilities and is compatible with and can be joined to most other materials, including plain concrete, reinforced or prestressed concrete, brickwork, timber, plastics and earthenware. Its co-efficient of thermal expansion is virtually identical with that of concrete so that differential movements from changes in temperature are not a serious consideration when these materials are combined. Steel is often in competition with other materials, particularly structural concrete. For some projects different contractors often compete to build the structural frame in steel or concrete to maximise use of their own particular skills and resources. This is healthy as a means of maintaining reasonable construction costs. Steel though is able to contribute effectively in almost any structural project to a significant extent.

1.2 Structural Steels

1.2.1 Requirements

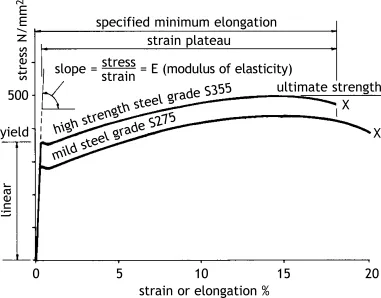

Steel for structural use is normally hot rolled from billets in the form of flat plate or section at a rolling mill by the steel producer, and then delivered to a steel fabricator's workshop, where components are manufactured to precise form with connections for joining them together at site. Frequently used sizes and grades are also supplied by the mills to steel stockholders from whom fabricators may conveniently purchase material at short notice, but often at higher cost. Fabrication involves operations of sawing, shearing, punching, grinding, bending, drilling and welding to the steel so that it must be suitable for undergoing these processes without detriment to its required properties. It must possess reliable and predictable strength so that structures may be safely designed to carry the specified loads. The cost : strength ratio must be as low as possible consistent with these requirements to achieve economy. Structural steel must possess sufficient ductility so as to give warning (by visible deflection) before collapse conditions are reached in any structure which becomes unintentionally loaded beyond its design capacity and to allow use of fabrication processes such as cold bending. The ductility of structural steel is a particular attribute which is exploited where the ‘plastic’ design method is used for continuous (or statically indeterminate) structures in which significant deformation of the structure is implicit at factored loading. Provided that restraint against buckling is ensured this enables a structure to carry greater predicted loadings compared with the ‘elastic’ approach (which limits the maximum capacity to when yield stress is first reached at the most highly stressed fibre). The greater capacity is achieved by redistribution of forces and stress in a continuous structure, and by the contribution of the entire cross section at yield stress to resist the applied bending. Ductility may be defined as the ability of the material to elongate (or strain) when stressed beyond its yield limit, shown as the strain plateau in figure 1.2. Two measures of ductility are the ‘elongation’ (or total strain at fracture) and the ratio of ultimate strength to yield strength. For structural steels these values should be at least 18 per cent and 1.2 respectively.

For external structures in cold environments (i.e. typically in countries where temperatures less than about 0 °C are experienced) then the phenomenon of brittle fracture must be guarded against. Brittle fracture will only occur if the following three situations are realised simultaneously:

(1) a high tensile stress.

(2) low temperature.

(3) A notch-like defect or other ‘stress raiser’ exists.

The stress raiser can be caused by an abrupt change in cross section, a weld discontinuity, or a rolled-in defect within the steel. Brittle fracture can be overcome by specifying a steel with known ‘notch ductility’ properties, usually identified by the ‘Charpy V-notch’ impact test, measured in terms of energy in joules at the minimum temperature specified for the project location.

These requirements mean that structural steels need to be weldable low carbon type. In many countries a choice of mild steel or high strength steel grades are available with comparable properties. In the UK as in the rest of Europe structural steel is now obtained to EN 10...