- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book discusses the fundamental skills, techniques, and tools of auditing, and the characteristics of a good process safety management system. A variety of approaches are given so the reader can select the best methodology for a given audit. This book updates the original CCPS Auditing Guideline project since the implementation of OSHA PSM regulation, and is accompanied by an online download featuring checklists for both the audit program and the audit itself. This package offers a vital resource for process safety and process development personnel, as well as related professionals like insurers.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Edition

2Subtopic

Industrial Health & SafetyChapter 1

PROCESS SAFETY MANAGEMENT AUDIT PROGRAMS

1.1 PROCESS SAFETY MANAGEMENT (PSM) AUDITS AND PROGRAMS

Auditing is an element of a PSM program. It is a critical element in that it provides information about the effectiveness of the program and contributes to management control of other processes, systems, facilities, and safety and health programs. A sound PSM audit program will help improve the effectiveness of a PSM program.

In discussing PSM auditing, some confusion over terminology may arise. “Auditing” is used in various contexts to describe many different types of review or assessment activities. In this book, an audit is a systematic, independent review to verify conformance with established guidelines or standards. It employs a well-defined review process to ensure consistency and to allow the auditor to reach defensible conclusions. Other related activities sometimes referred to as audits include the following:

- Inspection. The process of physically examining a facility.

- Assessment, evaluation, and review. Less formal reviews, which may combine aspects of inspections and audits, are guided by the judgment, experience, and inclination of the reviewer, often without a well-defined review procedure or process. Such a review often has a broader scope than an inspection, but it does not have the consistency and rigor of an audit. At times, companies or facilities will use these three terms and other less formal terms in lieu of “audit,” but the activity has the same rigor as an audit, often the same protocol, the same way of using the protocol (i.e., interviews, record review, etc.), and the same reporting requirements. The reasons for using these terms interchangeably vary widely. Some companies have very strict rules governing any activity entitled “audit,” including legal governance. Some companies reserve the word “audit” to only those activities that are regulatory or compliance related.

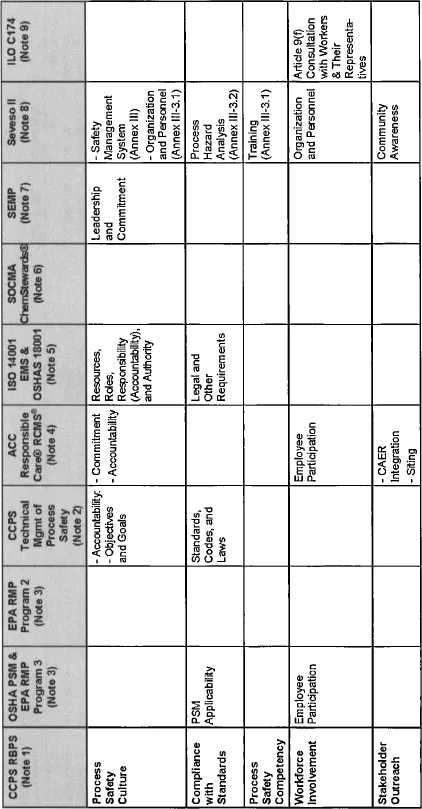

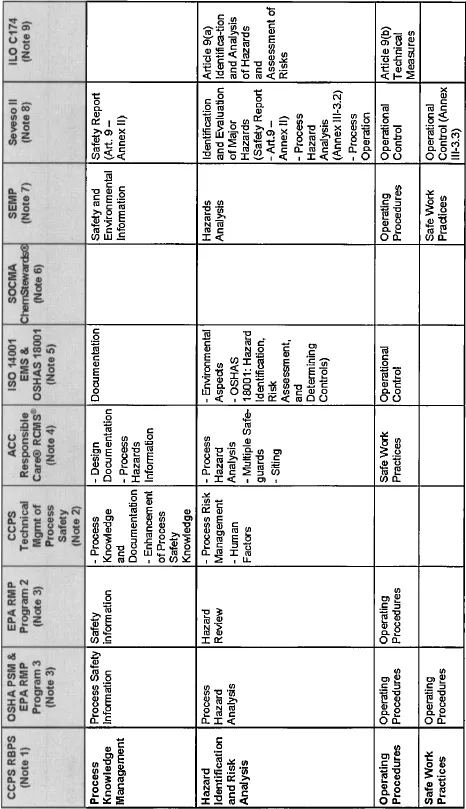

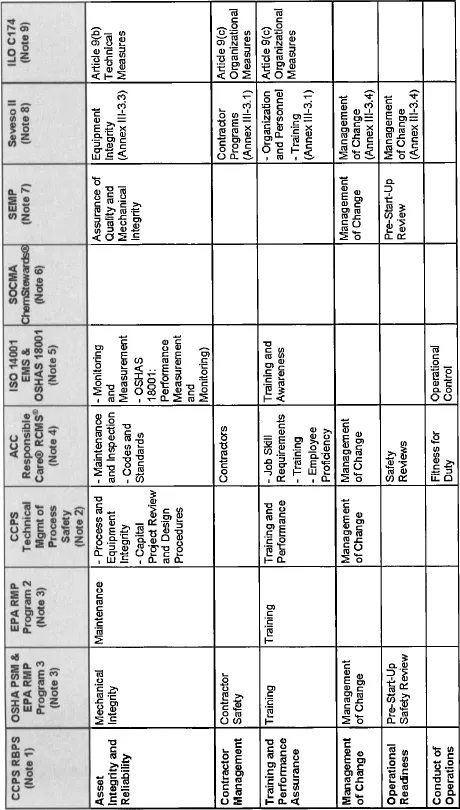

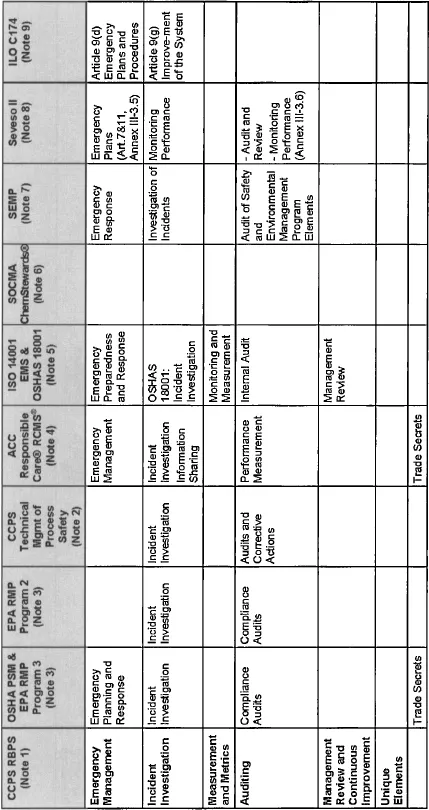

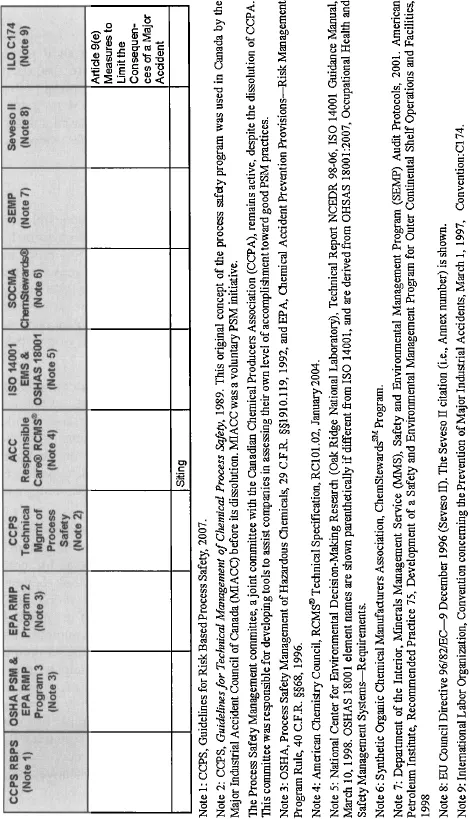

In its early publications (CCPS, 1989a and 1989b), the American Institute of Chemical Engineers’ Center for Chemical Process Safety (CCPS) defined 12 elements of a process safety management program. Subsequently, OSHA adopted the Process Safety Management Standard (OSHA, 1992), which contains 14 elements, and the applicability section of the standard. In 2007 CCPS revised the definition of a process safety management program in the publication of the Guidelines for Risk Based Process Safety (CCPS, 2007c) to include 20 elements. In addition, several states adopted process safety regulations before and after CCPS and OSHA established their programs, for example, New Jersey (NJ, 1987), California (CA, 1988), Delaware (DE, 1989), Washington (WA, 1992), Louisiana (LA, 1993), and Nevada (NV, 1994). Some states have simply adopted the OSHA PSM standard verbatim, or nearly so, while other states have added state-specific requirements. Several states have modified their state PSM programs to include the federal RMP Rule and obtain implementing agency status from the EPA to enforce the RMP Rule within their jurisdictions (e.g., Delaware, Florida, Georgia, Kentucky, Mississippi, New Jersey, North Carolina, Ohio, and South Carolina). California has its own state RMP regulation (the CalARP program), but it is not an implementing agency for the federal RMP Rule. Also, since the publication of the first edition of this book, a number of domestic and international governmental and nongovernmental organizations have developed and published PSM program requirements. Some of these have been mandatory requirements embedded in various regulations, and some have been voluntary standards representing the consensus of the publishing organization. Table 2.1 summarizes several of these various mandatory and voluntary process safety requirements. The table has been arranged so that comparable program elements are in the same row, recognizing that the detailed requirements between comparable elements may not be the same. Some of these programs have elements that have no corresponding element in another program and these have been placed at the bottom of the table.

For the purposes of the book, the elements published by CCPS in Guidelines for Risk Based Process Safety (CCPS, 2007c) have been used as a guide to describing a PSM program and its elements. Management systems that address each of these 20 elements should be established to form a comprehensive PSM program.

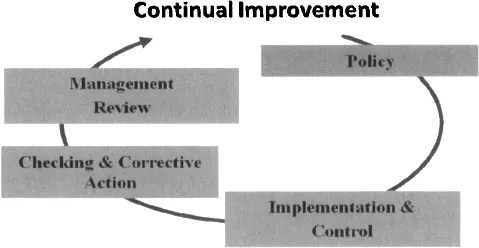

The ISO 14001 Standard defines a management system as “that part of the overall management system that includes organizational structure, planning activities, responsibilities, practices, procedures, processes, and resources for developing, implementing, achieving, reviewing, and maintaining the environmental policy.” Process safety management systems are comprehensive sets of policies, procedures, and practices designed to ensure that barriers to episodic and potential process safety incidents are in place, in use, and effective. EHS management systems, including those designed for PSM programs, typically follow closely the Plan-Do-Check-Act (PDCA) model used in many total quality management systems. A PDCA management system is founded upon the notion that continuous improvement is a cardinal principle. The “plan” portion of this model is essentially the development of written policies and procedures to define a desired program (in this case a PSM program). The “do” portion is where these policies and procedures are implemented (usually the most difficult step). The “check” portion is the evaluation or auditing of what occurs during the “do” step, while the “act” step involves taking what is learned and feeding the lessons learned back to revise the policies and procedures if necessary. This circular design with appropriate feedback is the key aspect of a PDCA management system and provides the continuous improvement. Figure 1.1 depicts a PDCA management system.

FIGURE 1.1 Plan-Do-Check-Act Management System

Process safety management auditing is the systematic review of these management systems to verify the suitability of these systems and their effective, consistent implementation. PSM audits are intended to determine whether management systems are in place and functioning properly to ensure operating facilities and process units have been designed, constructed, operated, and maintained to ensure that the safety and health of employees, communities, customers (to the extent that portions of the PSM program extend beyond the facility boundary, such as emergency response planning), and the environment are being properly protected. These audits are an important control mechanism within the overall management of process safety. In addition, these audits can provide other benefits such as improved operability and increased safety awareness. There are several items that are not included in the purpose or methods of a typical PSM audit:

- Focus on the programmatic aspects of PSM programs, not on identifying the equipment/process hazards. Process hazard analyses, hazard identification, risk assessments, and other similar activities are intended to determine the possible hazards and risk associated with the processes/equipment under consideration.

- Verify or replicate the engineering activities that took place to design the equipment and processes. For example, a PSM audit should not include within its scope work or activities that replicate the calculations performed to establish the set point and capacity of the relief devices in the processes. Engineering design reviews, design approvals, or the technical reviews associated with a MOC procedure are the appropriate places to perform this basic engineering work. A PSM audit would verify that the calculations have been performed and are in the facility’s files; the correct recognized and generally accepted good engineering practices (RAGAGEP) were used to design, install, and periodically test the relief devices; and the engineering design reviews or project approvals specified in the project manual/procedures were carried out and documented. This thin, but distinct line between auditing and engineering should be carefully observed. Audit teams have neither the time nor the expertise to perform basic engineering work, and it is always outside the purpose and scope of a PSM audit.

The criteria used during PSM audits, which will be used to evaluate PSM program, may be limited to the requirements of specific laws and regulations, or they may be broadened to include company policies and standards, or the guidelines of organizations described in Table 1.1. Each company should decide on appropriate audit criteria during the design of its audit program. The audit criteria are the reference points against which the PSM program will be compared to determine whether any deficiencies exist.

A PSM audit involves examination of management system design, followed by evaluation of management system implementation. The design of the management system must be understood and then evaluated to determine if the system, when functioning as intended, will meet the applicable criteria. Then the auditor must evaluate the quality and degree of implementation since a well-designed system may not be backed up by consistent, thorough implementation.

Table 1.1 Elements of Chemical/Processing Process Safety Programs

The remainder of this chapter discusses the issues associated with the design and management of a PSM auditing program. Specifically, the issues of audit scope, frequency, staffing, reporting, follow-up, and quality assurance are discussed. Although the concepts and guidance presented in this chapter are applicable in a general manner to all domestic and international facilities with PSM programs, there are some special issues that should be considered when U.S.-based auditors perform PSM audits in international locations. Appendix H provides additional guidance for international PSM audits.

1.1.1 Management Responsibilities and Accountability

Senior management at either the company or facility level is responsible for establishing the PSM audit program. Even if line management has been formally assigned the accountability for the design and implementation of PSM program, the auditing of the program is often considered a governance activity, and company-level policies and procedures are generally used to perform PSM audits. If the company has not established the necessary management systems to plan, execute, and document PSM audits, then the site management should assume these responsibilities. Management is responsible for the following aspects of the PSM audit program:

- Policy. Management should establish the overall policies that will control the audit activity. Responsibilities for actually planning, executing, documenting, reporting, and following up on the results can and should be delegated to appropriate personnel. Senior management, while retaining overall responsibility for the PSM audit program, should appoint a PSM audit “champion” with the appropriate background, experience, interest, and enthusiasm who will be responsible for planning and executing the details of the program.

- Commitment. Management should establish the proper philosophical tone for the audit program. This tone should emphasize the importance of the activity, what management hopes to learn from the audit about the PSM program in question, and the opportunity to look beyond regulatory compliance, if possible. The underlying tone should also ensure that all involved know that no personal blame will be attached to the results, but that the responsible parties will be accountable for the findings, particularly their correction (except for extreme situations where malfeasance is involved). Management should participate in the audit by attending debriefs and the opening and closing meetings, if time and schedules allow. This will allow the audit team and facility personnel to observe and understand management’s commitment to as well as their interest in the activity. PSM audits are intended to improve the program and reduce the likelihood of a process safety incident, and only senior management can convincingly convey this commitment message.

- Procedures. Management should establish and implement the appropriate management-system procedures for the PSM audit program. A typical PSM audit procedure should address the following topics:

– Selecting facilities for PSM audits

– Establishing frequency of PSM audits

– Planning and conducting audits, including scheduling

– Determining training and qualifications of auditors, including lead auditors

– Selecting and determining audit teams and assignment of the lead auditor

– Developing and maintaining the audit protocol

– Selecting focus units/processes and sampling guidance

– Documenting audits

– Following up on audit findings

– Determining format and content of audit reports

– Distributing and retaining audit reports

– Communicating audit results to the employees

– Providing access to employees of audit results

– Certifying audits (certification required by some process safety regulations)

This procedure, as with other PSM-related management procedures covering other PSM program elements, should be documented, formally issued, and approved for use.

- Resources. Management should commit the proper resources to execute the audit program. These resources should be formally budgeted on an annual or other budget-cycle basis. The resources needed include the following:

– Staffing and expenses associated with keeping the audit program up-to-date. Like any management system, it should be devis...

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- Acronyms

- Glossary

- Acknowledgements

- Preface

- User’s Guide to the Second Edition

- Executive Summary

- Introduction

- Guidance for Chapters 3–24

- Chapter 1: Process Safety Management Audit Programs

- Chapter 2: Conducting Process Safety Management Program Audits

- Chapter 3: PSM Applicability

- Chapter 4: Process Safety Culture

- Chapter 5: Compliance With Standards

- Chapter 6: Process Safety Competency

- Chapter 7: Workforce Involvement

- Chapter 8: Stakeholder Outreach

- Chapter 9: Process Knowledge Management

- Chapter 10: Hazard Identification and Risk Analysis

- Chapter 11: Operating Procedures

- Chapter 12: Safe Work Practices

- Chapter 13: Asset Integrity and Reliability

- Chapter 14: Contractor Management

- Chapter 15: Training and Performance Assurance

- Chapter 16: Management of Change

- Chapter 17: Operational Readiness

- Chapter 18: Conduct of Operations

- Chapter 19: Emergency Management

- Chapter 20: Incident Investigation

- Chapter 21: Measurement and Metrics

- Chapter 22: Auditing

- Chapter 23: Management Review and Continuous Improvement

- Chapter 24: Risk Management Programs

- Appendix A: PSM Audit Protocol

- Appendix B: PSM Audit Report Templates

- Appendix C: Sample PSM Audit Certifications

- Appendix D: PSM Audit Plan Templates

- Appendix E: Interview Questions for Nonmanagement Personnel

- Appendix F: PSM Audit Planning Questionnaire

- Appendix G: Integrated Contingency Plan (ICP) Audit Protocol

- Appendix H: International PSM Audits

- Appendix I: PSM Audit Dilemmas

- Appendix J: PSM Audits During Mergers and Acquisitions

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Guidelines for Auditing Process Safety Management Systems by in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Health & Safety. We have over one million books available in our catalogue for you to explore.