eBook - ePub

Refinery Engineering

Integrated Process Modeling and Optimization

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Refinery Engineering

Integrated Process Modeling and Optimization

About this book

A pioneering and comprehensive introduction to the complex subject of integrated refinery process simulation, using many of the tools and techniques currently employed in modern refineries.

Adopting a systematic and practical approach, the authors include the theory, case studies and hands-on workshops, explaining how to work with real data.

As a result, senior-level undergraduate and graduate students, as well as industrial engineers learn how to develop and use the latest computer models for the predictive modeling and optimization of integrated refinery processes.

Additional material is available online providing relevant spreadsheets and simulation files for all the models and examples presented in the book.

Adopting a systematic and practical approach, the authors include the theory, case studies and hands-on workshops, explaining how to work with real data.

As a result, senior-level undergraduate and graduate students, as well as industrial engineers learn how to develop and use the latest computer models for the predictive modeling and optimization of integrated refinery processes.

Additional material is available online providing relevant spreadsheets and simulation files for all the models and examples presented in the book.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Characterization, Physical and Thermodynamic Properties of Oil Fractions

This chapter introduces the common methods for characterizing crude oils and petroleum fractions (i.e., oil fractions), and for estimating their thermophysical properties. We begin by defining the essential bulk and fractional properties for oil fractions, and by explaining the various types of distillation curves and their interconversion (Section 1.1). Next, we discuss the generation of pseudocomponents of oil fractions based on boiling-point ranges, and the estimation of density and molecular weight distributions of the resulting pseudocomponents (Section 1.2). Sections 1.3 to 1.6 present four hands-on workshops using Excel spreadsheets and Aspen HYSYS Petroleum Refining for the interconversion of distillation curve data, the extrapolation of an incomplete distillation-curve data, the calculation of the mean-average boiling point of a given oil fraction, and specifying the oil fraction in Aspen HYSYS Petroleum Refining. Section 1.7 intro duces the essential thermophysical properties for developing refinery reaction and fractionation process models. Section 1.8 presents the useful methods for estimating the thermophysical properties (e.g., molecular weight, liquid density, critical properties, ideal gas heat capacity, and heat of vaporization) of pseudocomponents of oil fractions. Section 1.9 describes the important thermodynamic models for refinery reaction and fractionation processes. Section 1.10 discusses the estimation methods for other physical properties such as flash point, freeze point and PNA (paraffin, naphthalene and aromatic) content of a refinery feed. Finally, Section 1.11 summarizes the conclusions of this chapter.

1.1 Crude Assay

Crude oils and petroleum fractions are the most important feedstocks for refining processes. To properly simulate the refining processes, we must have good understanding of the compositional information and thermophysical properties of crude oils and petroleum fractions. However, the complexity of molecular composition of crude oils and petroleum fractions makes it hardly possible to identity individual molecules. Instead, modern refiners use assay to characterize crude oils and petroleum fractions.

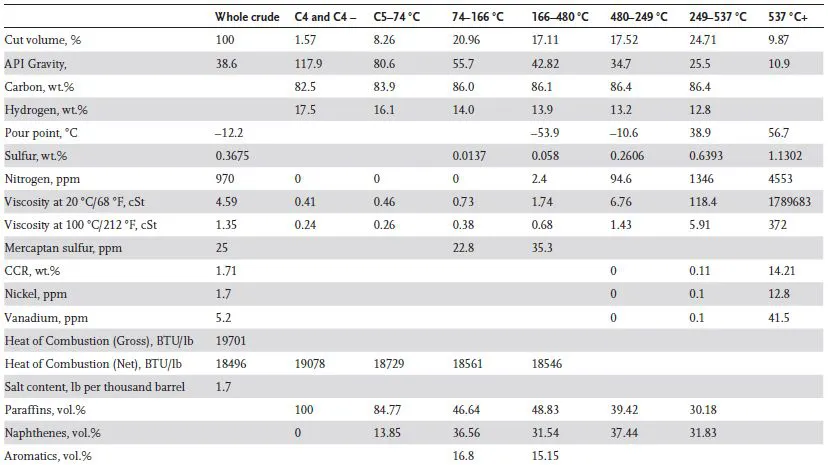

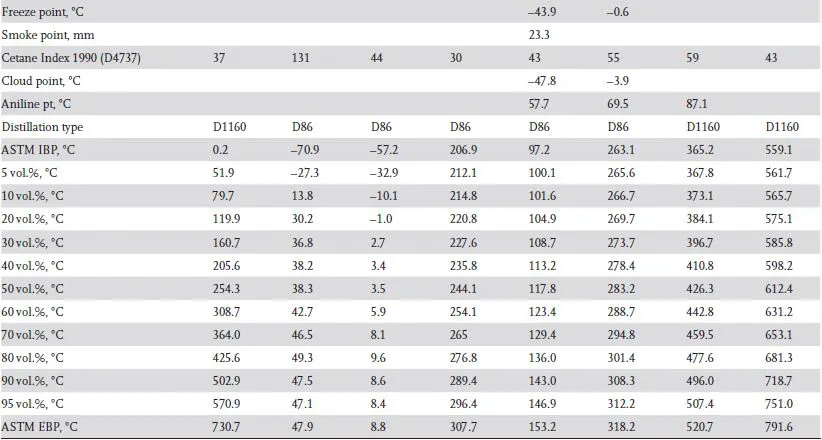

Table 1.1 A typical crude assay.

A typical crude assay includes two types of information for an oil sample: (1) bulk properties; and (2) fractional properties. Table 1.1 gives examples of both properties of a crude assay. For design and modeling purposes, it is always the best practice to have process data obtained in the same period as assay data, since the properties and composition of crude change over time as it is produced from a given well. Kaes [1] suggests that assay data should not be two years older than the process data used to build process simulation. We explain both bulk and fractional properties in the following subsections.

1.1.1 Bulk Properties

Bulk properties include specific gravity, sulfur content, nitrogen content, metal (Ni, V, Fe etc.) content, asphaltene content, C/H ratio, pour point, flash point, freeze point, smoke point, aniline point, cloud point,viscosity, carbon residue, light hydrocarbon yields (C1–C4), acid number, refractive index and boiling point curve. We generally use the API (American Petroleum Institute) gravity to specify the specific gravity (SG) of the crude oil as API = (141.5/SG) – 131.5. SG is the specific gravity defined as the ratio of the density of the crude oil to the density of water both at 15.6 °C (60 °F). The API gravity varies from less than 10 for very heavy crudes, to between 10 and 30 for heavy crudes, to between 30 and 40 for medium crudes, and to above 40 for light crudes.

The sulfur content is expressed as a percentage of sulfur by weight, and varies from less than 0.1% to greater than 5%. Crude oils with less than 1 wt.% sulfur are called low-sulfur or sweet crude, and those with more than 1 wt.% sulfur are called high-sulfur or sour crude. Sulfur-containing constituents of the crude oil include simple mercaptans (also known as thiols), sulfides, and polycyclic sulfides. Mercaptan sulfur is simply an alkyl chain (R–) with –SH group attached to it at the end. The simplest form of R–SH is methyl mercaptan, CH3SH.

The pour point is a measure of how easy or difficult to pump the crude oil, especially in cold weather. Specifically, the pour point is the lowest temperature at which a crude oil will flow or pour when it is chilled without disturbance at a controlled rate. The pour point of the whole crude or oil fractions boiling above 232 °C (450 °F) is determined by the standard test ASTM D97.

The flash point of a liquid hydrocarbon or an oil fraction indicates its fire and explosion potential, and it is the lowest temperature at which sufficient vapor is produced above the liquid to form a mixture with air that a spontaneous ignition can occur if a spark is present. One of the standard ASTM test methods for the flash point is D3278.

The freeze point is the temperature at which the hydrocarbon liquid solidifies at atmospheric pressure. It’s an important property for kerosene and jet fuels, because of the very low temperatures encountered at high altitudes in jet planes. One of the standard test methods for the freeze point is ASTM D4790.

The smoke point refers to the height of a smokeless flame of fuel in millimeters beyond which smoking takes places. It reflects the burning quality of kerosene and jet fuels, and is determined by the standard testing method ASTM D1322.

The aniline point represents the minimum temperature for complete miscibility of equal volumes of aniline and petroleum oil. It’s an important property of diesel fuels, and is measured by ASTM D611.

The cloud point refers to the temperature at which solidifiable components (waxes) present in the oil sample begin to crystallize or separate from solution under a method of prescribed chilling. It’s an important specification of middle distillate fuels, as determined by ASTM D2500.

The Conradson carbon residue (CCR) results from ASTM test D189. It measures the coke-forming tendencies of oil. It is determined by destructive distillation of a sample to elemental carbon (coke residue), in the absence of air, expressed as the weight percentage of the original sample. A related measure of the carbon residue is called Ramsbottom carbon residue. A crude oil with a high CCR has a low value as a refinery feedstock.

The acid number results from ASTM test method D3339-11 that determines the organic acidity of a refinery stream.

The refractive index represents the ratio of the velocity of light in a vacuum to that in the oil. It is determined by ASTM D1218.

The gross heat of combustion or high heating value (HHV) is the amount of heat produced by the complete combustion of a unit quantity of fuel. We obtain the gross heat of combustion by cooling down all products of the combustion to the temperature before the combustion, and by condensing all the water vapor formed during combustion.

The net heat of combustion or lower heating value (LHV) is obtained by subtracting the latent heat of vaporization of the water vapor formed by the combustion from the gross heat of combustion or higher heating value.

The true boiling point (TBP) distillation [1] of a crude oil or petroleum fractions results from using the U. S. Bureau of Mines Hempel method and the ASTM D-285 test procedure. Neither of these methods specifies the number of theoretical stages or...

Table of contents

- Cover

- Contents

- Series page

- Title page

- Copyright page

- Foreword by Steven R. Cope

- Foreword by Lawrence B. Evans

- Preface

- Acknowledgements

- About the Authors

- 1 Characterization, Physical and Thermodynamic Properties of Oil Fractions

- 2 Atmospheric Distillation Unit

- 3 Vacuum Distillation Unit

- 4 Predictive Modeling of the Fluid Catalytic Cracking (FCC) Process

- 5 Predictive Modeling of the Continuous Catalyst Regeneration (CCR) Reforming Process

- 6 Predictive Modeling of the Hydroprocessing Units

- Supporting Materials: List of Computer Files

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Refinery Engineering by Ai-Fu Chang,Kiran Pashikanti,Y. A. Liu in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Fossil Fuels. We have over one million books available in our catalogue for you to explore.