![]()

Chapter 1

Machining of Wood and Wood Composites 1

1.1. Introduction

While machining of wood has been conducted for many centuries, and significant progress has been made in the cutting of wood, the shape of the tool – wedge – has not changed. With the progress of the new tool materials, more abrasion resistant and durable blades are being introduced to machining.

The rapid development of composite wood products also causes the improvement of the techniques and machines used to process such materials. New theories regarding cutting help with better utilization of raw materials. Computerized control of the machines makes it easier to achieve the assumed quality and productivity.

1.2. Wood and wood-based composites

Although wood is well known to all of us, a compact characterization of this material can be useful before starting the analysis of wood machining aspects. Chemical composition of wood, depends, among other things, on its species, it is based on cellulose (about 45–55%), lignin (about 25–30%), hemicelluloses (10–20%), resins, rubbers (4.5–9.5%) and mineral contamination (about 0.5%). Because of the significantly higher share of cellulose and lignin only those two components are described below.

Cellulose, polysaccharide with a crystalline structure, is the main component of the cell wall structure. The molecules of cellulose are bonded together in long chains creating elongated fibers – micelles. In the free spaces between the bunches of micelles the lignin and water are stored. Cellulose is not water and alcohol soluble, and can be extracted from the cell wall only in an acid environment.

Lignin is an amorphous material, which fills the frame of the cell wall, and is fixed with cellulose mechanically and chemically. The presence of lignin makes the cell walls harder and stiffer.

In the macroscopic structure of wood the following elements can be found:

– pith;

– growth rings;

– sapwood;

– heartwood;

– rays;

– resin canals.

The pith is the physiological axis of the tree and is situated in the central part of the cross-section of the stem. The shape of the pith is characteristic of the tree species: star-shaped for oak, quadrangle for ash, triangular for alder.

Growth rings are the effect of the annual accumulation of the wood layer. Two areas can be found in the structure of growth rings: earlywood and latewood. The earlywood is lighter and is created during spring. The main function of this part of the growth ring is transportation. The anatomical elements of this part have thinner walls and larger dimensions, compared to the latewood. Latewood, which is darker, is created during summer and because of the mechanical functions has thicker walls. The softwood species have a larger earlywood area, and the latewood area mostly has a constant width. Hence, when the width of the growth rings increases, the density of wood decreases. In the case of hardwood species, mostly ring-porous, the width of the latewood increases with the increase of the growth ring width.

The variation of the growth ring width gives information about the climatic conditions during creation of those rings. The width of the growth rings depends on weather, climate and soil parameters, as well as on specific biological features of the species. The width of the growth rings varies between 1 and 40 mm and depends on the temperature and vegetation period length. It means that the same species, e.g. from the mountain biotope can have narrow growth rings, whereas trees from the lowland habitat have wide growth rings.

Sapwood is a biologically active zone which transports water and nutrients along the trunk.

Heartwood does not take part in transportation, because the vessels are plugged and the walls of the vessels are impregnated with resins, rubbers and tannins. The formation of heartwood depends on the tree age (e.g. 20–30 years for pine, 60 years for ash), soil and climate.

Rays are the complex of the cells, which accumulate and transport water with mineral salts inside the trunk.

Resin canals are thin tubes, which run along and across the trunk producing resin.

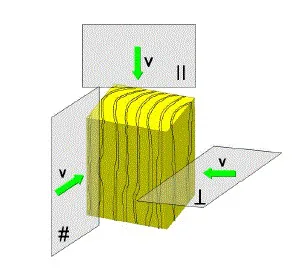

The structure of wood, which consists of elongated anatomical elements, influences its anisotropy, this means that the physical and mechanical properties differ in the three principal directions relative to the trunk of the tree.

The type of wood is one of the main factors, which has a great effect upon the machining. There are two major types of wood: softwood from needle-bearing trees, and hardwood from broad-leaved trees. The descriptions “soft” and “hard” have little to do with the hardness and density of wood.

The wood-based composite materials can be classified by the size of wood parts used to produce them. According to this, the following products can be found:

– plywood;

– OSB (oriented stradboard);

– particleboard;

– fiberboard.

Plywood is build up of thin sheets (plies) of wood (veneer), which are bonded together with glue under pressure. Plywood is produced mostly as flat panels or pre-shaped elements for furniture production. Plywood can be produced from either softwoods and hardwoods.

To achieve improved dimensional stability of plywood panels, they are usually constructed with an odd number of layers with the grain direction of adjacent layers oriented perpendicular to one another. This gives plywood fairly similar axial strength and stiffness properties in perpendicular directions within the panel plane. From the utilization point of view, two types of plywood are produced: construction and decorative. The production of structural engineered materials, e.g. I-joists, is the other use for plywood. The main technique of plywood processing is sawing.

Oriented strandboard (OSB) is the structural-use panel produced from thin wood (most often softwood) strands bonded with resin. Because of the strands' typical aspect ratio (strand length divided by width) of about 3, and the special orientation of the strands in the panel's layers, the OSB panel has a greater bending strength in the oriented directions. OSB panels are used mostly for roof, wall, and floor sheathing in wooden and prefabricated constructions, as well as for the elements in I-beams. Utilized as flat panels elements the OSB panels are mainly machined by sawing.

Typical furniture particle panel is produced in three layers. The core layer is made of the coarser material, which improves raw material utilization. Face layers, from the fine particles, give a smooth surface for laminating, overlaying or painting. The chips are bonded together mostly with amine resins, as urea-formaldehyde resin.

To improve the short-term moisture resistance of panels, paraffin or microcrystalline wax emulsion is added. Blended particles are pressed under elevated temperature and pressure. After pressing, the panel surfaces are sanded and can be finished and may also be veneered or overlaid with other materials to provide a decorative surface. The main ways of processing particleboards are circular sawing, milling (routing) and drilling.

The main difference between two types of fiberboard, hardboard and medium-density-fiberboard (MDF) is the method of mat formation: wet-method, where the fibers are moved in the water suspension and pressed with no bonding agent addition for hardboards; or the mat is formed by the pneumatic-mechanical method for MDF. The natural tendency of the lignocellulosic fibers to create larger conglomerates is utilized to produce hardboard.

During production of MDF, the fibers are blended with resin (mostly amine). The dry-formed group of panels, in addition to MDF, include high density fiberboard (HDF) and low density fiberboard (LDF). The main application of HDF panels are flooring materials, while LDF panels are used as wall facing. The furniture industry is by far the dominant MDF market, where it is frequently used in place of solid wood. The more regular structure of MDF panels across the thickness (compared to particleboards, for example) gives the opportunity for deep routing (milling) of the faces and shaping of the edges for the furniture fronts or doors. Sawing, milling, drilling, as well as deep routing are the most common ways of machining fiberboards.

1.3. Approach to cutting

Part of the tool, where the cutting is conducted, has a triangular shape. When the width of the machined material is smaller than the length of the cutting edge, free cutting is realized. In such a case only one cutting edge works. An example of free cutting is planing. If the width of the machined material is more than the length of the cutting edge, cleft cutting occurs. Apart from the main cutting edge, two side...