eBook - ePub

Gamma Titanium Aluminide Alloys

Science and Technology

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Gamma Titanium Aluminide Alloys

Science and Technology

About this book

The first book entirely dedicated to the topic emphasizes the relation between basic research and actual processing technologies. As such, it covers complex microstructures down to the nanometer scale, structure/property relationships and potential applications in key industries.

From the contents:

* Constitution

* Thermophysical Constants

* Phase Transformations and Microstructures

* Deformation Behaviour

* Strengthening Mechanisms

* Creep

* Fracture Behaviour

* Fatigue

* Oxidation Resistance and Related Issues

* Alloy Design

* Ingot Production and Component Casting

* Powder Metallurgy

* Wrought Processing

* Joining

* Surface Hardening

* Applications and Component Assessment

From the contents:

* Constitution

* Thermophysical Constants

* Phase Transformations and Microstructures

* Deformation Behaviour

* Strengthening Mechanisms

* Creep

* Fracture Behaviour

* Fatigue

* Oxidation Resistance and Related Issues

* Alloy Design

* Ingot Production and Component Casting

* Powder Metallurgy

* Wrought Processing

* Joining

* Surface Hardening

* Applications and Component Assessment

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

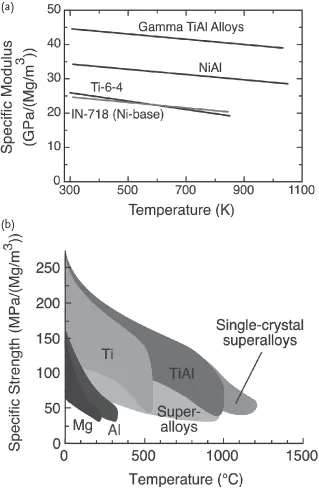

The reason why gamma TiAl has continued to attract so much attention from the research community including universities, publicly funded bodies, industrial manufactures, and end-product users is that it has a unique combination of mechanical properties when evaluated on a density-corrected basis. In particular, the elevated temperature properties of some alloys can be superior to those of superalloys.

Dimiduk [1] has assessed gamma TiAl with other aerospace structural materials and shown that new capabilities become available on account of its properties. The most important pay-offs involve

- high melting point;

- low density;

- high specific strengths and moduli;

- low diffusivity;

- good structural stability;

- good resistance against oxidation and corrosion;

- high ignition resistance (when compared with conventional titanium alloys).

Figure 1.1 shows how the specific modulus and specific strength of gamma TiAl alloys compare to other materials. As a result of these properties TiAl alloys could ultimately find use in a wide range of components in the automotive, aero-engine and power-plant turbine industries.

Figure 1.1 Graphs showing the (a) specific moduli and (b) specific strengths of TiAl and other structural materials, as a function of temperature [1]. The data indicates that TiAl compares favorably with the other materials. The data has been redrawn based on the original diagrams.

For a material to be ready for introduction, the whole production chain and supplier base, from material manufacture through processing and heat treatment must have achieved “readiness”. This includes detailed knowledge of how component properties are related to alloy chemistry, microstructure, and processing technology. In addition, TiAl-specific component design and lifing methodologies need to be developed and give reliable predictions [2]. At the implementation stage no unforeseen technical problems concerning the processing route or component behavior, which may be very costly to remedy, should arise. In 1999, a time when fuel costs were relatively low compared to the current day, Austin [3] discussed how introduction of gamma would depend on economic viability. This was identified as the chief obstacle for the use of gamma, with marketplace factors dominating implementation decisions.

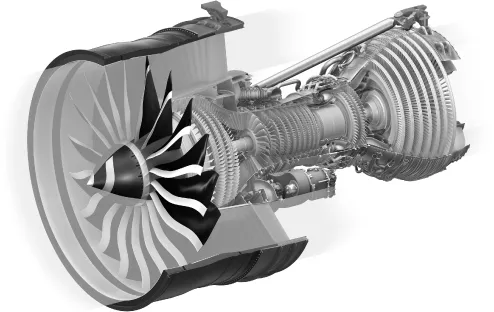

Due to its intermetallic nature, the complex constitution and microstructure, and the inherent brittleness, the physical metallurgy of TiAl alloys is very demanding. Nevertheless, we will attempt to discuss the broad literature that has been published over the last two decades concerning synthesis, processing and characterization. In our opinion, significant advances have been made, in particular General Electric has made public its intention [4, 5] to use gamma TiAl in its latest engine, the GEnx-1B (Figure 1.2), which best illustrates the present state that has been achieved in TiAl technology. Gamma TiAl has also been successfully introduced into at least one automotive series production, used in formula 1 racing engines, and a variety of components have been manufactured and successfully tested. In the following chapters we will present a comprehensive assessment of both the science and the related technology that has enabled TiAl to be used in the real world.

Figure 1.2 The General Electric GEnx-1B engine for the Boeing 787 Dreamliner. The blades in the last 2 stages of the low-pressure turbine in this engine are made from cast TiAl, making this engine the first to use TiAl in the real world.

Photo courtesy of General Electric.

References

1 Dimiduk, D.M. (1999) Mater. Sci. Eng., A263, 281.

2 Prihar, R.I. (2001) Structural Intermetallics 2001 (eds K.J. Hemker, D.M. Dimiduk, H. Clemens, R. Darolia, H. Inui, J.M. Larsen, V.K. Sikka, M. Thomas, and J.D. Whittenberger), TMS, Warrendale, PA, p. 819.

3 Austin, C.M. (1999) Curr. Opin. Solid State Mater. Sci., 4, 239.

4 Weimer, M., and Kelly, T.J. Presented at the 3rd international workshop on γ-TiAl technologies, 29th to 31st May 2006, Bamberg, Germany.

5 Norris, G. (2006) Flight International Magazine.

2

Constitution

2.1 The Binary Ti–Al Phase Diagram

The binary Ti–Al phase diagram contains several intermetallic phases, which represent superlattices of the terminal solid solutions and have been recognized to be an attractive basis for lightweight high-temperature materials for many years [1]. However, over the past two decades of research, only alloys based on the α2(Ti3Al) phase with the hexagonal D019 structure or the γ(TiAl) phase with the tetragonal L10 structure (Figure 2.1) have emerged as structural materials. Among these, interest has been strongly focused on γ titanium aluminide alloys, which, for engineering applications always contain minor fractions of the α2(Ti3Al) phase. Further, the high-temperature β phase with the bcc A2 structure and its ordered B2 variant (Figure 2.1) play a significant role in some engineering alloys. Despite intensive research, the binary Ti–Al phase diagram still remains a matter of debate and thus has been the subject of experimental work and critical assessment in recent years [2–5]. The impact of such work cannot be overestimated as a full understanding of the microstructural evolution in an alloy is limited by knowledge of the relevant phase equilibria. The discrepancies between different versions of the phase diagram might predominantly have been caused by the high sensitivity of phase equilibria to nonmetallic impurities, in particular oxygen [6–8]; but experimental difficulties, for example, problems in the identification of superlattices and sluggish phase transformations [9] may also play a role. Historically, investigations date back to the 1920s, as reported by Mishurda and Perepezko [6] and Schuster and Palm [2]. The first phase diagrams that covered the whole concentration range were published in the 1950s [10, 11]. More information on the historical development can be found in the article by Mishurda and Perepezko [6] cited earlier. The first critical and thorough assessment of the binary phase diagram was published by Murray [12] and has been considered as a standard reference [2]. Although Murray’s assessment does not reflect current knowledge on the phase equilibria in the Ti–Al system, it is a very useful compilation of phase diagram and physical data. Published experimental data was recently reassessed in a comprehensive study by Schuster and Palm [2]. This publication, together with the thermodynamic re-evaluations [3, 7–9, 13–15] constitute the current state of knowledge on this phase diagram. Figure 2.2 shows the phase diagram that was constructed by Schuster and Palm [2] after their critical assessment of all available experimental data. Figures 2.3 and 2.4 show sections of this diagram covering Al concentrations that are relevant for titanium aluminide alloys based on the γ(TiAl) phase. Experimental data has been plotted on these sections to give an impression on the reliability of phase boundaries. Figure 2.5 shows the most recent result for a thermodynamic evaluation of the binary Ti–Al phase diagram [3] obtained using the CALPHAD approach [16, 17]. Despite many similarities this diagram differs from that of Schuster and Palm [2], in particular for Al concentrations above 60 at.%. These discrepancies mainly arise due to the occurrence of the Ti3Al5 and Ti2+xAl5−x phases in the diagram of Witusiewicz et al. [3] and will be briefly discussed below. The crystallographic data of the stable and metastable phases considered by Schuster and Palm [2] and Witusiewicz et al. [3] are given in Table 2.1. Thermodynamic data and data on phase equilibria can be found in these two recent publications as well as in the references cited therein.

Table 2.1 Crystallographic data of phases occurring in the binary Ti–Al system.

The data has been taken from the publications of Schuster and Palm [2] and Witu...

Table of contents

- Cover

- Related Titles

- Title page

- Copyright page

- Preface

- Figures – Tables Acknowledgement List

- 1 Introduction

- 2 Constitution

- 3 Thermophysical Constants

- 4 Phase Transformations and Microstructures

- 5 Deformation Behavior of Single-Phase Alloys

- 6 Deformation Behavior of Two-Phase α2(Ti3Al) + γ(TiAl) Alloys

- 7 Strengthening Mechanisms

- 8 Deformation Behavior of Alloys with a Modulated Microstructure

- 9 Creep

- 10 Fracture Behavior

- 11 Fatigue

- 12 Oxidation Behavior and Related Issues

- 13 Alloy Design

- 14 Ingot Production and Component Casting

- 15 Powder Metallurgy

- 16 Wrought Processing

- 17 Joining

- 18 Surface Hardening

- 19 Applications, Component Assessment, and Outlook

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Gamma Titanium Aluminide Alloys by Fritz Appel,Jonathan David Heaton Paul,Michael Oehring in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.